About Want.Net

Welcome to Want.Net, your trusted partner for custom manufacturing in China. With over 13 years of experience, we have grown into a leading manufacturer specializing in CNC machining, sheet metal fabrication, and 3D printing services. Unlike traditional platforms, we take pride in being the direct manufacturer behind our exceptional products.

To meet the rapidly growing demands of global customers and strictly fulfill their requirements for delivery time and quality, starting in 2025, we have expanded the scale of our own factories, now exceeding 10,000 square meters. Leveraging our in-house production capabilities, extensive manufacturing data, and expert team, we have added and upgraded production equipment, optimized every aspect of the manufacturing process, significantly boosting efficiency while ensuring product quality, thus shortening delivery times.

Quality is the core of Want.Net and the foundation of our reputation. Since our establishment, we have prioritized the development of our inspection center. Today, we operate the largest inspection center in China, located in Shenzhen. Every part or prototype is thoroughly inspected by our highly trained engineers. This is why we maintain a repeat purchase rate of over 90%.

Factory and Equipment

Our manufacturing facilities are located in Shenzhen and Dongguan, China. It covers over 10,000 square meters, equipped with a well-balanced combination of mid-range and selected high-end machines. This setup ensures reliable quality, efficient turnaround, and cost-effective services for global clients.

CNC Machining Equipment

We currently operate dozens of vertical and horizontal machining centers, along with more than ten CNC lathes., primarily for precision parts in aluminum, stainless steel, carbon steel, and plastics.

VDL-850 Vertical Machining Center – Shenyang Machine Tool (China)

VMC650 Machining Center – Dalian DMTG (China)

Robodrill α-D21MiB – FANUC (Japan), for high-speed, small-part machining

CMX 50U – DMG MORI (Germany), 5-axis machining for complex geometry

Sheet Metal Fabrication

For sheet metal work, we handle cutting, bending, and punching processes in-house. Materials from 0.5mm to 20mm thick are processed daily.

HL-3015 Fiber Laser Cutter – Han’s Laser (China)

P3-1530 Fiber Laser – Bodor (China)

PBH 110/3100 CNC Press Brake – Yawei (China)

HG-1003 CNC Press Brake – Amada (Japan)

Welding & Automation

We support both manual and robotic welding, ensuring strong, consistent joints for metal assemblies.

NB-500 MIG Welding Stations – NBC (China)

TM-1400 Robotic Welding Arm – Panasonic (Japan)

Mold Making & EDM

Our in-house tooling section allows us to manufacture fixtures, jigs, and stamping dies efficiently.

BM350 Wire EDM – Baoma, Suzhou (China)

AD35L Sinker EDM – Sodick (Japan)

GSK-Controlled Toolroom Mills – GSK (China)

Quality Inspection

We take quality seriously, with every part verified using industry-standard tools and documented inspection protocols.

Crysta-Plus M443 CMM – Mitutoyo (Japan)

UMA324 CMM – UNIMETRO (China)

iReal 2E 3D Scanner – Scantech (China)

HT-6510A Hardness Tester – Huatec (China)

UTM 100kN Tensile Machine – Jinan Wance (China)

We also maintain an ERP-driven production system, and our inspection data is connected to SPC software, allowing for full process traceability and real-time quality tracking. All operations are ISO 9001 certified.

Thanks to this balanced setup, we’re able to handle both 1-piece prototypes and large-batch runs up to 5,000 pcs, all while keeping tolerances within ±0.01mm.

Team Behind Want.Net

Our workforce of 300+ dedicated professionals covers R&D, CNC machining, design, manufacturing, quality control, and logistics, supported by 20+ full-time quality inspectors monitoring the entire production cycle. Here is a closer look at our key teams:

R&D and Engineering Team

Proficient in software like SolidWorks, AutoCAD, and Siemens NX, they continuously improve product design and optimize manufacturing processes.CNC Machining Team

Comprising experienced programmers, setup technicians, and machine operators, this team manages everything from toolpath generation to final machining. Their expertise enables flexible handling of complex parts, ensuring high precision and efficiency.Production Management Team

Utilizes ERP systems and barcode tracking to coordinate multiple production lines, guaranteeing on-time and high-quality deliveries for every project.Quality Control Team

Conducts rigorous incoming, in-process, and final inspections using advanced equipment such as CMMs and laser scanners. They ensure each product meets both international standards and client-specific requirements.Customer Service Team

Offers multi-lingual support (English, German, Japanese, etc.), promptly responding to engineering changes or order updates. They provide technical consultation and after-sales service to maintain a smooth global collaboration.

