China Online CNC Machining Services

Want.net provides online CNC machining services in China. Want.net partners with hundreds of CNC factories across China to offer the highest precision in online CNC machining for your custom parts or prototypes. Get your free quote today!

- Instant Quote

- Fast Turnaround

- Pay After Delivery

Home » CNC Machining » China CNC Machining

CNC Machining Services

Looking for dependable and swift CNC machining services? Look no further!

Want.net Team cutting-edge CNC technologies to deliver top-notch results promptly. With a blend of skilled machinists, engineers, and quality control experts, we ensure that your products are crafted to perfection and delivered on schedule.

Our ISO 9001:2015 certified CNC manufacturing facility is optimized for rapid prototyping and low-volume production across a diverse array of components.

Moreover, our CNC machining services seamlessly integrate with our other manufacturing capabilities, such as 3D printing and injection molding, offering you a comprehensive manufacturing solution.

From straightforward to intricate precision machined parts, we handle a wide spectrum of materials and surface finishes with precision and finesse.

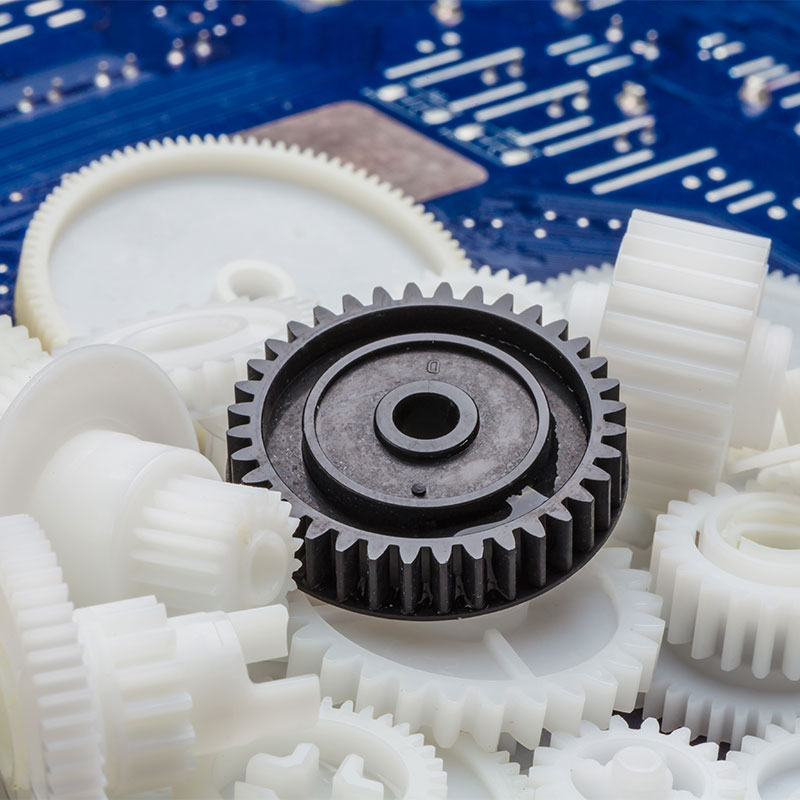

High Precision CNC Machined Parts

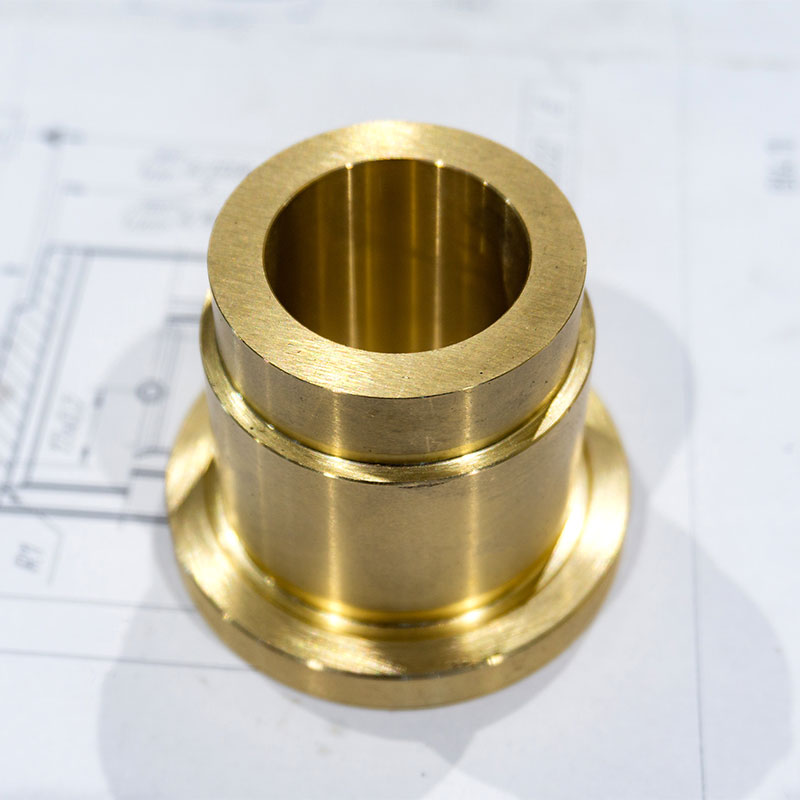

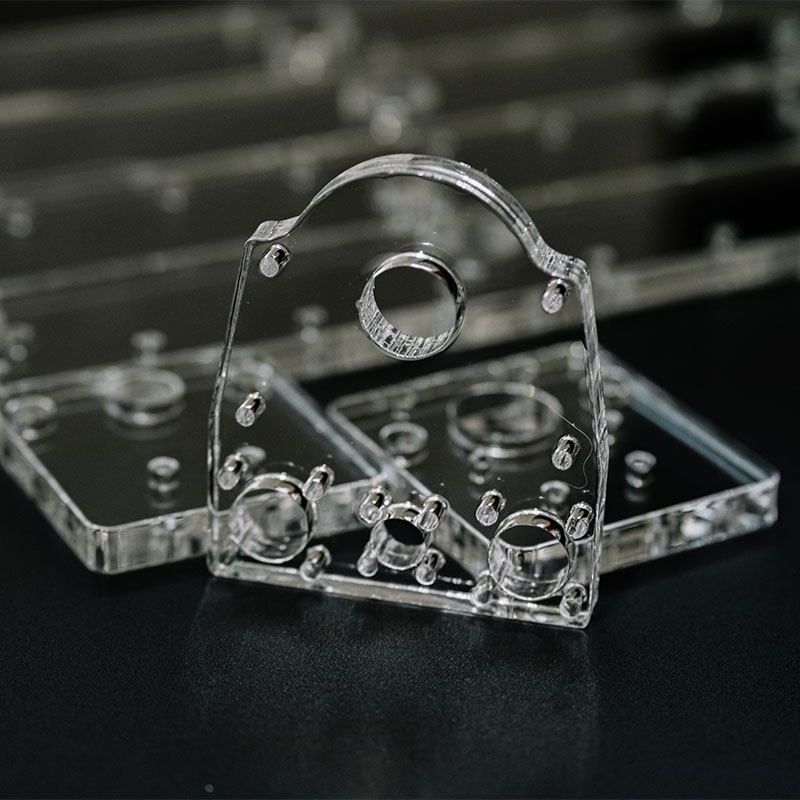

CNC machining offers a wide array of capabilities for crafting high-precision parts. For example, CNC milling machines excel at creating intricate features such as cavities, angled shapes, holes, and slots.

On the other hand, CNC lathes are adept at producing cylindrical shapes or parts with symmetrical features near their axis.

Both CNC milling and turning machines can achieve remarkably tight tolerances, reaching as precise as ±0.001mm.

