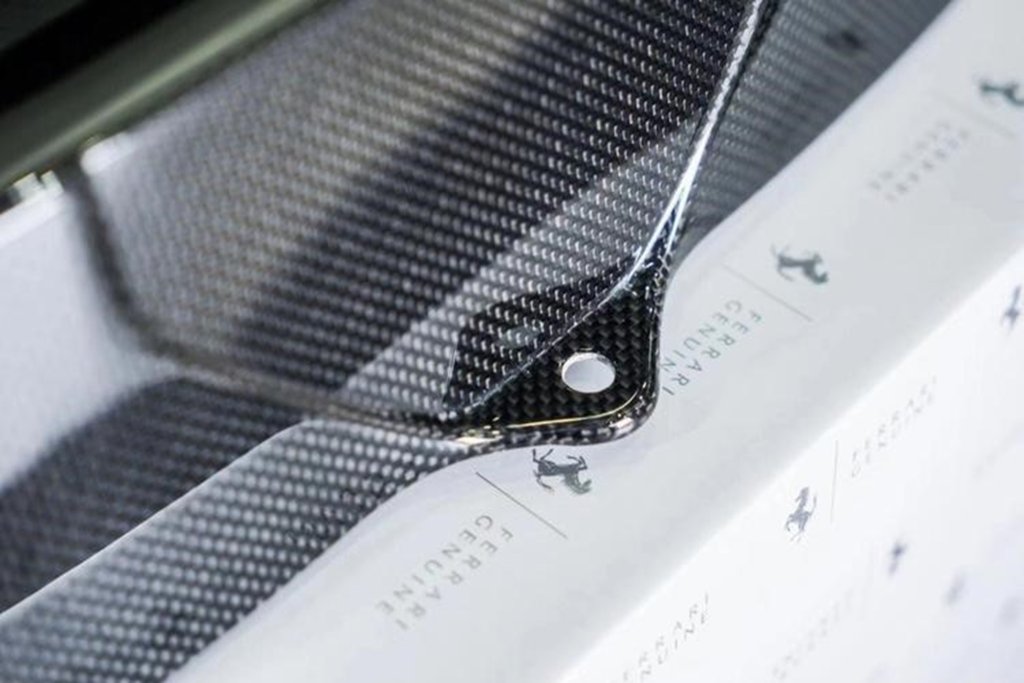

From Digital to Dynamic: The Manufacturing Technologies Shaping High-Performance Carbon Fiber Spoilers

The carbon fiber spoiler stands as a symbol of automotive performance, blending aesthetic appeal with functional excellence. Its sleek, woven surface represents speed, precision, and advanced engineering, but its true significance lies in the intricate manufacturing processes—most notably CNC machining—that transform digital designs into dynamic components. This article explores the technologies defining the quality of […]

From Raw Material to Finished Part: A Comprehensive Guide to Technical Selection for Carbon Fiber CNC Machining

The journey from raw material to a high-performance carbon fiber reinforced polymer (CFRP) component is intricate, requiring engineers, designers, and manufacturers to carefully select among various types of carbon fiber and develop precise CNC machining strategies. The types of carbon fiber chosen—defined by precursor material, elastic modulus, weave pattern, and tow size—profoundly influence mechanical properties, […]

Precision and Performance: A Technical Analysis of CNC Machining PETG Plastic for Engineers

Polyethylene Terephthalate Glycol, commonly known as PETG plastic, has solidified its position as a premier engineering thermoplastic due to its unique blend of toughness, chemical resistance, and machinability. For engineers, designers, and machinists, PETG plastic offers a versatile alternative to traditional materials like acrylic (PMMA) and polycarbonate (PC) in CNC machining applications. This comprehensive guide […]

Nylon 12 CNC Machining: A Comprehensive Guide to Material Science and Precision Manufacturing

Introduction to Nylon 12: A High-Performance Thermoplastic Nylon 12, also known as Polyamide 12, is a high-performance engineering thermoplastic widely adopted in CNC machining for its exceptional combination of toughness, chemical resistance, and dimensional stability. These properties make Nylon 12 a top choice for precision components in industries such as aerospace, automotive, medical, and industrial […]

Titanium Carbide (TiC) in CNC Machining: Optimizing Performance, Advanced Tooling, and High-Speed Applications

Introduction: Beyond Hardness—Why Titanium Carbide is a Game-Changer in Modern Machining In precision manufacturing, the pursuit of speed, accuracy, and efficiency drives innovation. The evolution of Computer Numerical Control (CNC) machining has enabled the automated production of complex parts. However, a machine’s performance hinges on the capability of its cutting edge. Titanium carbide emerges not […]

Tungsten Carbide: From Powder to Performance in CNC Machining

I. Introduction: The Powerhouse Behind Precision CNC Machining In the fast-paced world of precision manufacturing, where aerospace components demand flawless tolerances and medical implants save lives, one material reigns supreme: tungsten carbide. But what is carbide? Known simply as “carbide” on the shop floor, this extraordinary composite is the heart of modern CNC machining. It […]

