Introduction to CNC Machining and Challenges with Soft Materials

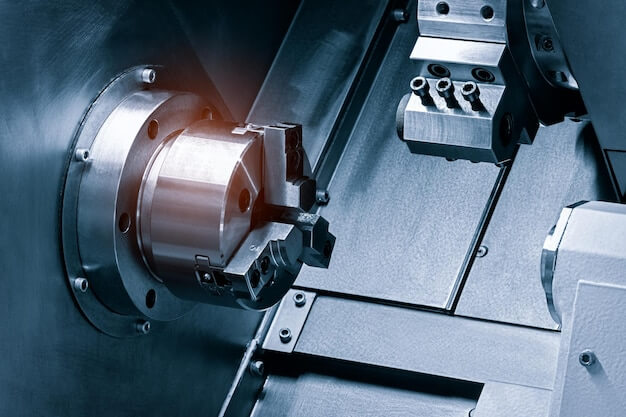

CNC (Computer Numerical Control) machining is a core operation in the manufacturing sector, powering the production of complex parts across various industries. It involves programming computers to direct machinery, such as mills, grinders and lathes, to manufacture components to precise specifications. Despite its versatility, working with soft materials presents unique challenges. These include difficulty maintaining material integrity due to low rigidity and susceptibility to tool pressure which may lead to dimensional inaccuracies.

- Maintaining Material Integrity: Soft materials can easily deform under high speed and pressure during CNC processing, leading to damage or loss of shape.

- Dimensional Inaccuracy: Due to their flexibility, it’s hard for soft materials to hold tight tolerances, resulting in deviations from desired measurements.

Tackling these issues requires specific techniques and expertise – matters that this article will delve further into in subsequent sections.

Understanding Soft Materials in CNC Machining

In the context of CNC Machining, “soft” materials refer to substances such as aluminum, rubber, and different varieties of plastics. They are classified as soft due to their lower hardness ratings on the Brinell or Rockwell scales compared to harder materials like stainless steel or titanium. Handling these types of materials presents unique challenges primarily because of their malleability and tendency for mechanical deformity under high-speed machining processes.

- Aluminum: Despite its relative softness, aluminum’s good thermal conductivity can cause it to heat up quickly during machining, leading to potential warping or distortions.

- Rubber and Plastics: These materials demonstrate a higher level of flexibility, which makes them prone to vibrations and inaccuracies during drilling or milling operations.

Contrarily, harder counterparts possess greater resistance to deformation, providing inherent stability during machining. Hence, understanding these material-specific behaviors is crucial for strategizing optimal cutting parameters and tooling choices to mitigate potential issues.

Common Challenges in CNC Machining with Soft Materials

When working with soft materials using Computer Numerical Control (CNC) machining, a number of issues often arise. These can include the potential for distortion and tearing, as well difficult burr formations. Distortion occurs due to the force exerted by the cutting tools which may deform the material instead of cutting it neatly.

For example, machining a soft plastic or rubber component could result in the part losing its required shape because these materials do not have the stiffness to withstand significant pressure from the machining process. Tearing is another common problem when machining materials such as foam or silicone, where the cutting tool might rip off pieces of material rather than cleanly slicing through it.

Lastly, burr formation, unwanted tiny parts that stick out from the surface of the machined item, are problematic. A notable instance is observed while milling an aluminum sheet; due to its malleability, it tends to form more burrs as compared to harder metals. Each of these challenges demands careful planning, precise adjustments on machine configurations, and the application of suitable techniques to mitigate or avoid adverse effects on the final product.

Techniques for Overcoming Challenges in CNC Machining with Soft Materials

When it comes to CNC machining with soft materials, certain challenges may arise due to the unique properties of these materials. However, there are techniques and tips that can help overcome these challenges and achieve successful machining results. Let’s explore these techniques:

1. Tool Selection:

- Choosing the right cutting tools is crucial when machining soft materials.

