Introduction to Innovations in Flange Fabrication with Chinese CNC Techniques

The integration of CNC technology into flange fabrication marks a significant advancement in the manufacturing sector, particularly in China. This adoption has set new benchmarks for precision and efficiency in producing critical components for piping systems. The evolution from basic machining to advanced CNC applications highlights China’s commitment to technological innovation and manufacturing excellence.Now, Chinese companies can also provide online cnc machining services.

CNC Technology Overview: From Basics to Advanced Applications

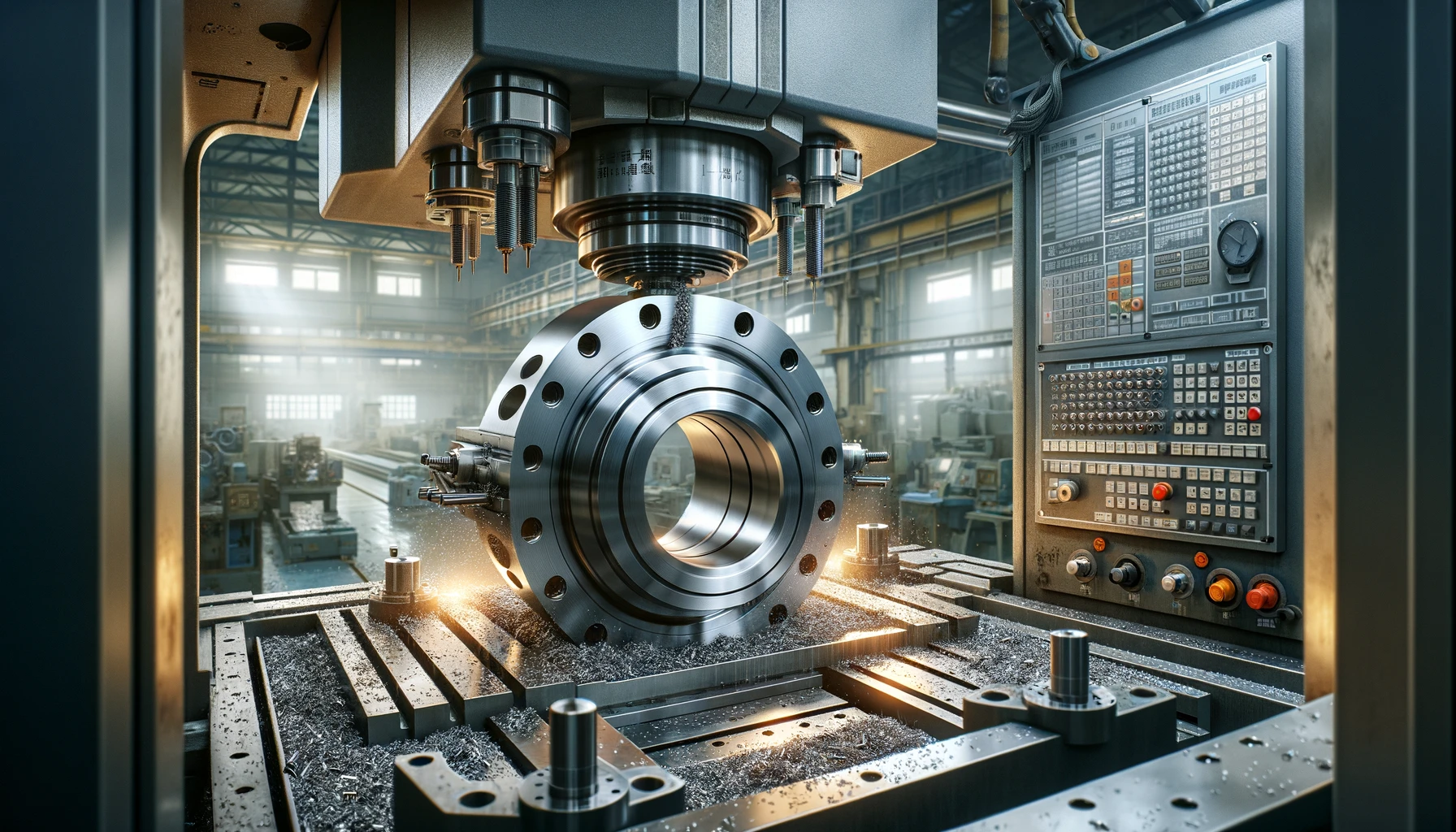

CNC technology serves as the backbone of modern manufacturing, offering unparalleled precision and automation. It involves computer-controlled machining tools that fabricate components with high accuracy. In flange fabrication, CNC machines play a crucial role in drilling, milling, and turning processes, ensuring each flange meets stringent specifications. The mechanics of CNC machines, especially in creating complex flange geometries with impeccable precision, are central to the efficiency and reliability of the final products.

China Online CNC Machining Service

Key Challenges in Flange Fabrication and CNC Technological Solutions

Flange manufacturing encounters several challenges, from material wastage to intricate designs and maintaining tight tolerances. One significant hurdle is the production of large-diameter flanges for the oil and gas industry, where precision is paramount. For example, creating a 48-inch diameter flange with precise bolt holes alignment using traditional methods can be time-consuming and prone to errors.

CNC technology offers a solution through advanced programming that allows for precise control over the machining process. A specific case involves using a high-precision CNC milling machine equipped with a titanium carbide cutting tool, capable of maintaining a tolerance of +/- 0.005 inches, even on large-diameter flanges. This level of precision ensures that each flange perfectly matches the specifications, reducing the need for rework and material wastage.

Another challenge is the fabrication of custom flanges with unique geometries for specialized applications, such as flanges with multiple grooves and notches for aerospace applications. Traditional machining methods struggle to achieve the required precision and often result in high scrap rates. By utilizing a 5-axis CNC machining center, manufacturers can produce complex shapes with high precision, following a 3D model provided by the client. This approach not only ensures accuracy but also significantly reduces production time and costs.

