Fast & Perfect Online 3D Printing Service

To provide faster and better custom machining services, Want.net offers a fast online 3D printing solution—the easiest way to source 3D prototypes and production parts. Take advantage of our powerful 3D printer network today!

- Instant Quote

- Fast Turnaround

- Pay After Delivery

- All uploads are secure and confidential

Premium 3D Printing Service Trusted by

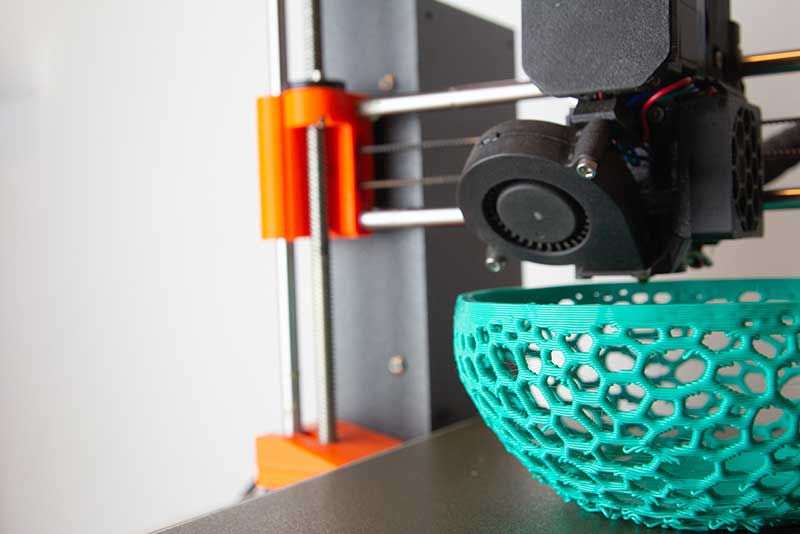

Rapid Prototyping with Our 3D Printing Service

3D printing is a perfect solution to develop your prototypes. It’s faster, cheaper, and more accurate. Unlike other manufacturing techniques, with 3D printing, you don’t have to develop a mold for prototypes. Your objects are created by digital mold with 3D software. That means huge amount of money and time will be saved. This makes Prototype Manufacturing more accessible, allowing you to experiment with multiple iterations efficiently. With 3D printing driving Prototype Manufacturing, you can bring ideas to life without the heavy upfront costs of traditional methods. So you can make all designs you want and test them at a lower cost.

Rapid 3D printed prototyping solutions from Want.net will allow you to create, test and refine in ways you never thought possible so you can go to market faster than ever.

One-Stop 3D Printing Service

As an on-demand online manufacturing platform, Want.net partners with hundreds of 3D printers in China. That means we are able to offer full-range 3D printing services for our global customers. We source and stock the materials at a large scale and optimize the production processes to ensure our prices are competitive within the industry. And our quality control experts will inspect all 3D printed parts before shipping. We are your 1-stop online 3D printing company.

Our 3D Printing Service Capabilities

Online 3D printing services allow users to upload any kind of 3D model or idea to print and supplied directly to their doorstep. Typically, a 3D model is sent to our team for an instant quote.

Customers who use online 3D printing services can have 3D models printed in a variety of materials and their choice of colors and finishes. This service is useful in engineering, production, and product design since it lets companies produce and test prototypes without the use of expensive equipment.

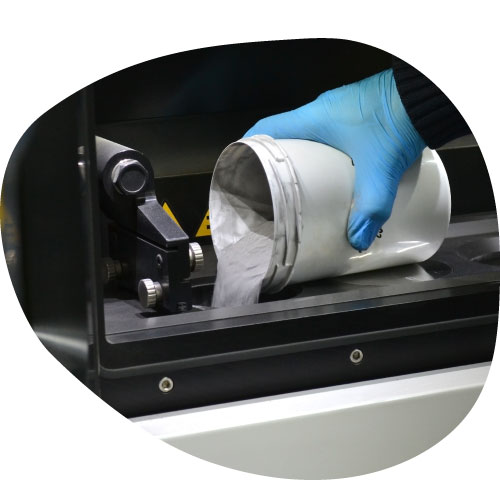

SLA

The Stereolithography (SLA) printing process impresses in particular with its smooth and detailed surfaces, as well as its high level of accuracy.

