Advanced CNC Milling Services from WANT.NET

With our online custom machining service, you can order custom parts or prototypes with just a few clicks. Milling: As an essential machining technique for parts, we offer powerful CNC Milling equipment and excellent engineers to provide you with reliable and advanced technical support! All products are ISO 9001:2015, ISO 13485, and AS9100D certified or registered under ITAR.

- Free Quote and DfM

- Fast Lead Time

- Pay After Delivery

Home » CNC Machining » CNC Milling

WANT.NET: The Most Reliable And Advanced Milling Services

We provide reliable and advanced milling services for custom parts.Our CNC milling services for custom machined parts include the production of high-precision metal and plastic parts in a variety of sizes and forms using materials such as aluminum, stainless steel, brass, and plastics. We have state-of-the-art 3-, 4-and 5-axis CNC milling machines which deliver excellent results in producing parts with tight tolerances and complex shapes. Get a free CNC milling quote online now.

In addition, we offer small batch CNC machining which is perfect for custom CNC machined parts. Furthermore, you can ask for an online quote for prototype machining, and high-volume production runs.

High-Precision and High-Quality CNC Milling Services

Not only does our own factory have a wide range of advanced milling equipment and skilled engineers, but we also collaborate with hundreds of custom part manufacturers who possess similar advanced CNC milling equipment and excellent engineers. Our factory and these partner factories rely on cutting-edge equipment, skilled engineers, and advanced management processes to complete milling operations that meet all precision requirements, ensuring that customer specifications are fully satisfied.

Additionally, WANT.NET takes full responsibility for quality inspection. Before any part leaves our facility, our quality control center conducts a thorough inspection to ensure that only parts meeting customer specifications are delivered.

Our system continuously learns from production to delivery data. This data helps us improve and optimize processes to meet each customer’s needs, whether they require a small batch of rapid prototypes or tens of thousands of parts.

CNC Milling Service Precision and Complexity

Our CNC milling capabilities achieve a tolerance of ±0.01mm, ideal for manufacturing high-precision parts such as medical device components and aerospace parts. We excel at machining complex geometries, including multi-angled features and deep cavities. For batch production, our equipment ensures dimensional consistency, keeping tolerances well within design specifications.

Below is a detailed and credible data table showcasing the precision and capabilities of your CNC Milling services. The table includes various machining project types with their respective machining parameters, designed to highlight your technical strengths in a clear and professional manner.

| Machining Project | Max Machining Size | Tolerance Range | Minimum Feature Size | Surface Roughness | Applicable Materials | Max Cutting Depth |

| High-Precision Mold Parts | 500mm x 400mm x 300mm | ±0.01mm | 0.1mm | Ra 0.4μm | Tool Steel (H13), Aluminum (6061) | 50mm |

| Complex Surface Machining | 450mm x 350mm x 250mm | ±0.015mm | 0.2mm | Ra 0.6μm | Titanium Alloy (Ti-6Al-4V), Stainless Steel | 40mm |

| Thin-Wall Parts Machining | 400mm x 300mm x 200mm | ±0.01mm | Wall Thickness 0.5mm | Ra 0.5μm | Aluminum (7075), Engineering Plastics (POM) | 30mm |

| Deep Cavity Parts Machining | 300mm x 250mm x 150mm | ±0.02mm | 0.5mm | Ra 0.8μm | Stainless Steel (316), Brass | 100mm |

| Batch Parts Production | 600mm x 400mm x 300mm | ±0.02mm | 0.3mm | Ra 0.6μm | Carbon Steel, Aluminum | 40mm |

| Micro Parts Machining | 150mm x 100mm x 50mm | ±0.005mm | 0.05mm | Ra 0.3μm | Tungsten Steel, Engineering Plastics (PEEK) | 10mm |

Table Explanation

1. Machining Project:

o Includes high-precision mold parts, complex surfaces, thin-wall parts, deep cavity parts, batch production parts, and micro parts, covering a wide range of applications.

