From Raw Material to Finished Part: A Comprehensive Guide to Technical Selection for Carbon Fiber CNC Machining

The journey from raw material to a high-performance carbon fiber reinforced polymer (CFRP) component is intricate, requiring engineers, designers, and manufacturers to carefully select among various types of carbon fiber and develop precise CNC machining strategies. The types of carbon fiber chosen—defined by precursor material, elastic modulus, weave pattern, and tow size—profoundly influence mechanical properties, […]

The Strategic Sourcing Guide to Custom CNC Machined Plastic Clips

Introduction: Navigating the Challenges of Standard Components In the dynamic landscape of manufacturing, procurement professionals, engineers, and business owners frequently encounter the limitations of off-the-shelf components. For critical parts like plastic clips, issues such as improper fit, suboptimal material selection, or inadequate performance can disrupt assembly lines, cause product failures, and compromise quality. These small […]

Beyond the Bolt: How CNC-Machined Plastic Screws Solve Modern Engineering’s Toughest Challenges

Fasteners are the unsung heroes of engineering, silently ensuring the integrity of everything from life-saving medical implants to spacecraft exploring the cosmos. For decades, metal fasteners dominated due to their strength and reliability. However, a transformative shift is underway, driven by advanced polymer science and precision CNC machining. CNC-machined plastic screws are no longer just […]

From Flaw to Perfection: How CNC Honing Solves Critical Manufacturing Challenges and Drives Profitability

Introduction: The Strategic Power of Honing in Precision Manufacturing In precision manufacturing, where tolerances are measured in microns, even minor imperfections can lead to catastrophic part failures, compromised performance, and significant financial losses. Despite substantial investments in drilling, boring, and grinding, manufacturers frequently grapple with geometric inaccuracies and suboptimal surface finishes that undermine component reliability. […]

Beyond Bronze: How CNC-Machined Plastic Bushings Solve the Core Failures of Metal Components

Executive Summary CNC-machined plastic bushings are transforming industrial applications by addressing the inherent failures of metal bushings. Unlike bronze or steel, plastic bushings eliminate lubrication needs, resist corrosion, and reduce weight and vibration. Precision-engineered from materials like PEEK, POM, PTFE, and UHMW-PE, these bushings deliver reliable, cost-effective solutions for industries such as aerospace, marine, automotive, […]

The Duality of Honing: A Comprehensive Exploration of the Precision Finishing Process from the Kitchen to the Smart Factory

Introduction: Unraveling the Honing Misconception The term “honing” spans two vastly different worlds: the culinary realm, where a honing steel is a staple for knife maintenance, and the industrial domain, where honing is a cornerstone of precision manufacturing. This semantic duality often leads to confusion, as the honing steel used by chefs to realign a […]

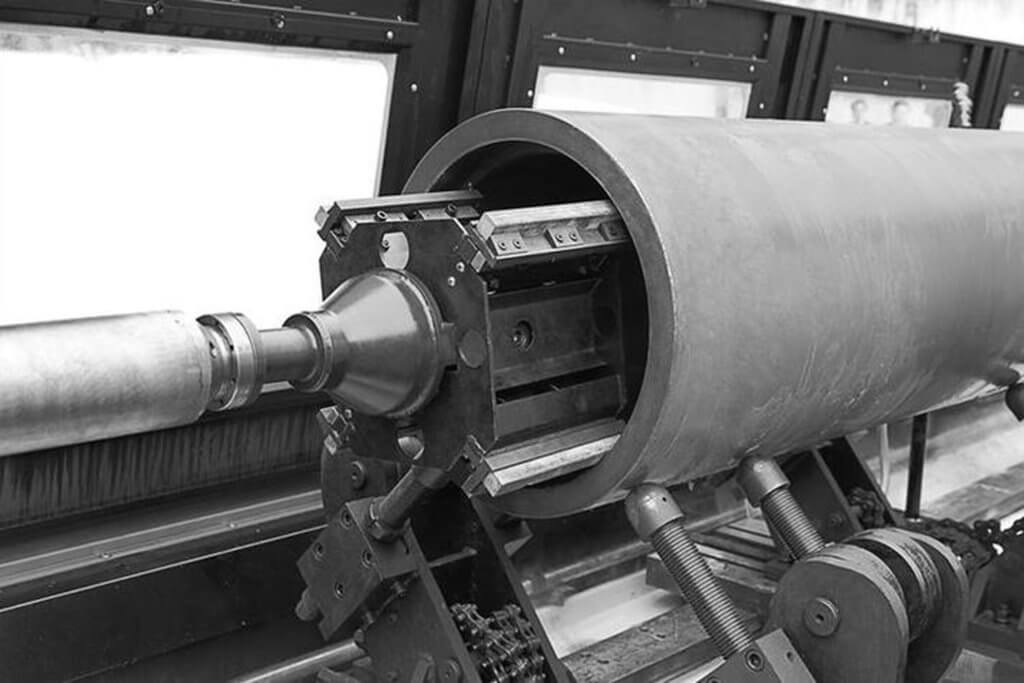

Decoding the Honing Rod: Precision Abrasives in Modern CNC Machining

The honing rod is a term that spans two distinct realms: the culinary kitchen and the high-precision machine shop. In a chef’s hands, a honing rod realigns a knife’s edge for sharpness, but in CNC machining, the honing rod refers to abrasive stones that perfect internal bores with micron-level accuracy. This article explores the industrial […]

Precision and Performance: A Technical Analysis of CNC Machining PETG Plastic for Engineers

Polyethylene Terephthalate Glycol, commonly known as PETG plastic, has solidified its position as a premier engineering thermoplastic due to its unique blend of toughness, chemical resistance, and machinability. For engineers, designers, and machinists, PETG plastic offers a versatile alternative to traditional materials like acrylic (PMMA) and polycarbonate (PC) in CNC machining applications. This comprehensive guide […]

Mastering Surface Perfection: The Role of Honing Tools in Modern CNC Machining

In the dynamic world of Computer Numerical Control (CNC) machining, achieving precise dimensions and impeccable surface characteristics is as critical as primary shaping operations. While processes like boring and reaming establish a hole’s basic geometry, they are merely the foundation for true precision. The honing tool, far from a simple finishing implement, is a sophisticated […]

Precision Perfected: The Science and Strategy of Honing Oil in CNC Machining

Introduction: The Art and Science of Precision Machining In the high-stakes world of modern manufacturing, precision is not just a goal—it’s the cornerstone of success. Industries such as aerospace, automotive, hydraulics, and medical device manufacturing rely on components engineered to microscopic tolerances. A hydraulic cylinder in an aircraft’s landing gear, an engine block in a […]

Precision Perfected: Elevating CNC Surface Finishing with Vapor Honing Technology

Introduction In the competitive landscape of precision CNC machining, achieving a flawless surface finish efficiently and consistently remains a critical challenge. Manual deburring is labor-intensive, time-consuming, and prone to human error, leading to inconsistent results that can undermine product quality. Traditional surface finishing methods, such as dry blasting, often risk damaging delicate workpieces, causing warpage, […]

Mastering the Cut: A Technical Analysis of Carbide End Mills for High-Performance CNC Machining

Introduction: The Power of Carbide End Mills in CNC Machining In the realm of Computer Numerical Control (CNC) machining, the carbide end mill stands as the cornerstone of precision, efficiency, and versatility. These advanced tools are indispensable for cutting challenging materials, from aerospace-grade titanium alloys to high-volume automotive steel components. The carbide end mill directly […]