Material Versatility in CNC Machining: Adapting to Changing Manufacturing Demands

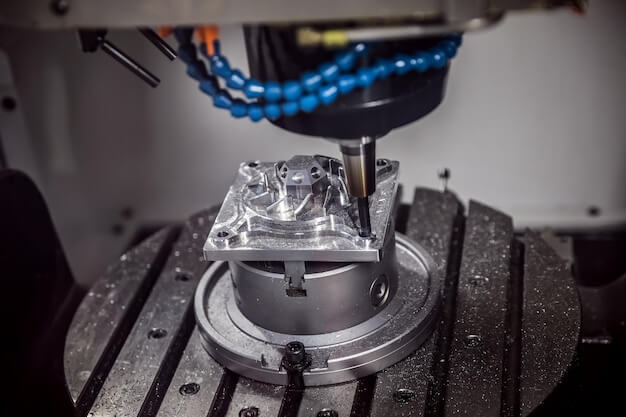

Material Versatility in CNC Machining and the Importance of Adapting to Changing Manufacturing Demands In the dynamic landscape of manufacturing, material versatility in CNC machining stands as a key determinant in meeting varying production requirements. This concept implies that Computer Numerical Control (CNC) machines have the capability to work with an extensive range of materials […]

CNC Machining in the Watchmaking Industry: Stainless Steel vs. Titanium Cases

CNC Machining and its Role in the Watchmaking Industry In the world of horology, CNC machining has proven itself to be an invaluable tool. This modern method allows custom parts to be generated with extraordinary precision – a key requirement in the construction of high-quality timepieces. Within this manufacturing process, materials play a crucial role […]

CNC Machining for Wearable Technology: Material Considerations for Comfort and Durability

Introduction to CNC Machining and Wearable Technology CNC (Computer Numerical Control) machining stands as a pivotal manufacturing process, adept at producing precision parts for a myriad of applications, including wearable technology. This process utilizes computerized controls and machine tools to remove layers from a solid block of material, shaping it into the desired form. The […]

CNC Machining for Energy Sector: Inconel vs. Titanium Alloys Performance Comparison

CNC Machining in Energy Sector: Inconel vs. Titanium Alloys The advent of CNC (Computer Numerically Controlled) machining has revolutionized the manufacturing industry, particularly within the energy sector. Known for its precision and ability to replicate components with accuracy, this mechanized process is pivotal in creating parts that are capable of withstanding extreme conditions often experienced […]

Metal 3D Printing Showdown: Titanium vs. Stainless Steel

Metal 3D Printing: An Introduction to Titanium and Stainless Steel 3D printing, otherwise known as additive manufacturing, refers to a process that creates three-dimensional objects from digital models. It’s used across various industries including automotive, aerospace, medical devices, and consumer goods for making prototypes, enhancing production efficiency, or fabricating complex structures. In the realm of […]

The Advantages of Titanium Alloys in Aerospace Manufacturing

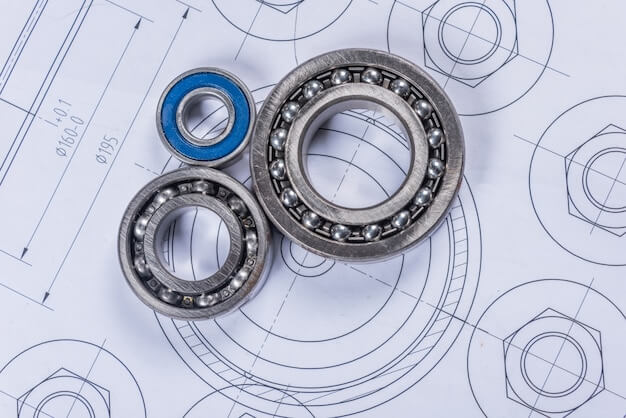

Aerospace Manufacturing and Materials In aerospace manufacturing, the key focus is on the fabrication of mechanical components designed for functions such as powered flight or navigation beyond Earth’s atmosphere. This high-tech sector plays a pivotal role in modern transportation and defense systems. In this context, materials used bear paramount significance influencing multiple aspects like weight, […]

Comparative Analysis: The Use of Ceramics vs. Hard Metals in Precision CNC Machining

Introduction: Understanding CNC Machining and the Importance of Material Selection CNC machining, an acronym for Computer Numerical Control, is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technique is predominantly used in the metalworking industry, allowing control over complex cutting tasks with precision and repeatability at high […]

Impact of Surface Roughness on CNC Machined Parts: Material and Process Variables

Introduction to CNC Machining and Surface Roughness CNC machining, abbreviated from Computer Numerical Control machining, is a manufacturing technique that uses pre-written computer software for dictating the movement of factory machinery and tools. Its primary application is in creating detailed instructions for intricate machinery operations, allowing smooth automation of complex tasks in production. The connection […]

Material Considerations in CNC Machining: Selecting the Right Substrate

CNC Machining and its Dependence on Material Selection The use of Computer Numeric Control (CNC) machining is deeply rooted in today’s manufacturing industry due to its exceptional capacity for precision, automation, and the wide-collection of materials it can effectively manipulate. CNC machining machines a material block into specified dimensions by exercising programmed instructions without manual […]

The Science Behind Material Removal Rates (MRR) in CNC Machining

Introduction: Understanding Material Removal Rates (MRR) in CNC Machining In the field of CNC machining, understanding the concept of Material Removal Rates (MRR) is critical. MRR defines the volume of material a cutting tool removes per unit time, usually measured in cubic inches per minute (in³/min). In other words, it denotes how swiftly a machine […]

CNC Machining for the Defense Industry: Titanium vs. Aluminum Alloy Selection

CNC Machining and Its Significance in The Defense Industry Computer Numerical Control (CNC) machining is a crucial manufacturing process whereby pre-programmed computer software dictates the movement of machinery and tools. It facilitates intricate and precise production, essential for the varied components used within the defense sector. CNC machining assures efficiency, repeatability, and accuracy vital to […]

The Engineer’s Choice: Titanium Grade 5 vs. Grade 23 for CNC Medical Implants

CNC Medical Implants: Material Choices and their Significance Computer Numerical Control (CNC) medical implants are an integral part of modern healthcare, designed with precision to replace missing or damaged body parts. With the unprecedented advancements in technology, customizing these implants for every patient’s unique needs has become possible, ensuring better health outcomes and faster recovery […]