Introduction to CNC Machining

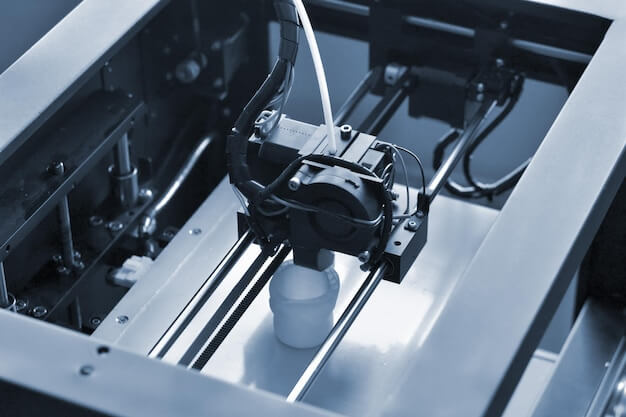

CNC (Computer Numerical Control) machining stands as a pivotal technology in the manufacturing of optical components, enabling the precise shaping of materials with minimal human intervention. This process is crucial for creating intricate parts used in various optical applications, from lenses to mirrors. Focusing on materials like glass and polycarbonate, CNC machining offers the versatility to work with the unique properties of each. Glass, known for its clarity and durability, and polycarbonate, valued for its lightweight and impact resistance, are both shaped effectively through CNC machining to meet specific optical requirements. For instance, the production of a polycarbonate lens involves precise cutting and shaping to achieve the desired optical clarity and light transmission, showcasing the technology’s capability to handle different material characteristics.

Understanding Optical Components

Optical components are crucial elements in various devices, playing a pivotal role in manipulating light to achieve desired outcomes. These components are integral in applications ranging from simple magnifying glasses to complex laser machining systems. Common types of optical components include:

- Lenses: Focus or diverge light beams.

- Mirrors: Reflect light, altering its path without changing its wavelength.

For instance, a lens in a camera focuses light onto the sensor, capturing clear images, while mirrors in telescopes gather and focus light from distant stars, enabling detailed observation. By precisely controlling light, these components fulfill their roles in enhancing the functionality of optical devices.

Basics of Glass and Polycarbonate

Understanding the properties of glass and polycarbonate is essential for enhancing optical components through CNC machining. Glass, known for its exceptional clarity and high resistance to scratches, is often used in applications requiring precision and durability. However, it is heavier and more brittle, making it susceptible to breakage upon impact. On the other hand, polycarbonate is a lightweight alternative that offers significant impact resistance, albeit with slightly lower clarity and more susceptibility to scratches. For instance, while glass might be preferred for the lenses of high-quality cameras due to its clarity, polycarbonate is often chosen for safety glasses where impact resistance and weight are critical considerations.

- Durability: Glass is more resistant to scratches, while polycarbonate is less likely to break upon impact.

- Clarity: Glass provides superior optical clarity compared to polycarbonate.

- Weight: Polycarbonate is significantly lighter than glass, making it suitable for applications where weight is a concern.

Advantages of CNC Machining for Optical Components

CNC machining stands out in the manufacturing of optical components due to its exceptional precision and flexibility in shaping materials. This process allows for the creation of complex shapes and high-precision parts that are essential in optical applications. For instance, when fabricating a lens from polycarbonate, CNC machining can achieve the intricate curves and exact dimensions required for optimal light transmission and focus. The advantages include:

- High Precision: CNC machining controls the cutting process down to fractions of a millimeter, ensuring components meet strict specifications.

- Material Flexibility: It can shape a wide range of materials, from glass to polycarbonate, allowing for diverse optical applications.

- Complex Shapes: The ability to produce complex geometries that are otherwise difficult to achieve with traditional manufacturing methods.

Challenges in Machining Glass and Polycarbonate

When it comes to CNC machining optical components, challenges may arise when working with glass and polycarbonate due to their unique properties. Glass requires specialized tooling and careful handling to prevent breakage, while polycarbonate demands precise machining to maintain its optical clarity and structural integrity.

Choosing Between Glass and Polycarbonate

When selecting materials for optical components, the choice between glass and polycarbonate hinges on specific application requirements. Key criteria include:

- Weight: Polycarbonate is significantly lighter than glass, making it preferable for applications where weight is a critical factor, such as in aerospace or wearable devices.

- Impact Resistance: Polycarbonate offers superior impact resistance, ideal for safety lenses, sports eyewear, and environments where the risk of impact is high.

- Optical Clarity: Glass provides better optical clarity and is more resistant to scratching, making it suitable for high-precision optical instruments like cameras and microscopes.

For instance, in the production of eyewear for sports, polycarbonate is often chosen for its lightweight and high impact resistance, ensuring both comfort and protection for the wearer.

Future Trends in CNC Machining of Optical Components

The evolution of CNC machining for optical components, specifically glass and polycarbonate, is poised to be significantly influenced by emerging technologies and methods. These advancements aim to enhance precision, efficiency, and the range of achievable designs. Key future trends include:

- Adaptive Machining: This technology allows for real-time adjustments during the machining process, improving accuracy for complex shapes and reducing waste.

- Ultra-Precision Machines: New generations of CNC machines offer higher precision levels, capable of achieving nanometer accuracy, crucial for advanced optical applications.

- Laser-Assisted Machining: Integrating lasers with CNC machining can cut harder materials more cleanly and with greater detail, beneficial for both glass and polycarbonate components.

For example, adaptive machining can adjust cutting parameters on-the-fly based on sensor feedback, optimizing the process for each unique piece and ensuring higher quality finishes with fewer defects.

Related Posts

- High-Precision CNC Machining for Custom Optical Lenses

Introduction to CNC Machining and its Significance in Custom Optical Lenses CNC - Computer Numerical Control machining, is a highly precise process employed for the production of complex parts with…

- Ceramic CNC Machining: Advantages and Limitations for Industrial Applications?

Ceramic CNC Machining: Advantages and Limitations for Industrial Applications As the demand for precision in industrial applications continues to rise, manufacturers have turned to advanced solutions like Computer Numerical Control…

- Prototype CNC Machining of Titanium Alloys: Achieve Superior Accuracy

Introduction to CNC Machining and Titanium Alloys CNC (Computer Numerical Control) Machining is a high-precision manufacturing process where pre-programmed computer software directs the movement of factory tools and machinery. This…