2. Max Machining Size:

o Demonstrates the maximum size of workpieces that can be handled for each type, showcasing the capability to process large-scale components.

3. Tolerance Range:

o Indicates the achievable tolerance range during machining, highlighting your expertise in high-precision manufacturing.

4. Minimum Feature Size:

o Shows the smallest features that can be machined (e.g., tiny holes or thin walls), reflecting proficiency in fine-detail machining.

5. Surface Roughness:

o Surface roughness is a critical metric of machining quality, showing your ability to deliver smooth, high-quality finishes.

6. Applicable Materials:

o Lists a variety of materials, from standard metals (aluminum, stainless steel) to difficult-to-machine materials (titanium alloys, tool steel) and engineering plastics.

7. Max Cutting Depth:

o Highlights the ability to handle deep cavity parts, showcasing expertise in machining complex structural components.

Does the milling process affect the price?

Customers can use Want.net online CNC machining quotation system for instant price queries. We have a comprehensive mechanism that caters to your requirement and gives professional advice. In addition, our prices for custom CNC machining parts are quite attractive.

For orders requiring milling, our pricing remains competitive compared to others in the industry. This is because our advanced milling machine, reasonable labor costs, and production capacity give us the ability to offer you the most competitive prices.

If you want to get an estimated quote to order metal or plastic customized parts online, send your requirement to our given email address.

Equipment and Technology

We are equipped with world-class CNC milling machines:

• DMG MORI DMU 50: Supports 5-axis machining, with a table size of 500mm x 400mm, ideal for high-precision complex parts and curved surfaces.

• Haas VF-4: Offers a machining range of 1270mm x 508mm x 635mm, suitable for large workpieces with high efficiency.

• Makino PS95: Known for its high-speed spindle and precise tool path planning, perfect for high-precision molds and batch parts.

Our equipment features automatic tool changers (ATC) and machine monitoring software, optimizing machining efficiency and minimizing downtime.

Material Capabilities

The Industries We Serve

Surface Finishing and Post-Processing

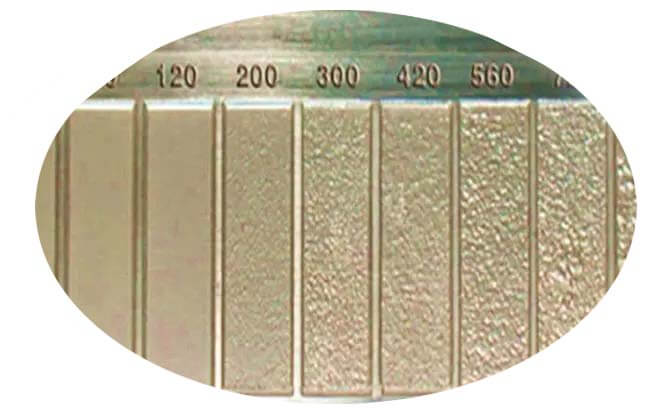

We specialize in high-quality surface finishes, achieving exceptional smoothness and precision.

• Surface Finish: Our milling equipment achieves a surface roughness of Ra 0.4μm, suitable for products requiring high surface quality.

• Post-Processing Support: We provide additional services such as anodizing, electroplating, and sandblasting, offering clients a one-stop manufacturing solution.

Why Choose Our Online Custom CNC Machining Service

CNC machining is necessary for custom-machined components because it delivers accuracy and consistency that other methods, such as manual machining, cannot achieve.

CNC machining enables the accurate manufacturing of items to exact specifications, with dependable repeatability and accuracy. Higher production rates are also made possible since machines are capable of doing manual machining tasks more quickly and correctly.

Additionally, complex parts can be produced using CNC machining, which is not possible with traditional machining.

What is CNC Milling: Types, Processes & Benefits

What is CNC Milling? How Does it Differ from Traditional Milling? Milling is one of the most versatile machining processes used to manufacture parts with

Get a Quick Quote Now

You’re 1-step away from our incredible quote of CNC milling service.

- All uploads are secure and confidential