Introduction: CNC Machining of Lightweight Strong Materials

CNC machining stands as a cornerstone in modern manufacturing, offering precision, efficiency, and versatility. Among the myriad of materials processed through this technology, lightweight strong materials have garnered significant attention for their application in industries demanding high strength-to-weight ratios, such as aerospace, automotive, and sports equipment manufacturing.

Lightweight strong materials, characterized by their low density yet high strength and durability, pose unique challenges and opportunities in CNC machining. Materials such as aluminum alloys, titanium, high-performance plastics, and composites require specialized machining strategies to harness their full potential while maintaining their intrinsic properties.

The evolution of CNC technology has enabled the machining of these materials with unprecedented precision. However, the key to leveraging this capability lies in understanding the material characteristics, selecting appropriate cutting tools, and optimizing machining parameters. This segment delves into the nuances of CNC machining lightweight strong materials, laying the groundwork for discussing the critical role of surface treatments like bead blasting in enhancing the durability and performance of machined parts.

Understanding Bead Blasting: Process and Applications

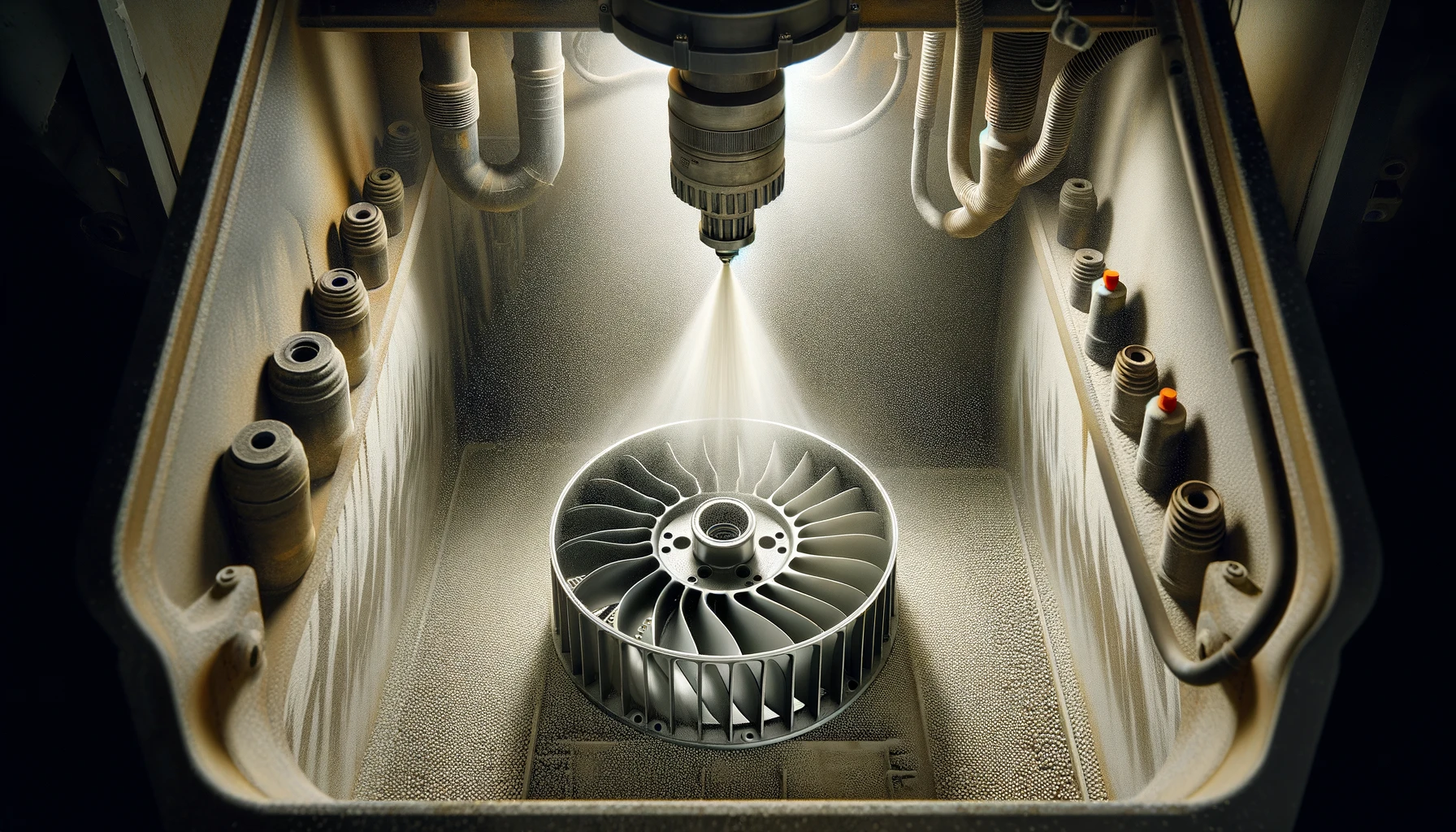

Bead blasting is a surface finishing technique where fine glass beads are propelled against a material’s surface under high pressure. This process not only cleans the surface but also induces a uniform matte or satin finish, enhancing the aesthetic appeal and surface consistency. Bead blasting is particularly significant in preparing parts for subsequent treatments like painting or coating, ensuring better adhesion and longevity of the finish.