Case Study: A Success Story of CNC Flange Manufacturing in China

A notable success story in the realm of CNC flange manufacturing in China involves a leading manufacturer specializing in high-pressure flanges for the petrochemical industry. Faced with the challenge of producing a series of custom flanges for a new high-pressure reactor, the manufacturer leveraged advanced CNC turning and milling centers, capable of handling Inconel, a superalloy known for its extreme pressure and heat resistance.

The project required the production of 100 custom flanges, each with a unique design to accommodate various connections and pressure ratings within the reactor. Using a state-of-the-art CNC machining center, the company programmed the precise dimensions and tolerances for each flange, achieving a production accuracy of +/- 0.001 inches. The use of automated tool changers and multi-axis machining capabilities allowed for the efficient fabrication of complex geometries, including deep grooves and precise threading for leak-proof sealing.

This case not only demonstrated the technical capabilities of Chinese CNC technology in producing high-quality, custom flanges but also highlighted the efficiency gains. The project was completed in half the time traditionally required, with a significant reduction in material waste and a 100% pass rate in quality control tests, setting a new standard in flange manufacturing for high-pressure applications.

Future Trends and Innovations in CNC Flange Manufacturing

The future of flange manufacturing is poised for further transformation with continuous advancements in CNC technology. Emerging trends such as automation, AI integration, and sustainable manufacturing are set to redefine the standards of flange production. These speculative future technologies hold the potential to further enhance the efficiency and sustainability of flange manufacturing processes, promising a new era of innovation and excellence in the industry.

Related Posts

- Flange Production Mastery with China's CNC Services

Exploring the Landscape of Flange Production in China China cnc machining service is developing very rapidly and have become an important force in global CNC processing services. Especially in the…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Optimizing Tool Paths: Advanced Techniques for Efficient CNC Titanium Machining in China

Introduction to CNC Titanium Machining in China In the dynamic landscape of global manufacturing, China stands out, especially in CNC (Computer Numerical Control) machining. Titanium, prized for its strength and…