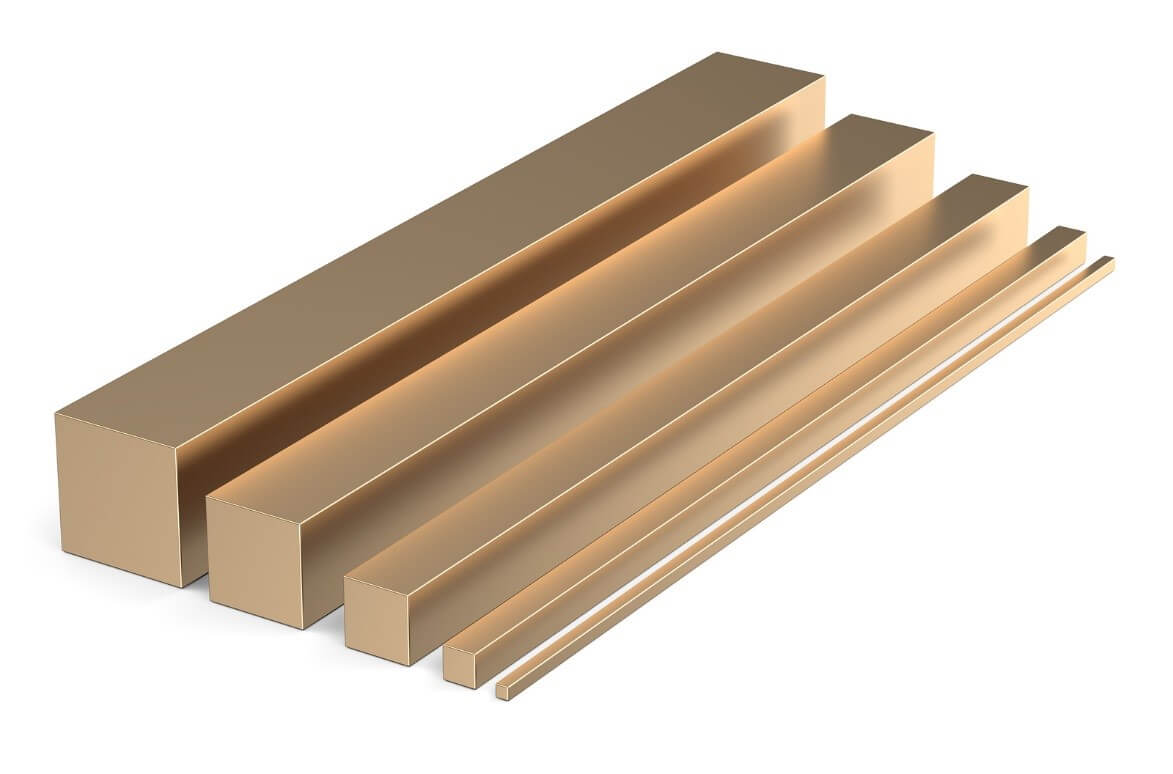

Furthermore, they accommodate a diverse range of materials, including metals and plastics, provided these materials are available in block form. This stands in contrast to additive manufacturing technologies like 3D printing, which are limited to plastics and a select few metals.

Our CNC Machining Capabilities

Advantages of CNC machining in China

1. Advanced Technology and Infrastructure

China boasts cutting-edge technology and a well-developed infrastructure for CNC machining. The country has heavily invested in research and development, leading to the establishment of state-of-the-art facilities equipped with high-precision CNC machines. These machines are capable of producing intricate parts with utmost accuracy and efficiency. Moreover, China’s extensive network of transportation and logistics ensures smooth operations and timely delivery of products to customers worldwide.

2. Cost-Effectiveness and Competitive Pricing

One of the key advantages of CNC machining in China is its cost-effectiveness and competitive pricing. The country’s large-scale manufacturing capabilities, coupled with economies of scale, enable manufacturers to offer products at lower costs compared to many other regions. Additionally, China’s abundant skilled labor force and relatively lower labor costs contribute to cost savings without compromising on quality. As a result, businesses can leverage CNC machining services in China to reduce production expenses and enhance their competitiveness in the global market.

