Introduction to Custom CNC Machining Solutions for Brass and Stainless Steel

Custom CNC (Computer Numerical Control) machining is a manufacturing process that involves programmed codes directing the movement of factory tools and machinery. The purpose of this automation is to efficiently produce intricate, high precision parts with maximum accuracy. This advanced method is particularly critical for materials such as brass and stainless steel, which require precise craftsmanship due to their hard-wearing nature. In inputting design instructions into computer software, custom CNC machines effortlessly convert raw material into well-defined products by executing complex cuts and shapes.

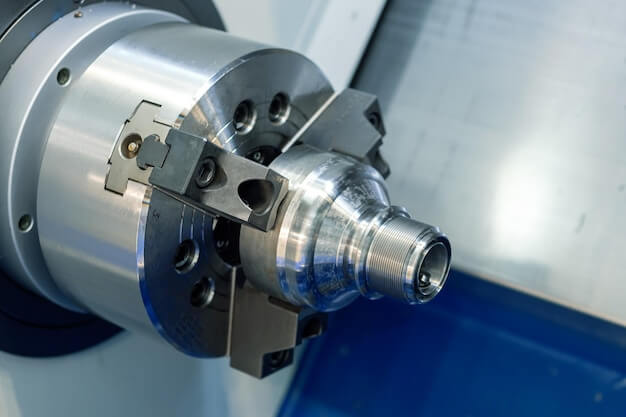

- The main components in a CNC machine include: Controller, Drive System, Spindle, Machine Bed, and Coolant supply tube. Each serves unique roles; the controller interprets instructions, the drive system regulates speed and placement, the spindle holds and rotates the workpiece, the machine bed provides support, and finally, the coolant supply tube keeps the machine and workpiece at optimal temperature during operation.

Each element works cohesively ensuring metric precision and efficiency throughout the production process.

Understanding Brass and Stainless Steel

In the field of custom CNC machining, two materials commonly employed are brass and stainless steel. These metals possess distinct properties that make them ideal for manufacturing. Brass, an alloy made primarily of copper and zinc, is valued for its high thermal conductivity, ease of machining, corrosion resistance, and aesthetic appeal. It’s often used in electrical components, gears, locks, valves, and musical instruments.

- Thermal Conductivity: This property allows a material to conduct heat which makes it well-suited for use in applications where temperature management is needed.

- Machinability: Brass can be easily cut into various shapes required for product design, lending itself to intricate accents or detailed mechanical parts.

- Corrosion Resistance: Brass has a strong ability to withstand corrosive elements making it ideal for outdoor use or exposure to harsh environments.

- Aesthetic Appeal: The distinctive yellow-gold color provides an attractive finish in products where aesthetics matter, such as home decor or accessories.

On the other hand, stainless steel offers impressive strength-to-weight ratio, exceptional corrosion resistance, and excellent formability – characteristics especially suited for industries like aerospace, automotive, medical, and food processing.

- Strength-to-Weight Ratio: Stainless steel is prized for providing substantial strength without adding significant weight, vital in sectors like aerospace where every gram matters.

- Corruption Resistance: Its non-reactiveness with many substances ensures durability under varied working conditions particularly in medical equipment and kitchen utensils.

- Formability: Despite its superior strength, stainless steel is easily moldable, increasing its application possibilities significantly.

The Need for Customized CNC Machining Solutions

In the manufacturing industry, customized solutions are increasingly demanded due to their intrinsic ability to address unique production specifications that standard tools and procedures often fail to meet. This is especially true when it comes to working with materials like brass and stainless steel, which demand an extra level of precision and care. Custom CNC machining offers a tailored solution by allowing manufacturers to adapt tool paths, operating speeds, and other integral elements based on the specific requirements of each project. This eliminates many of the difficulties associated with standardized processes, resulting in less waste, more efficiency, and superior product quality.

Take, for example, a situation where a manufacturer was tasked with creating intricate patterns on sheets of heavy-gauge brass. Standard tools proved inadequate as they were unable to handle such fine details without causing damage or compromising on accuracy. However, using custom CNC machining allowed them to create precise, repeatable cuts while preserving the quality of the material. This demonstrated the critical importance of bespoke CNC machining solutions against traditional one-size-fits-all approaches.

