At present, the global aerospace industry market value has increased by 278.43 billion, an increase of 6.6% compared to 2022. The ultra-high value proves that innovation in the aerospace industry is very mature, and manufacturing practices and technologies are at the forefront.

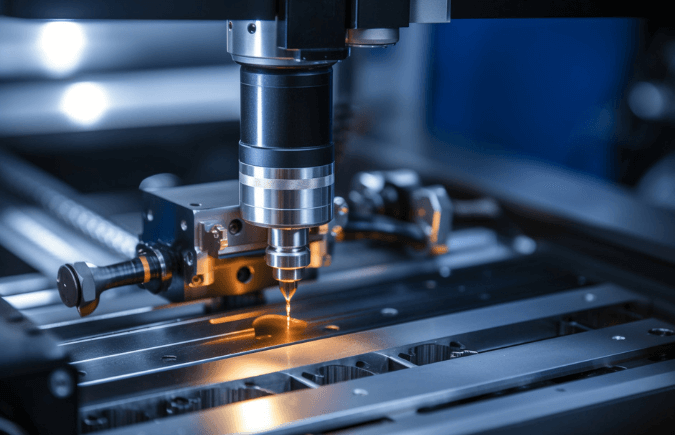

So, If somebody says: Aerospace CNC machining is now the most critical component of the industry. It is not without reason. For the parts needed for aerospace, one of the most important indicators is of course safety. Therefore, CNC machining, which can provide extremely high-precision production methods, has become the most suitable manufacturing process for this industry.

Why does the aerospace industry use CNC Machining?

At the beginning of this article, We already said that CNC machining can provide the aerospace industry with the precision it needs. It is one of the main reasons why CNC machining can be used in this industry. But at the same time, you should be very aware that there is definitely more than one processing technology used in the aerospace industry, including CNC. Therefore, you will encounter a question: Why can CNC machining become an important manufacturing process in the aerospace industry? We list the following 3 reasons for you:

- 1. For lightweight components that are not critical to system functionality, 3D printing is often used. But for engine parts and other critical components, the only way to achieve the necessary tolerances is to use CNC machining. This is because any errors in these parts may cause fatal injuries.

- 2. For some irregular parts, CNC machining is safer, more effective, higher quality, and lower cost than other processing methods.

- 3. CNC machining methods are very common, and their applications are as diverse as the parts they manufacture.

How CNC machining is used in the aerospace industry?

As we all know, CNC machining has many applications in different industries. A plane has millions of parts. Therefore, there are many manufacturing processes to complete the manufacturing of an aircraft. It contains advanced technologies such as sheet metal manufacturing and injection molding to aerospace CNC machining and 3D printing.

Aerospace CNC machining companies combine sophisticated design and engineering software with state-of-the-art inspection processes. This can ensure the safety and ultimate high quality of CNC machining parts in the aviation industry. In addition to playing a vital role in the production of end-use parts, it also plays an important role in research and development. This role allows aerospace companies to quickly change part designs according to the development of times and complete necessary testing.

In aerospace CNC machining, choosing the right material is also a necessary process. Here we will introduce to you the types of materials commonly used in aerospace CNC machining.

Lightweight metal

CNC machined materials used by aerospace companies have two key properties – strength and quality. Although metals such as steel are recognized as very strong metals, they are not an ideal choice when it comes to selecting materials for CNC-machined parts in aerospace. This is because they are very heavy, making the aircraft less fuel efficient. Therefore, most aerospace companies choose lighter metals such as titanium and aluminum alloys. These lightweight metals are not only lightweight but also easy to process.

High-performance plastics

In the manufacture of aircraft, lightweight metals are mostly used in external components. But for most internal components, polymer materials are typically used. These materials are typically much lighter and stronger than metal and comply with aerospace flame retardant regulations.

Extra Tips: 8 important things about CNC machining aerospace parts

At this point, you have to understand why aerospace CNC machining is so common and important. To better understand CNC machining aerospace parts, we have compiled a few tips below.

Importance of lightweight metals to aircraft performance: Lightweight metals help improve an aircraft’s fuel economy and overall efficiency. And easy to process.

Importance of CNC prototyping for aerospace R&D: CNC machines rely on 3D CAD models and computer instructions to create parts. This allows aerospace engineers to quickly create prototype designs and complete necessary testing.

5-axis CNC machines help manufacture complex designs: Aerospace part designs are increasingly complex and require ultra-high precision, which means extremely tight tolerances. The 5-axis CNC machine can achieve a range of angles that 3-axis and 4-axis machines cannot reach, and create more complex part designs.

Artificial Intelligence combined with CNC machinery to power the future of part production: Modern CNC machine tools used in the aerospace industry are now equipped with artificial intelligence (AI) and machine learning software. This allows the aerospace industry to more accurately design the parts it needs to manufacture itself.

CNC machining reduces aerospace manufacturing costs: CNC machining has always been welcomed by various industries for simplifying the process without affecting the quality of parts. Therefore, in the aerospace industry, the precision that CNC machining can bring not only improves production efficiency but also shortens the production cycle and saves expenses and costs.

The importance of quality control for aerospace CNC machining: dimensional errors in every small part of an aircraft may lead to huge dangers. Therefore, in aerospace CNC machining, quality control, and regular maintenance are necessary means to ensure safe performance.

Conclusion

At this point, you will find that the use of CNC machining in the aerospace industry not only relies on the accuracy of CNC machining but also the widespread use and low cost of CNC machining, as well as the availability of materials. With CNC machining, parts for the aerospace industry can be achieved to extreme tolerances to the standards they require. Here, Want.net can be said to be an expert in this field, advanced technology machines, and professional team equipment all demonstrate the strength of Want.net.

Related Posts

- Ensuring Efficient CNC Machining in the Aerospace Industry

The aerospace industry represents the pinnacle of human thought and engineering, with its focus on designing and producing gigantic flying machines such as rockets, airplanes, and jets. However, the complexity…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- CNC Machining in Aerospace: Optimizing for Lightness and Strength

Introduction to CNC Machining in Aerospace CNC (Computer Numerical Control) machining stands as a cornerstone in the aerospace industry, enabling the precise fabrication of components. This technology is pivotal for…