3. Wide Range of Materials and Finishes

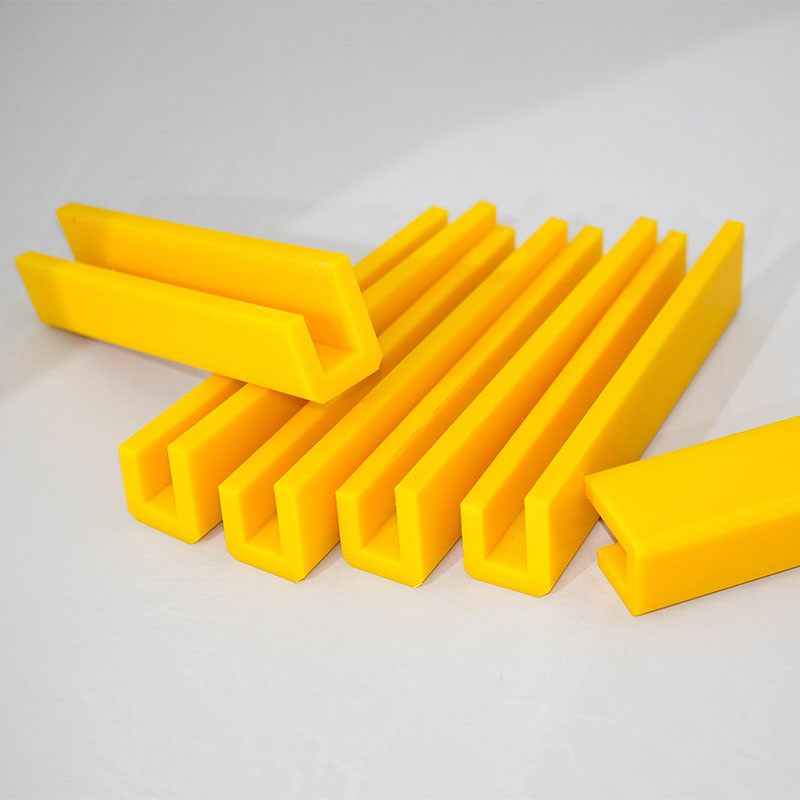

China’s CNC machining industry offers a diverse range of materials and finishes to meet various customer requirements. Whether it’s metals like aluminum, stainless steel, or titanium, or engineering plastics such as ABS, PEEK, or Nylon, Chinese manufacturers have the expertise and capability to work with a multitude of materials. Furthermore, they provide a plethora of surface finishes, including anodizing, powder coating, plating, and polishing, allowing customers to customize their products according to specific aesthetic and functional needs.

4. Flexibility and Scalability

CNC machining services in China offer unmatched flexibility and scalability to accommodate the evolving needs of businesses. From prototyping and small-batch production to mass manufacturing, Chinese manufacturers can handle projects of different scales with agility and precision. Moreover, they are adept at rapid tooling and quick turnaround times, enabling faster product development cycles and time-to-market. Whether it’s a startup looking to launch a new product or a multinational corporation seeking to streamline its supply chain, China’s CNC machining industry provides the flexibility and scalability required to succeed in today’s dynamic business landscape.

In conclusion, CNC machining in China presents numerous advantages, including advanced technology and infrastructure, cost-effectiveness, a wide range of materials and finishes, as well as flexibility and scalability. By leveraging these strengths, businesses can benefit from high-quality precision parts, competitive pricing, and efficient production processes, making China a preferred destination for CNC machining services.

1. Cost-effectiveness: China offers competitive pricing for CNC machining services due to lower labor and operational costs compared to many Western countries.

2. Advanced technology adoption: Chinese CNC machining facilities often invest in state-of-the-art equipment and technologies, staying at the forefront of industry advancements to ensure high-quality output.

