Carbon Fiber 3D Printer: The Ultimate Guide to High-Strength, Lightweight Printing

Introduction: What Is Carbon Fiber 3D Printing? Hello there, and welcome to my ultimate guide on carbon fiber 3D printer technology. I’ve spent a good chunk of my career around additive manufacturing, and I’ve seen how the push for high-strength, lightweight materials has been an ongoing challenge for engineers, product designers, and everyday tinkerers. Today, […]

Understanding Wheel Hub Bearing And How CNC Machining Ensures Precision

Chapter 1: Why Understanding Wheel Hub Bearings and CNC Machining Matters A wheel hub bearing is a critical component in virtually every vehicle on the road.When I first learned about wheel hub bearing design, I was amazed at how much engineering goes into ensuring a smooth ride.You might think a wheel hub bearing is just […]

How to Powder Coat: A Professional Machinist’s Guide to Perfect Results

Chapter 1: Why Machinists Need to Learn Powder Coating Powder coating is a robust, eco-friendly finishing method that I’ve seen more and more machinists adopt.When people look up “how to powder coat,” they usually want to know the basic steps, equipment, and best practices.I’ve noticed it’s especially popular among those perfecting surface finishes, since powder […]

Mastering Machining of Galvanized Steel: Techniques, Challenges & Solutions

Chapter 1: Introduction – Understanding Galvanized Steel and Machining Galvanized steel is everywhere around us. From the cars we drive to the buildings we live in, galvanized steel is a trusted material. It offers excellent corrosion resistance, durability, and strength. I’ve personally dealt with galvanized steel for years in various machining applications. Initially, I thought […]

Mastering Grade 5 Titanium Machining: Cutting Tools, Coolants & Strategies

Chapter 1: Introduction to Grade 5 Titanium (Ti-6Al-4V) Grade 5 titanium, also known as Ti-6Al-4V, is a material that consistently amazes me.When I first encountered grade 5 titanium, I was working at a small machine shop that specialized in aerospace components.We had to produce a series of brackets for an aircraft manufacturer, and those parts […]

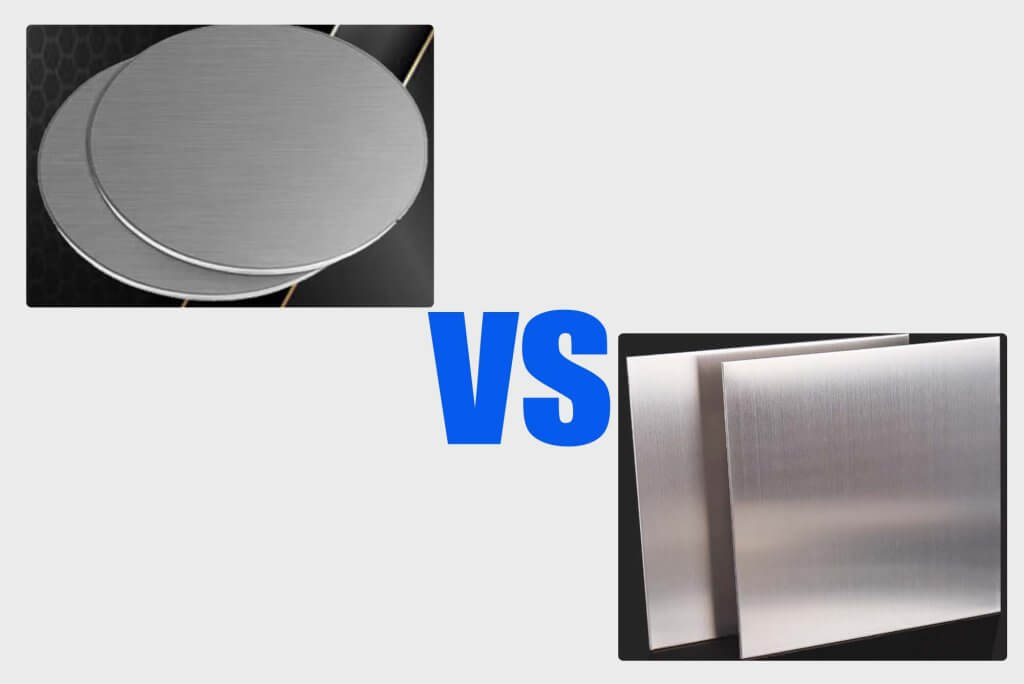

Titanium vs Steel In Machining, Manufacturing, and Engineering: A Complete Guide to Strength, Weight, and Durability

I chose this title because I wanted to provide a comprehensive overview of titanium vs steel and how each material performs in machining, manufacturing, and engineering contexts. I’ve worked with both metals on various projects, from aerospace components to everyday consumer goods. Over time, I came to see how “titanium vs steel” remains a top question among […]

The Ultimate Guide to Cast Life: Improving Machinability and Durability

I chose this title because I wanted to offer a comprehensive resource on “Cast Life” – the essential concept describing how long cast components last and how well they resist wear when subjected to machining processes. Over the years, I’ve noticed that many production lines struggle with cast parts wearing out, cracking, or failing prematurely […]

How to Manufacture Hub Centric Rings Using CNC for Maximum Accuracy

I chose this title because it highlights both the Hub Centric Rings component and the CNC manufacturing process, which ensures maximum accuracy for wheel fitment. I’ve worked with CNC machining for various automotive parts, and I’ve seen firsthand how tiny inaccuracies can cause big headaches, especially for components like hub rings. In this guide, I’ll walk you through the […]

How to Machine Polypropylene Material: A Complete Guide for CNC & Fabrication

I chose this title because I want to give a comprehensive yet approachable look at Polypropylene Material and how it’s best machined using CNC methods and other fabrication techniques. Over the years, I’ve worked with various thermoplastics, including polypropylene, and I know it can be a bit tricky if you don’t have the right techniques […]

Everything You Need to Know About Hub Bearing Assembly And CNC Machining

I chose this title because I want to provide a complete, user-friendly guide on Hub Bearing Assembly basics and how CNC machining fits into the production process. Over the years, I’ve come across many questions about what a Hub Bearing Assembly really does, why precision matters, and how CNC machining techniques help create reliable, long-lasting assemblies. In […]

How to Cut and Machine Polypropylene Sheet with CNC: A Complete Guide

I chose this title because it captures the essence of what I want to explore: the fundamental properties of polypropylene sheet, how it behaves under CNC machining, and the best techniques for cutting, drilling, and finishing this versatile material. Over the years, I’ve dealt with polypropylene sheet in various projects—from fabricating lightweight machine parts to […]

Nylon Material Properties and Applications in CNC and Other Machining Methods

I chose this title because I believe it captures the essence of what we’ll explore: the fundamental properties of nylon material, its applications, and especially its role in CNC and other machining processes. Over the years, I’ve worked on several projects that involved nylon material—from designing lightweight prototypes for automotive parts to experimenting with small-batch […]