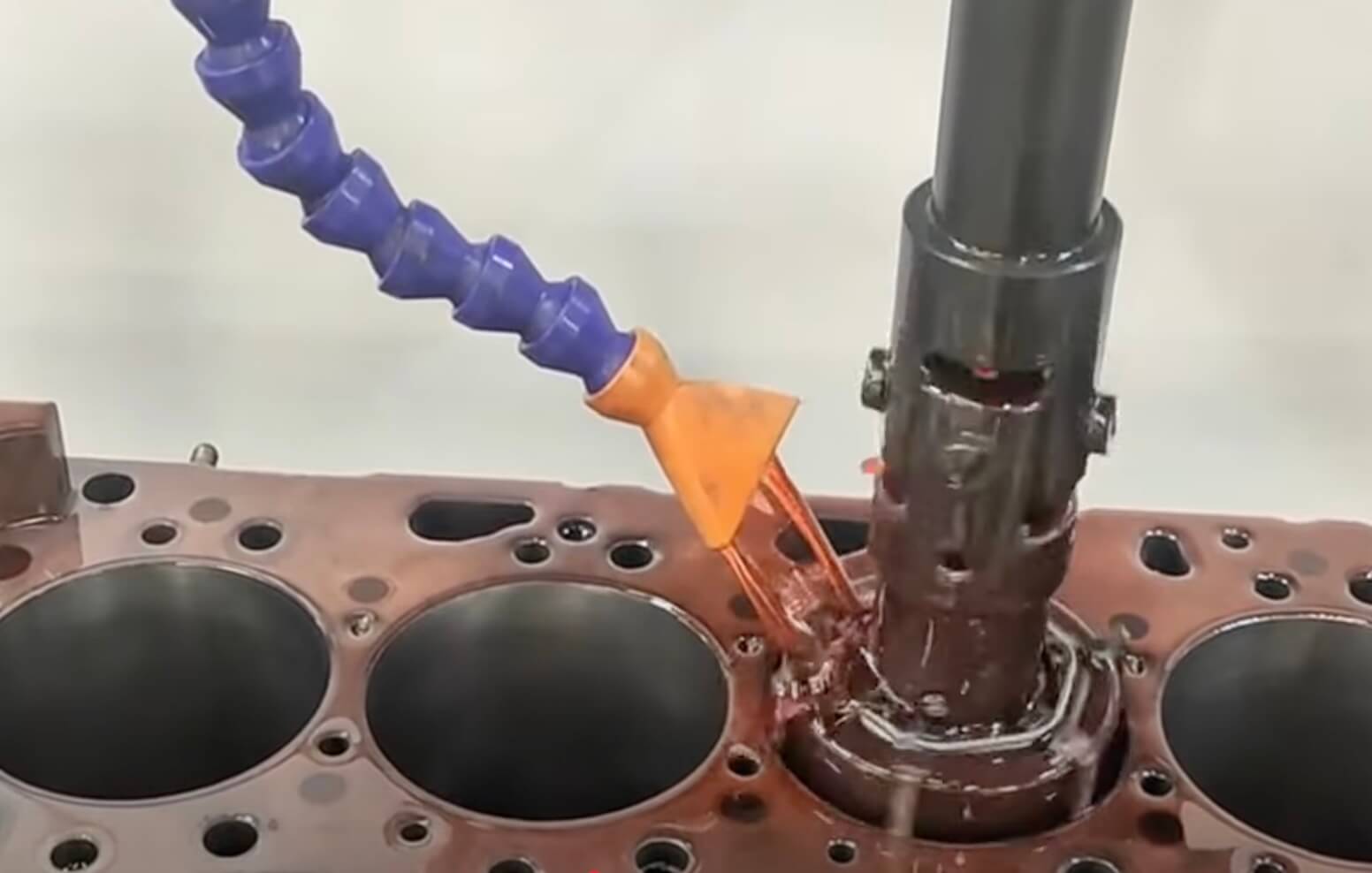

I’m sharing my process for CNC milling a slot to fit a toggle switch in this video. Using Fusion 360, I design a slot to accommodate the switch. I program the toolpath, setting up my CNC lathe with a 2 mm flat-end mill. Adjusting feeds to 0.1 mm/rev and using coolant, I mill a slot in an workpiece, ensuring a smooth finish. The machining takes patience to achieve the exact fit. Once complete, I install the switch, and it snaps in perfectly, ready for use. This video walks through my steps for CNC milling a slot, offering tips for engineers and machinists tackling similar projects. Follow along to see how I turn a design into a functional part!