SLS

Selective Laser Sintering (SLS printing) with PA plastics enables stable and close-to-production functional models.

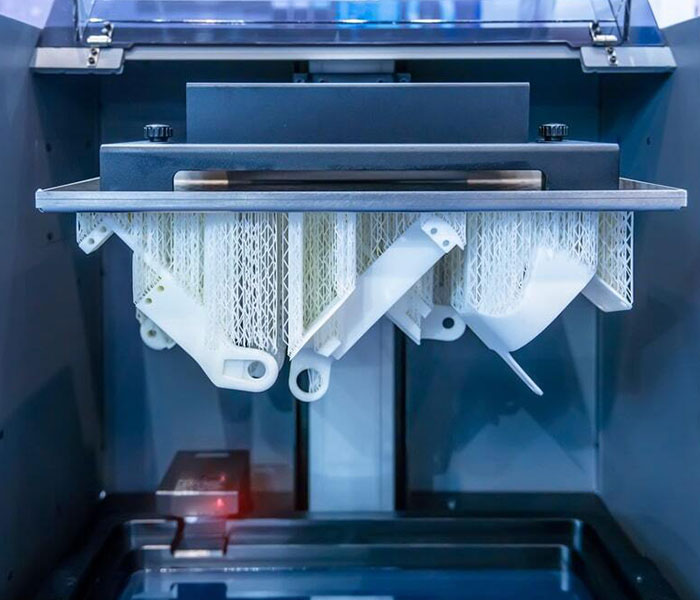

FDM

Fused Deposition Modeling (FDM process) is a 3D printing process developed by the American Scott Crump in the late 1980s, which is now one of the most popular 3D printing methods .

Custom 3D printing is a complex process that demands a high level of knowledge and proficiency. Professional services offer a wide range of services, including design, prototyping, and production, and can deliver the greatest materials and outcomes. Professional services can also provide access to cutting-edge equipment and resources, enabling the creation of solutions that are especially suited to each client's demands. Additionally, professional services can offer individualized client support and assistance throughout the complete process of 3D printing.

Huajian - CEO of Want.net

Get Quote For Your 3D Printed Parts Today!

Custom 3D Printing Standards

Available Finishing Options for 3D Printing

The process of painting finish will give colour to the surface of the material in any of the available paints with specific RAL. The colours are spread on the material using a spray gun, allowing a uniform and smooth surface. paint is very durableand retains the same shade without losing intensity. Since we use a cellulose paint, there is no risk once it dries of staining clothing or your skin. It is therefore suitable for all uses.

Polishing is a process that makes the objects smoother to touch, with layers still somewhat visible on rounded objects. The polishing process can be automated by machine or manually by hand. Our polishing is carried out with rotary polishing machines.

Powder coating is one of the most durable finishes that can be applied to your 3D-printed parts. Unlike conventional liquid paint, delivered via an evaporating solvent, powder coating is typically applied electrostatically and cured under heat or with ultraviolet light.

Bead blasting is a finishing technique for 3D-printed parts. It’s an abrasive blasting method, which means that it is similar to sandblasting and water blasting (pressure washing). In bead blasting, fine beads of plastic, glass, or another substance are forcibly sprayed over the surface of a part. The type of beads are chosen depending on the part’s material in order to smooth the finish of the part without damaging it.

What You Can Do with Want.net's Online 3D Printing Service?