The detailed process of custom CNC machining for brass and stainless steel involves the use of advanced machining techniques to produce precision parts for various industries. This process requires careful consideration of material properties, machining speed, and susceptibility to stress cracks to ensure high-quality and reliable components.

Benefits of Custom CNC Machining in Brass & Stainless Steel Production

The implementation of custom Computer Numerical Control (CNC) machining solutions in the production of brass and stainless steel components manifests an array of benefits, significantly enhancing overall manufacturing efficiency. First and foremost, CNC machines can be programmed to precisely execute complex tasks with unmatched accuracy and speed, ensuring consistent high-quality output.

Closely associated with this is a significant reduction in errors and waste compared to traditional methods due to highly precise operation-leading to cost-effective production. Indeed, once set up, these automated systems require minimal human intervention; thus labor costs are cut considerably. Moreover, their ability to work around the clock ensures maximized productivity.

- Efficiency:Custom CNC machining allows for faster, precision-based operations that drastically enhances overall manufacturing efficiency.

- Cost-effectiveness: Reduced waste and minimized human intervention lead to considerable cost savings, thereby making the production process more economical.

- Less Waste: The high level of precision leads to less waste material being produced during the manufacturing process.

- Consistent Quality: Programming capabilities ensure every outcome matches the preset standards, guaranteeing uniform quality across all units.

A classic example would be the use of CNC machining in auto spare part production where exact replicas of components are produced with absolute precision while keeping costs down through automation. Thus, from improved precision, reduced waste to enhanced production efficiency and consistency, the advantages offered by custom CNC machining make it a compelling choice in today’s competitive brass and stainless steel industry.

Common Difficulties in CNC Machining of Brass and Stainless Steel & Solutions

The application of Custom CNC Machining techniques to brass and stainless steel materials can present unique challenges for manufacturers. One common difficulty is the high cutting forces required during machining, which could potentially lead to tool wear or breakage. To mitigate this potential problem, it’s advisable to utilize advanced computer simulations that help predict these forces and therefore, optimize machining parameters accordingly. Another prevalent issue is the problematic heat generation from friction, a result often seen while working with stainless steel. This can distort the workpiece if not carefully supervised. The best remedy here involves employing effective cooling methods like constant stream flood cooling or using a coolant.

- The high level of machinability in brass makes it prone to burr formation: the protrusion left by cutting tools after machining process. Burr removal can be accomplished effectively through deburring techniques such as manual hand trimming, thermal energy method or electrochemical deburring.

- Due to its hard and tough nature, stainless steel materials are more likely to cause strain-hardening – an increase in hardness and decrease in ductility caused by plastic deformation. Manufacturers can overcome this by utilizing sharp cutting tools, slower feed rates, along with faster cutting speeds. Also, implementing regular stress-relieving post-machining processes significantly reduces residual stresses.

Conclusion

In the vast domain of manufacturing, Custom CNC Machining Solutions have come forth as an influential player especially in working with materials like brass and stainless steel. The key takeaways include its precision, lower costs, elevated productivity, reduced human error, and its ability to fabricate complex designs which are essential for industries such as Aerospace, Automotive, Medical and Energy sectors.

- Precision: The CNC machines offer an unsurpassable degree of accuracy allowing manufacturers to maintain uniformity across high volume production runs.

- Elevated Productivity: With capabilities for round-the-clock operations excluding errors commonly committed by humans; resulting in significantly heightened output levels.

- Cost-effectiveness: Reductions in waste material alongside diminished human labor expenses contributes to a noticeable decline in overall operational cost.

- Complex Fabrication Capacity: Ability to reproduce intricate geometric shapes that are beyond traditional manual methods extends their application scope substantially.

The future appears promising considering technological advancements in this sphere, particularly artificial intelligence (AI) and machine learning. As these technologies improve, CNC machining’s effectiveness will further expand, inspiring a new epoch of Manufacturing 4.0, integrating automation and data exchange trends within manufacturing technologies.

Related Posts

- Nickel Alloys in CNC Machining

Nickel alloys are widely used in CNC machining due to their exceptional mechanical properties and resistance to extreme environments. These alloys are highly valued in industries such as aerospace, automotive,…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- High-Precision CNC Machining for Military Applications

Understanding the Concept of High-Precision CNC Machining High-precision Computer Numerical Control (CNC) machining is a vital technology in numerous industries, providing an unparalleled level of accuracy and efficiency. It involves…