We uphold the principle of “Continuous Improvement and Excellence,” with customer satisfaction as our top priority.

Unmatched Manufacturing Power

Green Manufacturing, Sustainable Future: Our Commitment to the Environment

As a global custom manufacturing service provider specializing in CNC Machining, 3D Printing, and Sheet Metal Fabrication, Want.net takes pride not only in product quality but also in environmental responsibility. Our factory is built on the belief that innovation and sustainability must go hand in hand.

Energy-Efficient Equipment and Clean Production

We actively adopt green technologies in our workshops:

CNC Machines: We use high-efficiency models like the HAAS VF-2SS and Mazak VCN-530C, which feature energy-saving standby modes and efficient servo drives.

3D Printers: Our Stratasys F370 and Raise3D Pro3 Plus printers are optimized for low power consumption and minimal material waste.

Smart Systems: We employ an ABB Ability™ Energy Management System to monitor and optimize energy use across workshops, reducing overall energy consumption by 15–18% annually.

Coolant Management: We use Blaser Swisslube biodegradable coolants that reduce toxic emissions and extend the service life of cutting fluids by over 30%.

Material Optimization and Waste Management

Every gram of material matters in sustainable manufacturing:

Advanced Nesting Software like SigmaNEST is used to plan sheet metal layouts, reducing waste by up to 12%per production run.

Scrap Sorting: Aluminum, copper, and stainless steel scraps are collected separately and sent to certified recycling plants weekly. On average, we recycle 2.4 tons of metal waste/month.

Plastic Filament Recycling: In 3D printing, leftover PLA and ABS materials are collected, shredded, and reused internally for non-critical prototypes using Filabot Reclaimer Systems.

Chemical Waste Control: All liquid waste is processed through Zhejiang Yuanli Environmental Equipment Co.’s filtration unit, ensuring compliance with China’s GB 8978 wastewater discharge standards.

Reducing Carbon Emissions and Renewable Energy

We reduce our carbon footprint through actionable steps:

Solar Panels: Our factory roof hosts a 128 kW solar PV system, which supplies roughly 22% of our total electricity needs.

Eco-Friendly Packaging: We use honeycomb kraft paper and recyclable corrugated boxes, reducing plastic usage by 50% compared to 2020 levels.

Green Logistics: Collaboration with DHL GoGreen ensures low-emission transport options for overseas clients.

Paperless Workflow: Over 90% of our internal processes (quotations, order tracking, inspection reports) are now fully digitalized.

Environmental Certifications and Regulatory Compliance

Our operations align with the highest standards:

All raw materials meet RoHS and REACH compliance standards.

Air and wastewater discharges are tested quarterly by third-party agencies like SGS, with all results publicly available on our sustainability portal.

Empowering Employees & Building a Green Culture

Sustainability is a shared mission:

New employees receive mandatory green manufacturing training during onboarding.

Our “Green Idea Fund” encourages staff to submit environmental suggestions—over 50 implemented in the past year.

Monthly workshops and an annual “Green Factory Day” foster environmental awareness.

Voluntary participation in local tree-planting projects has led to the planting of numerous saplings since 2022.

Partnering with Clients for a Better Planet

Working with Want.net means more than just reliable manufacturing—it means being part of a responsible global supply chain.

We invite you to contact us for a virtual or in-person factory tour to see our environmental practices in action. Let’s build better, greener, together.

We believe that sustainability is no longer optional—it’s a shared responsibility. That’s why we continuously invest in energy-efficient technology, responsible material sourcing, and waste reduction systems across all stages of production.

Let’s turn your custom manufacturing needs into a greener solution—for your business, and for the planet.

