CNC Machining for the Space Industry: Precision in Every Part

The efficiency and reliability of the space industry hinges significantly on computer numeric control (CNC) machining. CNC machining – a manufacturing process that uses pre-programmed software to direct movements of factory machinery and tools – plays a pivotal role in producing high-quality, exact components suitable for utilization in spacecrafts, satellites, and other aerospace products. For delicate tasks such as these where minor errors can lead to catastrophic consequences, achieving utmost precision is of paramount importance.

- CNC machining offers unparalleled accuracy often with an error rate of less than 1/1000th.

- Its advanced degrees of automation minimize human intervention thereby drastically reducing chances of manual inaccuracies.

- This technology enables complex 3 dimensional cutting tasks to be executed effortlessly.

In the constantly innovating landscape of the space industry, success orbits around precision; something guaranteed through CNC machining.

Overview of CNC Machining in the Space Industry

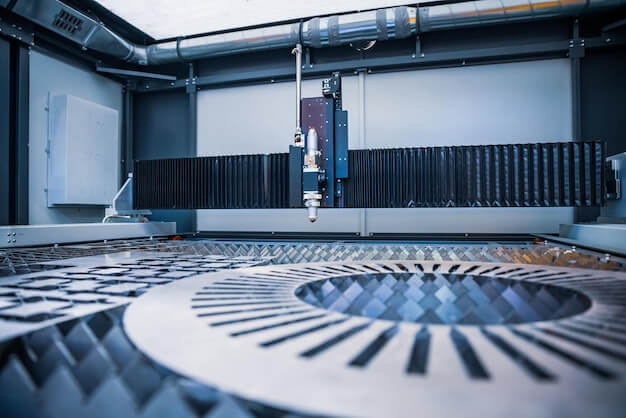

In the highly specialized space industry, Computer Numerical Control (CNC) machining is a critical technology used for manufacturing spacecraft components. This cutting-edge method is relied upon due to its extreme precision and ability to deliver consistent results even in large-scale production runs. The use of CNC machining in this context also ensures adherence to incredibly tight tolerances required by astronautics standards. It is utilized for creating intricate parts like engine components, instrument panels, brackets, enclosures, heat shields, etc., where each part’s flawless performance is crucial under challenging operating conditions.

-

The engine components – Often manufactured from tough materials such as Inconel or Titanium alloys, these parts are made using CNC machining for maximum accuracy and durability.

-

Instrument panels – These require precise cut-outs and engraving which can be efficiently done with CNC machines.

-

Brackets- Used for mounting various systems and hardware on a spacecraft, they need to fit perfectly and withstand immense pressure. Manufacturing them using CNC machining ensures strength and precision.

-

Enclosures – Housing sensitive electronic equipment that needs protection from harsh space environment, these are crafted with exact dimensions using CNC machining.

Through its notable efficiency, versatility, and detail-oriented process, CNC machining significantly contributes to advancing ambitious space missions.

The Role of Precision in CNC Machining for the Space Industry:

- Precision in CNC machining is paramount for the space industry, ensuring that every part meets the exacting standards required for space applications.

- This article delves into the role of precision in CNC machining for the space industry. Precision Machining Service

- With precision CNC machining, space industry parts can be manufactured with the highest level of accuracy and quality, meeting the stringent demands of space exploration and travel.

Benefits of CNC Machine Utilization in Space Industries

In the space industry, precision is paramount. Any significant error margin can fatally jeopardize both safety and performance of space applications. Here, Computer Numerical Control (CNC) machining emerges as an invaluable player. It substantially reduces the error margin due to its inherent superior repeatability. Replication of complex designs with extreme accuracy becomes feasible. Unlike manual machinery equipment that often results in discrepancies caused by human error, CNC machines follow specific coded instructions without deviation, ensuring remarkable consistency.

- Reliability: By reducing error margins, CNC machines offer increased reliability for producing vitally important parts for spacecrafts and satellites.

- Precision: CNC machines enable the manufacturing of intricately designed parts with a high degree of precision, essential for optimal functionality in the harsh conditions of outer space.

