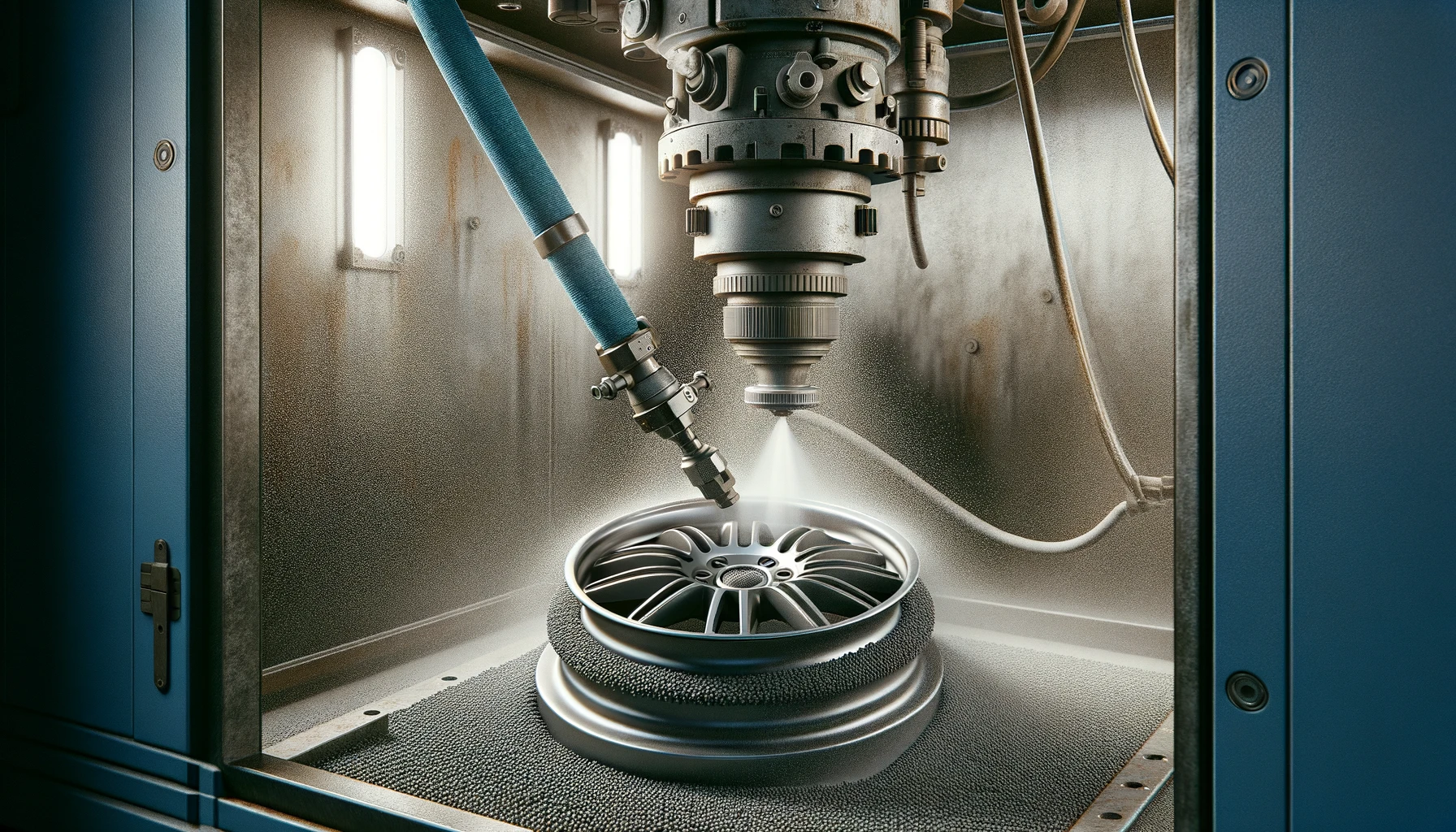

Introduction to Bead Blasting in Wheel Hub Finishing

Bead blasting has emerged as a pivotal technique in the realm of surface finishing, particularly in the automotive sector where it is applied to enhance the surface quality of critical components like wheel hubs. This intricate process involves the propulsion of fine beads, typically made of glass or ceramic, at high velocities towards the target surface. The primary aim is to obliterate surface impurities, thereby endowing the wheel hubs with a uniformly matte and aesthetically pleasing finish. Moreover, this technique significantly bolsters the corrosion resistance of the hubs, an attribute of paramount importance in vehicular components. The choice of bead material, coupled with the control over blasting parameters, plays a crucial role in dictating the quality and consistency of the finish achieved. This introduction sets the stage for a deeper exploration of the bead blasting process, highlighting its application, challenges, and the nuances involved in achieving optimal results in the context of China’s burgeoning CNC machining industry.

The Importance of Surface Preparation in CNC Machining

In the intricate dance of CNC machining, surface preparation stands as a critical prelude, setting the tone for the finishing symphony that follows. This preparatory phase is not merely a formality but a foundational step that ensures the ensuing bead blasting process can be executed with precision, yielding finishes that meet the stringent aesthetic and functional standards demanded by the industry. The process encompasses a thorough cleansing and degreasing of the metal surface, sometimes accompanied by a mild etching to augment the surface’s receptivity to bead blasting. This meticulous preparation helps in mitigating potential defects and ensures the bead blasting process can be conducted in an optimal manner, thereby ensuring that the final finish on the wheel hubs is devoid of imperfections and aligns seamlessly with the desired specifications.