We at Want.net offers a full range of additive manufacturing solutions for all applications, from single components for rapid prototype to intricate functional parts for larger-scale production. Our online 3D printing service enables you to turn your design into reality in a faster way; by creating complex prototypes or final parts before mass production, you can speed up your product development cycle and save the cost that was previously impossible with traditional manufacturing.

From a sketch to the final 3D printed product, Want.net allows you to choose the latest technology for 3D printing; We have built a robust network of 3D printing manufacturers in China focusing on four major technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). We stock various materials and optimize the ordering and production processes to minimize costs at every step. In that way, we can eventually offer our customers the most competitive 3D printing price.

Ordering 3D Prints is easy with Want.net. Upload your 3D models, and our system will instantly analyze your file and get back to you with feedback and a quote. Once we get your approval, your order will be processed by one of our 3D printing manufacturers on the same day. We will inspect everything before we send them to you. You are totally risk-free with our one-stop online 3D printing service.

Best Online 3D Printing Service in China

Instant Online 3D Printing Quotes

Our online 3D printing quote system works in the following ways:

- Visit our online 3D printing service quote tab.

- Choose the type of urgent 3D printing service you require and upload your 3D model.

- Enter the material, finish, and minimum quantity for your 3D print.

- Submit your request and receive an instant online 3D printing quote.

3D Printing Services for Hobbyists

Online 3D printing services are generally accessible to hobbyists. Numerous companies provide 3D printing services, such as SLS printing, SLA printing, FDM printing, and others. You can select our online 3D printing service that satisfies your requirements based on the type of material, the size, and the intricacy of the object.

What is 3D Printing?

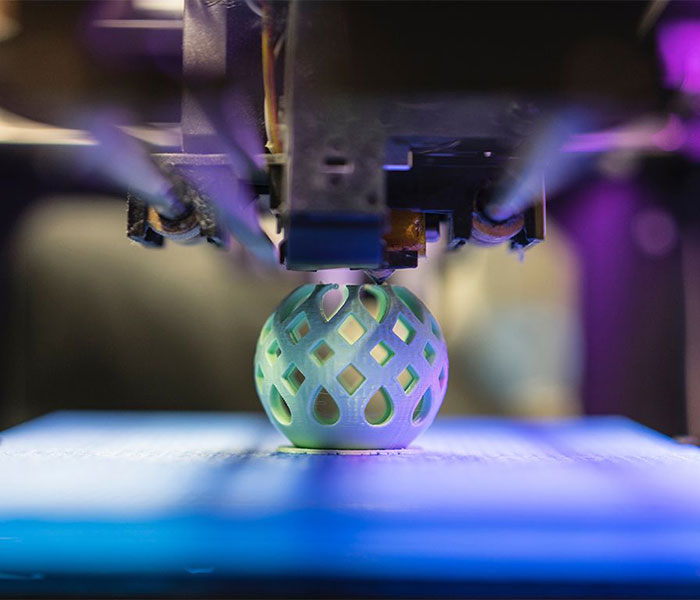

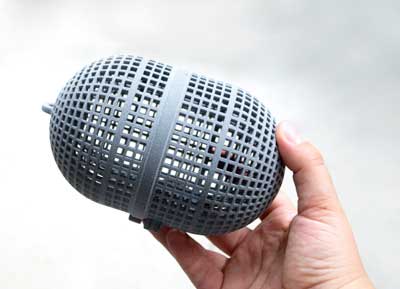

3D printing is based on advanced technology which is known for the manufacturing of three-dimensional objects from digital designs and ideas. It works by adding materials in layers until the required shape is produced. A wide variety of objects, from useful components to decorative pieces, can be created with 3D printing.

3D printing is based on advanced technology which is known for the manufacturing of three-dimensional objects from digital designs and ideas. It works by adding materials in layers until the required shape is produced. A wide variety of objects, from useful components to decorative pieces, can be created with 3D printing.

The features of 3D printing are limitless, and they have made it feasible to construct complex structures and designs that were previously impossible. It has made it possible to create prototypes for several industries, including manufacturing and aerospace.