Machining the ‘Black Diamond’: A Comprehensive Guide to Advanced CNC Techniques for Boron Carbide

Boron carbide, often hailed as the “black diamond,” is an advanced ceramic renowned for its extraordinary hardness, surpassed only by diamond and cubic boron nitride (cBN). Its unique blend of extreme hardness, low density, and neutron absorption makes it indispensable in defense, aerospace, and nuclear industries. Yet, this same hardness poses a formidable challenge in […]

Silicon Carbide and CNC Machining: A Comprehensive Technical Analysis of Materials, Processes, and Applications

Introduction Silicon carbide (SiC) stands as a pinnacle of advanced ceramics, engineered to thrive in environments that push materials to their limits. Its extraordinary hardness, thermal resilience, and chemical stability make it a vital component in industries ranging from semiconductor manufacturing to aerospace engineering. However, the very properties that elevate silicon carbide also make CNC […]

Cemented Carbide: The Material Science and Application Strategies Driving High-Performance CNC Machining

Part 1: The Material Science of Cemented Carbide: The Core of CNC Machining As a machinist with 15 years of experience, I’ve come to appreciate cemented carbide as the unsung hero of CNC machining. Its ability to withstand intense conditions while delivering precision has revolutionized my work. Let’s explore what makes carbide so vital, from […]

The Backbone of Industry: A Deep Dive into Stainless Steel Pipe

Chapter 1: Unveiling Stainless Steel Pipe Essentials 1.1 What Makes Stainless Steel Pipe Exceptional Having spent years specifying materials for industrial systems, I’ve come to rely on stainless steel pipe for its unmatched reliability. It’s a hollow, cylindrical tube crafted from an iron-based alloy containing at least 10.5% chromium, which forms a self-repairing oxide layer […]

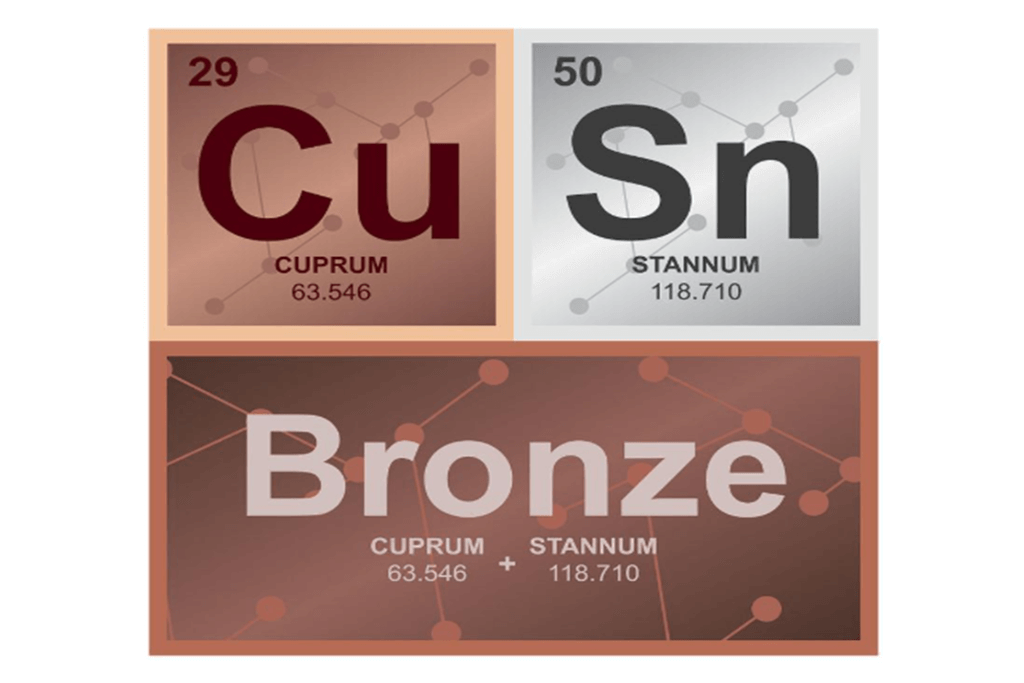

Copper vs. Bronze for CNC Machining: A Comprehensive Technical Comparison

In the world of CNC machining, selecting between copper and bronze is a pivotal decision that shapes a component’s performance, manufacturability, and cost. As an engineer who’s spent years navigating material choices for precision parts, I’ve seen firsthand how the copper vs. bronze debate can make or break a project. These “red metals” share a […]

Mastering Steel in CNC Machining: Harnessing the Yield Strength of Steel for Precision, Performance, and Profitability

In the intricate world of CNC machining, the yield strength of steel stands as a cornerstone metric that shapes the performance, reliability, and cost-effectiveness of precision-engineered components. As an engineer with over a decade of experience in designing and machining high-performance parts, I’ve seen firsthand how this critical property influences every decision—from material selection to […]