Key Challenges in Bead Blasting for Wheel Hubs

Navigating the bead blasting landscape, especially when dealing with components as critical as wheel hubs, presents a unique set of challenges. The quest for a consistent surface finish is fraught with hurdles, as variations in material properties and the dynamic conditions of the blasting process can lead to discrepancies in the end result. The peril of over-blasting looms large, threatening to erode the surface and compromise the structural integrity of the wheel hubs. Furthermore, the process is inherently messy, generating copious amounts of dust and debris that not only pose significant health risks but can also mar the quality of the finish. Addressing these challenges demands a deep understanding of the blasting process, a meticulous control over the blasting parameters, and a commitment to maintaining a clean and safe working environment.

Case Example: The journey of a prominent automotive manufacturer to refine the quality of their alloy wheel hubs is a testament to the complexities inherent in the bead blasting process. Despite adhering to a stringent blasting protocol, the company was plagued by inconsistencies in the finish of their wheel hubs, leading to unacceptable rejection rates. A thorough investigation pinpointed the root cause to be fluctuations in air pressure and the quality of beads used across different blasting stations. The resolution lay in the implementation of a centralized monitoring system, coupled with the standardization of bead specifications across the board. This strategic intervention transformed the blasting process, ushering in an era of uniform finishes and significantly reducing wastage.

Selecting the Right Beads for Optimal Finish

The choice of beads in the bead blasting process is not one to be taken lightly. It is a decision that holds the power to influence the texture, appearance, and overall quality of the finish on wheel hubs. The table below serves as a guide, delineating the characteristics of various bead types and their consequent impact on the surface finish:

| Bead Type | Material | Size (Microns) | Surface Finish Result |

|---|---|---|---|

| Type A | Glass | 100-200 | Smooth, matte finish |

| Type B | Ceramic | 150-250 | Slightly rougher, more textured finish |

| Type C | Steel | 200-300 | Bright, peened finish |

| Type D | Plastic | 50-100 | Very gentle, minimal abrasion |

| Type E | Walnut Shell | 200-400 | Eco-friendly, soft finish |

| Type F | Aluminum Oxide | 100-300 | Aggressive, for heavy-duty cleaning |

| Type G | Silicon Carbide | 50-200 | Ultra-fine, precision finish |

| Type H | Stainless Steel | 300-500 | Durable, high-luster finish |

Each bead type brings its own set of attributes to the table, influencing not just the aesthetic appeal but also the functional characteristics of the wheel hubs. The art of selecting the right bead involves a delicate balance between the desired finish and the material properties of the hub, ensuring that the chosen beads complement and enhance the intrinsic qualities of the metal.

Case Example: An innovative approach by an aftermarket wheel hub manufacturer highlights the significance of bead selection. In their quest to differentiate their products in a competitive market, they embarked on an experimental journey with various bead types. The breakthrough came with the strategic combination of Type B (Ceramic) beads for their durability and surface compatibility, and Type G (Silicon Carbide) beads for their ability to impart an ultra-fine, precision finish. This distinctive blend not only elevated the aesthetic appeal of their wheel hubs but also enhanced their resistance to wear and tear, setting a new standard in the industry.

Precision Control in CNC Machining for Bead Blasting

Precision in bead blasting, especially within the precise realm of CNC machining, necessitates an intricate ballet of parameters. Each element, from air pressure and bead flow rate to the nozzle’s distance from the target surface, plays a critical role in sculpting the final finish. Slight deviations in these parameters can lead to dramatic variations in the surface quality, underscoring the need for meticulous control and constant monitoring. The integration of advanced CNC technologies allows for unprecedented precision in controlling these variables, enabling operators to achieve consistent and high-quality finishes across a multitude of wheel hubs. This precision not only enhances the aesthetic appeal of the hubs but also contributes to their longevity and performance.

Ensuring Uniformity and Consistency in Finish

The pursuit of uniformity and consistency in the bead blasted finish of wheel hubs is a paramount concern in the automotive industry, where standards are exacting, and the margin for error is minimal. Achieving this level of consistency requires a harmonious symphony of calibrated equipment, uniform bead quality, and rigorous process controls. Regular maintenance and calibration of blasting equipment ensure that each wheel hub is subjected to the same conditions, thereby mitigating the risk of variability. Moreover, stringent quality control measures, encompassing both the beads and the blasting process, serve as the linchpin in upholding the high standards of finish required in the industry.

Overcoming Common Technical Difficulties in Bead Blasted Wheel Hubs

The realm of bead blasted wheel hubs is not without its technical adversities. Issues such as surface contamination, uneven finishes, and the rapid wear and tear of blasting equipment pose significant challenges to manufacturers. Tackling these difficulties demands a multifaceted strategy that includes the adoption of state-of-the-art maintenance practices for blasting equipment, stringent quality control protocols, and a relentless drive for process improvement. By addressing these challenges head-on, manufacturers can ensure the production of bead blasted wheel hubs that not only meet but exceed the rigorous demands of the automotive industry.

Case Example: The experience of a luxury car manufacturer sheds light on the intricate interplay of factors that can impact the quality of bead blasted wheel hubs. The discovery of premature corrosion on certain batches of hubs led to an exhaustive investigation, which revealed the inadvertent presence of silicone-based lubricants from the manufacturing process. These contaminants, though minute, were significantly impairing the bead blasting process, leading to subpar finishes and compromised durability. The introduction of an ultrasonic cleaning stage prior to bead blasting emerged as a game-changer, effectively eliminating the contaminants and significantly enhancing the corrosion resistance of the wheel hubs. This proactive measure not only resolved the immediate issue but also set a new standard in the manufacturing process, ensuring higher quality and reliability of the finished product.

Related Posts

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…