Additionally, prosthetic limbs, personalized jewelry, and medical implants have all been produced via 3D printing. A wide range of opportunities for companies, people, and even entire sectors have been created as a result of the quick and simple creation of customized items through 3D printing.

What is the 3D Printing Process?

3D printing is a process for producing solid three-dimensional items from digital files. Additive methods can be used to produce 3D-printed objects. In this method, progressively shaped material layers are laid down.

- The process starts with a 3D model of the object being created with CAD software or a 3D scanner.

- Afterward, the 3D CAD model is divided into thousands of horizontal layers.

- The 3D printer then adds material to each layer, one at a time, until the entire item is created.

- A computer scans the digital model and operates the 3D printer by giving instructions.

- Next, the product is heated, dried, cured, and finished, based on the material used.

- The process is ended when the finished product is taken out of the 3D printer.

What Is 3D Printing Used For?

3D printing is the technique of turning a three-dimensional computer model into a physical object. It is used to make products with precise details and complex designs out of a variety of materials, such as plastic, metal, and composites. Custom parts, prototypes, finished goods, as well as art, jewelry, clothing, etc. can all be produced with 3D printing.

What Are Common 3D Printing Applications?

What Are Common 3D Printing Applications?

- Prototyping: Rapid prototyping of parts using 3D printing is very popular and enables engineers and designers to test functionality and make quick changes to their designs.

- Manufacturing Tools: 3D printing can build specialized tools, molds, and fixtures for manufacturing lines and machinery.

- End-Use Parts: End-use parts including mechanical parts, electronics, and medical equipment can be produced via 3D printing to produce usable pieces.

- Education: 3D printing can quickly create models and prototypes for colleges and universities for teaching and learning.

- Art & Architecture: The creation of unique works of art and architectural models is possible with 3D printing.

Advantages of 3D Printing

- Cost-Effective: 3D printing is a low-cost method of producing parts and models because 3D printing replaces conventional production procedures including tooling, injection molding, and machining.

- Fast Turnaround Time: The turnaround time for a project is significantly shortened by 3D printing. Long lead times associated with conventional manufacturing techniques can be avoided by printing parts fast and without the requirement for manual assembly.

- Better Customization with Design: Designers can use 3D printing to build intricate designs and patterns that would be impractical or impossible to produce using conventional manufacturing procedures. As a result, product design can be more innovative and creative.

- Eco-Friendly: Compared to traditional manufacturing methods, 3D printing generates a lot less waste. Plastic is the most common material used in 3D printing, and plastic can be recycled. Additionally, tooling is not needed with 3D printing, which reduces waste and can be rather expensive.

- Customization: Products can be quickly customized via 3D printing to meet a customer’s exact needs. This is particularly helpful for creating products with intricate geometries or unique characteristics.

Online 3D Printing FAQs

Want.net is the cheapest 3d printing service company that offers tailored solutions for small and large batch orders. Send us your requirement and let our sales staff quote the best price for 3d printing.

The cost of 3D printed parts depends on your parts’ quantity, material, and complexity. To get an exact quote for your project, please send us your 3D file.

To reduce the cost of your 3d prints, choosing low-cost materials like PLA, ABS or PETG is a good option as compared to costly materials like metal or nylon. Similarly, if you order in bulk, you can reduce the cost of your 3d prints also.

You should provide your CAD (.STL) file for our analyse. If your file is in other formats, you should convert it before sending it to us.

Lead time for 3D printed parts depends on the complexity of the job. We can complete your 3D printing order as quickly as one day for the simple structure. We will inform you of the exact lead time when you get your 3D file.

Put Your 3D Printed Parts into Production Today!

You’re one-step away from the most affordable injection molding service. Fill the form beside and we will get back to you within 24 hours.

GET QUICK QUOTE

- All uploads are secure and confidential