- Tools with sharp cutting edges and low rake angles are preferred to minimize material deformation and achieve clean cuts.

- Consider using high-speed steel (HSS) or carbide tools, as they offer excellent cutting performance and durability.

2. Cutting Parameters:

- Optimizing the cutting parameters is essential for machining soft materials.

- Lower cutting speeds and feed rates should be used to prevent excessive material deformation or burrs.

- Reducing the depth of cut can also help maintain dimensional accuracy and surface quality.

3. Workholding and Support:

- Soft materials may be more prone to deformation during machining, so proper workholding and support are crucial.

- Using fixtures or clamps that provide adequate support and minimize vibrations can help maintain part stability and prevent material shifting.

4. Cooling and Lubrication:

- Applying cooling and lubrication during machining can help control heat buildup and reduce friction.

- Using coolants or lubricants can improve chip evacuation, prevent tool overheating, and enhance surface finish.

By implementing these techniques, manufacturers can overcome the challenges associated with CNC machining soft materials and achieve high-quality results. For professional CNC machining services and expert advice on machining soft materials, you can rely on our online CNC service.

Key Tips for Successful CNC Machining with Soft Materials

In the realm of CNC machining, working with soft materials often poses unique challenges. However, certain strategies and techniques can significantly aid in overcoming these difficulties. One key tip is regular machine maintenance which plays a crucial role in minimizing potential damages. Ensuring that your equipment is consistently at its best condition makes it more efficient and less prone to errors that could ruin your workpiece. Keeping all parts perfectly aligned, regularly replacing worn out components, and maintaining cleanliness are some of the basic yet vital aspects of machinery upkeep.

A second recommendation involves the utilization of cutting-edge software. Modern software solutions have brought immense precision and efficiency into the field of CNC machining with their capacity to create detailed digital renditions of the final product, analyse possible areas of error, and help you refine designs before actual production begins.

The last but not the least important point accentuates continuous learning and practice. Mastering CNC machining with soft materials does not happen overnight; rather it’s an ongoing process involving strategic understanding, experimentation, evaluation, and refinement. Whether it’s studying new material behaviours, testing different tools, or experimenting with varying speeds and feeds, there’s always something valuable to learn that elevates your existing skills further.

Conclusion

In conclusion, CNC machining with soft materials poses unique challenges that can be effectively navigated using certain techniques. Techniques discussed in this article such as cooling during the process, ensuring the use of sharp tools and using electrochemical machining have proven to significantly optimize the machining process. The path to better results in dealing with softer materials lies in understanding these techniques and consistently implementing them. Overcoming challenges associated with CNC machining soft materials is not instant but a result of dedicated effort over time.

- Cooling: Helps manage heat generated to prevent deformation or damage.

- Sharp Tools: Ensures smooth cuts minimizing instances of material pulling or sticking on the tool.

- Electrochemical Machining (ECM): A non-traditional method which uses electrical discharges for the machining process.

The technical principles discussed previously emphasize that there are strategies that can help effectively harness the full potential of CNC machines even when dealing with soft materials. Thus, success in CNC machining with soft materials is fully attainable through a consistent combination of the right knowledge, skills and application of validated methodologies.

Related Posts

- The Future of Biomedical CNC Machining: Innovations in Material Compatibility and Functionality

Introduction to Biomedical CNC Machining Biomedical CNC (Computer Numerical Control) machining stands as a cornerstone in the development of medical devices, enabling the precise fabrication of complex parts essential for…

- CNC Machining: Understanding Materials, Processes and Techniques( rivets Nora)

When it comes to Computer Numerical Control (CNC) machining processes utilised in manufacturing industries worldwide, there’s an expansive range of materials, procedures and techniques that play a crucial role. These…

- Understanding CNC Machining: From Materials to Techniques( anodized aluminum Linda)

In the world of precision machining, Computer Numerical Control (CNC) technology plays a critical role. With an array of materials such as titanium, aluminum, cast iron steel, and innovative techniques…