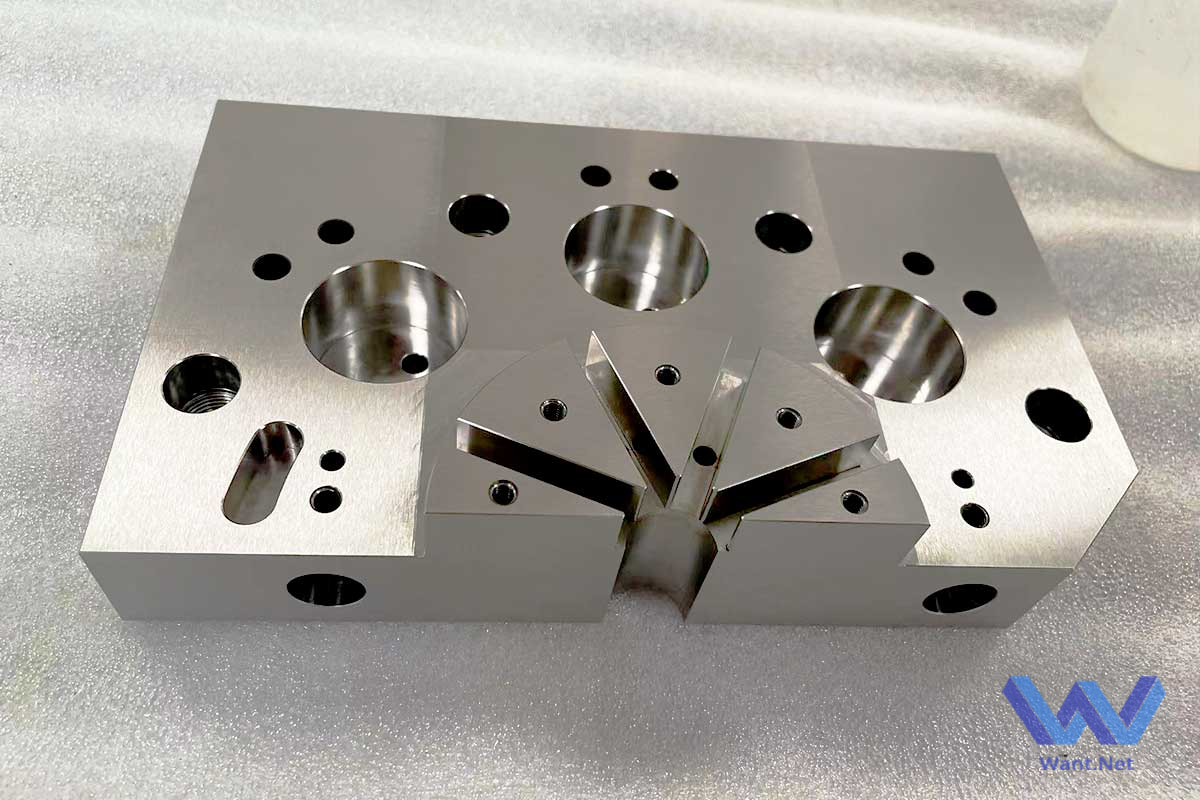

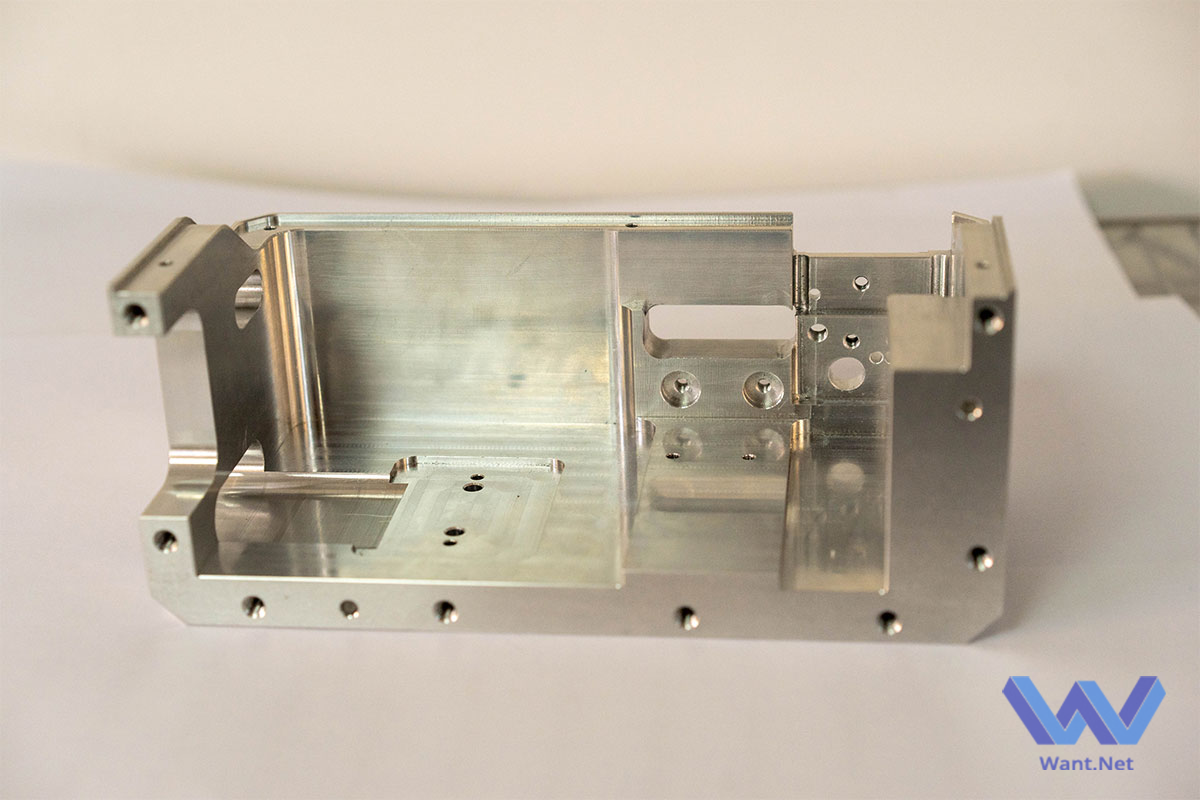

Machined Parts Gallery

Our Service

CNC Machining Services

Precision CNC machining services including CNC turning, milling, drilling and more.

Injection Molding Services

Discover endless options of our custom injection molding service. No MOQ and tight tolerance.

Sheet Metal Fabrication

Check out our online sheet metal cutting and bending service. Upload your file and get a free quote today.

Custom 3D Printing Services

Get a rapid high-quality prototyping or final printed parts with our online 3D printing service.

CNC Machining Services

Precision CNC machining services including CNC turning, milling, drilling and more.

Sheet Metal Fabrication

Check out our online sheet metal cutting and bending service. Upload your file and get a free quote today.

Custom 3D Printing Services

Get a rapid high-quality prototyping or final printed parts with our online 3D printing service.

Our Milestones

-

2010 - Establishment of First Self-Owned Factory in Shenzhen

We have established our first factory in Shenzhen to provide CNC machining services for milling and lathe parts to global customers.

-

2012 - Five-Fold Increase in Production Scale of Self-Owned Factories

The self-owned manufacturing capacity has increased by fivefold, allowing us to offer comprehensive CNC machining services to clients worldwide, covering all CNC technologies

-

2014 - Double Production Scale of Self-Owned Factories Compared to 2012

Want.Net improved its production and service capabilities for CNC machine tools, earning recognition from global customers. The number of customers served increased by 300%, exceeding 300.

-

2016 - Establishment of Production Network

Want.Net established a production network with other local manufacturing suppliers to jointly serve global customers. The network strictly managed production in accordance with the requirements of Want.Net's self-owned factories.

-