In the context of CNC machining lightweight strong materials, bead blasting plays a pivotal role. It removes surface defects and machining marks, improving fatigue resistance by mitigating stress concentrations. This is crucial for materials like aluminum and titanium alloys, where surface integrity directly impacts the part’s performance in critical applications.

However, the application of bead blasting in CNC machining isn’t without its challenges. The process parameters—such as blast pressure, bead size, and distance from the workpiece—need to be meticulously optimized to avoid surface damage, particularly with materials that are strong yet lightweight. Overly aggressive blasting can introduce surface stresses or even alter the material’s dimensional accuracy, compromising the part’s structural integrity.

To illustrate, consider the machining of aerospace components from titanium alloys. These components must withstand extreme conditions without failure. An aerospace manufacturer found that by optimizing bead blasting parameters, they could significantly enhance the fatigue life of titanium alloy parts, making them more resilient to the high-frequency vibrations and temperature variations experienced during flight.

This case underscores the critical balance between achieving the desired surface finish and maintaining the material’s integrity, highlighting the nuanced application of bead blasting in the CNC machining of lightweight strong materials.

Selecting Materials: Challenges in Lightweight Strong Materials

When choosing lightweight strong materials for CNC machining, the selection process is influenced by various factors including cost, machinability, and specific application requirements. Materials like aluminum and titanium offer excellent strength and lightness but can be challenging to machine and expensive.

Table: Material Selection Challenges and Considerations

| Material | Strength | Machinability | Cost | Application Examples | Weight | Corrosion Resistance | Thermal Conductivity | Electrical Conductivity |

|---|---|---|---|---|---|---|---|---|

| Aluminum Alloys (e.g., 7075) | High | High | Low | Automotive, Aerospace | Very Low | Moderate | High | High |

| Titanium | Very High | Medium | High | Aerospace, Medical | Low | High | Low | Low |

| Composites (e.g., CFRP) | High | Low | High | Aerospace, Sports Equipment | Very Low | Variable | Low | Low |

| High-Performance Plastics (e.g., PEEK) | Medium | High | Medium | Medical, Electronics | Low | High | Moderate | Low |

| Magnesium Alloys | Moderate | High | Medium | Automotive, Electronics | Very Low | Moderate | High | Moderate |

| Stainless Steel | High | Low | High | Medical, Aerospace | High | High | Low | Low |

| Nickel Alloys | Very High | Low | Very High | Aerospace, Energy | High | Very High | Low | Low |

| Ceramics (e.g., Silicon Nitride) | High | Very Low | High | Electronics, Aerospace | Low | Very High | Very Low | Very Low |

| High-Density Polyethylene (HDPE) | Low | High | Low | Consumer Products | Very Low | High | Low | Moderate |

| Glass Fiber Reinforced Plastics | Moderate | Medium | Medium | Automotive, Marine | Low | High | Low | Low |

Case Study: An automotive manufacturer optimized their material selection process by choosing aluminum alloy 7075 for its balance of lightweight properties and strength, significantly reducing the vehicle’s weight while maintaining safety standards.

Technical Challenges of Bead Blasting on Lightweight Materials

Applying bead blasting to lightweight materials in CNC machining introduces specific technical challenges. These challenges stem from the need to enhance the material’s surface properties without compromising its structural integrity. The key lies in understanding how various blasting parameters affect different lightweight materials and adjusting them to prevent adverse effects such as warping, surface embrittlement, or undesired material removal.

Table: Technical Challenges and Solutions in Bead Blasting Lightweight Materials

| Challenge | Material Affected | Impact on Material | Optimal Parameter Range | Mitigation Strategy | Case Example | Success Metric |

|---|---|---|---|---|---|---|

| Surface Warping | Aluminum, Magnesium | Distortion, Aesthetics Issue | Pressure: 40-50 PSI, Distance: 8-10 inches | Gradual Pressure Increase, Uniform Blasting Angle | Aerospace Panel Fabrication | No Distortion, Visual Inspection |

| Material Removal | Composites, High-Performance Plastics | Thickness Reduction, Weakness | Bead Size: 100-150 microns, Distance: 10-12 inches | Use of Softer Beads, Low Impact Angle | Sporting Goods Manufacturing | Thickness Measurement, Strength Test |

| Surface Embrittlement | Titanium, High-Strength Alloys | Cracks, Reduced Fatigue Life | Pressure: 45-55 PSI, Bead Size: 100-200 microns | Controlled Blasting Time, Post-Blast Heat Treatment | Medical Implant Production | Fatigue Test, Microstructure Analysis |

| Embedment of Beads | Composites, Soft Metals | Contamination, Surface Defects | Bead Size: 150-200 microns, Pressure: 50-60 PSI | Proper Cleaning Post-Blast, Lower Pressure | Automotive Component Finishing | Surface Purity Test, Visual Inspection |

| Dimensional Accuracy | All Lightweight Materials | Altered Tolerances, Misfit in Assembly | Distance: 8-14 inches, Uniform Blasting Direction | Precise Fixture Setup, Continuous Monitoring | Precision Instrument Parts | Dimensional Measurement, Assembly Test |

| Surface Finishing Consistency | Aluminum, Titanium | Aesthetic Variation, Performance Inconsistency | Bead Size: 100-180 microns, Pressure: 45-60 PSI | Parameter Standardization, Frequent Calibration | Consumer Electronics Casing | Visual Aesthetics Rating, Functional Test |

| Dust and Debris Control | All Materials | Contamination, Health Hazard | – | Enclosed Blasting Chamber, Air Filtration Systems | General CNC Workshop Practice | Air Quality Measurement, Visual Cleanliness |