3. Skilled workforce: China boasts a large pool of skilled machinists and engineers with expertise in CNC machining, enabling efficient production and precise machining of complex parts.

4. Scalability and flexibility: Chinese CNC machining companies can handle a wide range of production volumes, from prototyping to mass production, offering flexibility to accommodate various project sizes and timelines.

Comparative Analysis: Injection Molding vs. Transfer Molding – Which Technique is Superior?

Plastic and rubber parts are a common sight in the industry. Most of these parts are made through molding techniques, with injection and transfer molding

High-Speed CNC Machining Parts: The Secret Sauce of Tool Material Selection

To high-speed CNC machining, the selection of tool materials is crucial. Imagine you’re a chef preparing a gourmet meal; the ingredients you choose will significantly

Heat Treatment Insights for Wrought Aluminum Alloys in CNC Machining Parts

In the field of CNC machining, achieving the desired mechanical and physical properties often hinges on effective heat treatment. For wrought aluminum alloys, which are

Revealing the Annealing Process of Copper and Alloys in CNC Machining Parts

In the realm of CNC machined parts, achieving the perfect balance of strength, flexibility, and durability often requires meticulous heat treatment processes. One such crucial

CNC Machining and Sheet Metal Processing in the Automotive Industry: Driving Innovation and Precision

Since its beginnings in the 1860s, the automotive industry has built itself on continuous innovation and technology advancements. One of the most significant drivers of

High-Speed Cutting in CNC Machining Parts: The Power of TiC(N)-Based Hard Alloys

To CNC machining, the choice of tool material is crucial, especially for high-speed cutting. TiC(N)-based hard alloys have emerged as a game-changer, offering a unique

China CNC Machining Metal

China CNC Machining Plastic

China CNC Machined Parts

We offer top-notch China CNC machining services for a wide range of parts. Our CNC machining capabilities enable us to deliver precision-engineered components with exceptional accuracy and quality.

Why Choose Our Online CNC Machining Service in China

China CNC Machining FAQs

The cost of your CNC machining project depends on some factors such as the design, tolerance require, material, machining times, and human resources that have to be input into the project. You can send us your CAD file so we can prepare the quote for you.

- Select The Right Machining Process: One of the best techniques to reduce the cost f CNC machining is to choose an efficient machining process. Generally, you need a professional machining company that will guide you through the complete CNC machining cost-reduction process.

- Refine The Design of The Part: If you have a perfect design for the CNC machining part, it can significantly reduce machining costs.

- Right Tooling Reduces The Cost: Generally, traditional machining centers have manual tooling which increases the cost of the metal part. Find the best CNC machining company near you with the latest CNC machining equipment.

We can accommodate the prototyping and production of large machined parts, plastic or metal. Our maximum CNC machining build envelope is 2000 mm x 1500 mm x 300 mm — suitable even for large-scale furniture and architectural components.

If you want to start CNC machining parts production with Want.net, the process is quite convenient. Get in touch with us by clicking the Instant Quote button.

We follow the highest standards for manufacturing custom CNC machined parts. Since we have the latest CNC milling and turning equipment, you can drop your order in both small and bulk quantities.

Yes, we provide 5 Axis CNC machining solutions for metal parts with complex geometry and high precision standards. We offer our services for a range of materials with precise tolerances, curved surfaces, and fine detailing. Additionally, we provide post-processing services like plating, powder coating, and anodizing.

In a traditional machining shop, accuracy and precision are the biggest problems. Similarly, they follow traditional tooling methods which lack precision. Want.net ensures the highest manufacturing standards and has the industry’s leading CNC machining equipment along with expert operators.

Down to 0.001mm.

Put Your Machined Parts into Production Today!

You’re one-step away from the most affordable CNC machining service. Fill the form beside and we will get back to you within 24 hours.

GET QUICK QUOTE

- All uploads are secure and confidential