2017 - Expansion of Joint Quality Inspection Center and Production Scale

The "Joint Quality Inspection Center" expanded to more than 500 square meters, meeting the rapid inspection needs of more delivered products. Want.Net's self-owned factory expanded its production to the field of sheet metal manufacturing while continuing to strengthen the production capacity of CNC machine tools.

-

2019 - Further Expansion of Production Network and Quality Inspection Level

Want.Net expanded the number of cooperative suppliers to 40, and the "joint quality inspection center" expanded to more than 1,000 square meters to improve the quality inspection level. The production scale of Want.Net's self-owned factory continued to expand, and the production technology of CNC improved, enabling large-scale production of complex production processes.

-

2022 - Comprehensive Development of Internet Channels

Want.Net integrated manufacturing with the internet, expanding the number of cooperative suppliers to 100 and linking global customers and China's best manufacturing suppliers. This integration enabled Want.Net to better export its production capacity and supporting services to global customers and promote the global development of on-demand manufacturing.

-

2025-Expanding Our Own Factories for Your Custom Parts

To ensure we can meet the rapidly growing demands of global customers while strictly adhering to their requirements for delivery time and quality, starting in 2025, we have expanded the scale of our own factories. Ultimately, we guarantee that 100% of products are delivered directly from our own factories, ensuring complete control over quality and timelines.

How We Assure The Quality

Our manufacturing services are backed by advance inspection equipments. Take a closer look at our quality inspection process.

Get A Free Quote Today!

Contact Want.Net today for on-demand manufacturing that exceeds your expectations. Experience the difference in quality and customer service!