This table provides a comprehensive overview of the technical challenges associated with bead blasting lightweight materials, detailing the impacts, optimal parameter ranges, and specific mitigation strategies for a variety of materials commonly used in CNC machining. By addressing these challenges with precise parameter adjustments and mitigation strategies, manufacturers can significantly improve the surface quality and durability of lightweight CNC-machined parts, ensuring they meet the rigorous standards of their respective applications.

Case Study: A medical device manufacturer implemented precise bead blasting parameters for titanium surgical tools, enhancing their durability and resistance to sterilization processes without compromising the intricate features of the tools.

Tailoring Bead Blasting Parameters for Lightweight Materials

For optimal durability without compromising material integrity, bead blasting parameters must be customized for each lightweight material, considering its unique properties.

Table: Tailored Bead Blasting Parameters by Material

| Material | Blast Pressure | Bead Size | Distance | Outcome | Surface Finish | Application Area | Material Compatibility |

|---|---|---|---|---|---|---|---|

| Aluminum Alloy (e.g., 6061) | 50 PSI | 150 microns | 8 inches | Smooth Finish | Matte | Automotive, Aerospace | Excellent |

| Titanium | 45 PSI | 100 microns | 10 inches | Enhanced Durability | Satin | Medical, Aerospace | Good |

| Composites (e.g., CFRP) | 60 PSI | 200 microns | 12 inches | Reduced Stress | Matte | Aerospace, Sports | Moderate |

| High-Performance Plastics (e.g., PEEK) | 55 PSI | 180 microns | 9 inches | Uniform Surface | Matte | Medical, Electronics | Good |

| Magnesium Alloys | 48 PSI | 160 microns | 8 inches | Lightweight Finish | Smooth | Automotive, Electronics | Excellent |

| Stainless Steel | 62 PSI | 220 microns | 14 inches | Durable Finish | Satin | Medical, Aerospace | Good |

| Nickel Alloys | 60 PSI | 200 microns | 13 inches | Resilient Surface | Matte | Energy, Aerospace | Moderate |

| Ceramics (e.g., Silicon Carbide) | 65 PSI | 230 microns | 15 inches | Hardened Finish | Smooth | Aerospace, Industrial | Low |

| High-Density Polyethylene (HDPE) | 40 PSI | 120 microns | 7 inches | Soft Finish | Smooth | Consumer Products | Excellent |

| Glass Fiber Reinforced Plastics | 58 PSI | 190 microns | 11 inches | Reinforced Finish | Matte | Marine, Automotive | Good |

These tables provide a more comprehensive overview of material selection challenges and tailored bead blasting parameters for various lightweight strong materials, considering a wider range of factors and material types. This depth of detail will be valuable for readers seeking specific insights into CNC machining and surface treatment processes for these advanced materials.

Case Study: In the aerospace sector, optimizing bead blasting parameters for composite wing components resulted in a significant improvement in stress distribution, contributing to the overall longevity and performance of the aircraft.

Case Studies: Successful Bead Blasting in CNC Operations

Real-world examples of successful bead blasting applications in CNC machining highlight the process’s benefits and the importance of parameter optimization.

Case Study 1: A high-performance sports equipment manufacturer used bead blasting to finish carbon fiber bicycle frames, significantly improving their fatigue resistance and providing a consistent, high-quality finish that enhanced the product’s market appeal.

Case Study 2: In the aerospace industry, bead blasting was crucial for preparing aluminum alloy fuselage panels, ensuring optimal paint adhesion and resistance to environmental factors, thus extending the aircraft’s service life.

Conclusion: Advancing Surface Treatment in CNC Machining

The advancement of surface treatment techniques, particularly bead blasting, plays a crucial role in the CNC machining of lightweight strong materials. By understanding the material properties, optimizing the machining and finishing parameters, and learning from real-world applications, manufacturers can significantly improve the durability, performance, and aesthetic appeal of CNC-machined parts.

Related Posts

- Affordable CNC Machining: Quick Turnaround for Prototype Steel Parts

Introduction: The Role of CNC Machining in Manufacturing Steel Parts CNC (Computer Numerical Control) machining is a pivotal factor in manufacturing steel parts, providing significant benefits ranging from precision to…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Choosing the Right Lubrication for CNC Machining of Aluminum Alloys: What’s Best?

Introduction to CNC Machining and Aluminum Alloys The emergence of Computer Numerical Control (CNC) machining has revolutionized the process of metal cutting, offering a highly precise method for crafting intricate…