- Safety: Improved accuracy in component production enhances overall system safety, significantly minimizing the risk factor associated with space expeditions.

- Performance: With high consistent accuracy, CNC machines directly boost the performance of space applications, potentially leading to more successful missions.

Challenges in Adopting CNC Machining for Space-Parts Production

The adoption of Computer Numerical Control (CNC) machining in the aerospace industry is not without its challenges. A key consideration includes substantial cost implications, both from an investment standpoint and ongoing operational costs. The complexity of space equipment design often correlates with high production costs due to the requirement of precision manufacturing techniques such as CNC machining. Additionally, time constraints pose a significant challenge; intricate components can take a lengthy period to be machined precisely.

- Overcoming Cost Implications: Leveraging technological advancements can help manage cost issues effectively. The application of automation coupled with AI-powered predictive analysis could minimize wastage, streamline processes, and ultimately reduce production costs.

- Meeting Time Constraints: To overcome timing issues, implementing concurrent engineering practices enables different stages of the production process to run simultaneously, drastically reducing the overall lead-time.

Cutting-Edge Advancements: Future Impacts of CNC Machines in the Space Industry

In the increasingly progressive field of space exploration, current technological innovations have started to substantially influence CNC machining. Significant advancements include improvements in efficiency such as automatic tool changeovers and increased speed capabilities, which reduce manufacturing time – a critical factor for aerospace components.

Moving forward, IoT-enabled and AI-driven CNC machines promise even more impressive developments. These could potentially drive real-time adjustments during machining processes, ultimately leading to further accuracy and cost-effectiveness for the manufacturing of space industry parts. For example:

- AI-driven predictive maintenance can alert operators before machine failure occurs, reducing downtime.

- Data from IoT sensors may be analyzed to optimize parameters such as spindle speeds or feed rates, enhancing the overall performance of the machine.

- Upcoming breakthroughs in immersive technologies like virtual reality (VR) might be used for training purposes, enabling a higher precision and reliability.

Such emerging technologies are set to play a crucial role in future operations, allowing for continual improvement within the space industry while ensuring high levels of precision and efficiency that CNC machining is known for.

Conclusion

In conclusion, this article has underscored the indispensable role of CNC machining in the space industry. Among the main points highlighted are precision manufacturing of aerospace components, durability assurance, and cost-effectiveness of components fabrication. Moreover, we discussed how CNC machining brings about stringent conformity to specifications, an aspect that is critically important when a slight deviation could lead to catastrophic outcomes during space operations.

Reiterating, the technological advancements achieved via CNC machining have significantly propelled our capabilities in space exploration. Whether it’s about assembling a robust spaceship or constructing delicate instruments for space research, it all narrows down to the preciseness delivered by CNC machining.

- Precision Manufacturing: By leveraging automated 3D cutting, CNC machining churns out parts matching exactly with set blueprints thereby eliminating chances of error which are otherwise commonplace in manual intervention.

- Durability Assurance: The sturdiness availed by CNC machined components instills confidence even under extreme conditions prevalent in outer space.

- Cost Effectiveness: Bypassing expensive tooling processes and human labor, CNC machining turns out inexpensive in the long run despite initial setup costs being high.

The profound strides witnessed in the modern-day space industry are substantially attributable to the benefits harnessed from CNC Machining technology, reinforcing its criticality in shaping our future within and beyond earthly confines.

Related Posts

- Precision CNC Machining for the Aerospace Defense Industry

Precision CNC Machining in the Aerospace Defense Industry In modern manufacturing sectors, precision Computer Numerical Control (CNC) machining plays a critical role. It is an automated process that uses pre-programmed…

- The Evolution of CNC Machining: From Aluminum to Composite Materials

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to initiate and manipulate machine tools, such as lathes, mills and grinders. With…

- Advanced Ceramics: The Future of High-Precision Machining?

Introduction to Advanced Ceramics and High-Precision Machining In the field of manufacturing, advanced ceramics have emerged as a crucial element. These are essentially non-metallic, inorganic compounds that exhibit a range…