1. Introduction: Unveiling the Versatility of Bead Blasting

In this opening section, we introduce the concept of bead blasting in CNC machining and set the stage for an in-depth exploration of its multifaceted applications. We highlight the significance of surface treatment and the role bead blasting plays in enhancing various aspects of CNC machined products.

2. Diverse Industries Benefiting from Bead Blasting

Delving into practical applications, this section provides a detailed list of industries that benefit from the multifaceted applications of bead blasting in CNC machining:

- Aerospace: Precision cleaning and surface preparation for aircraft components.

- Medical Devices: Achieving smooth and sterile surfaces for implants and medical instruments.

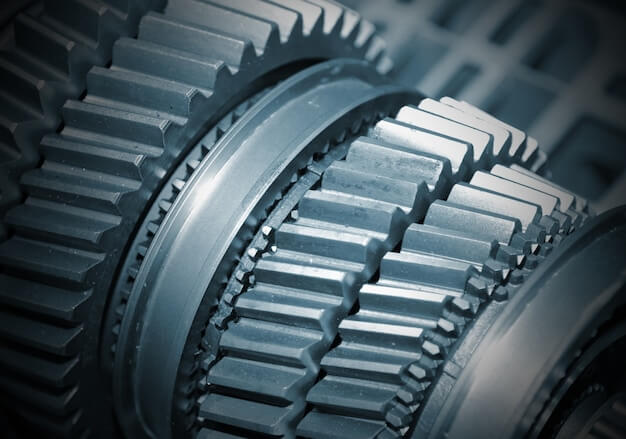

- Automotive: Enhancing the aesthetic appeal and corrosion resistance of automotive parts.

- Electronics: Improving conductivity and ensuring cleanliness in electronic components.

- Architectural Components: Surface finishing for decorative and functional architectural elements.

3. Precision Surface Preparation: The Art and Science of Bead Blasting

This section explores the intricate details of how bead blasting contributes to precision surface preparation. From selecting the right abrasive media to understanding pressure and nozzle configurations, readers gain insights into the art and science behind achieving optimal surface conditions.

4. Quality Enhancement: Bead Blasting’s Impact on Product Aesthetics and Functionality

Examining the impact on product quality, this section discusses how bead blasting enhances both the aesthetics and functionality of CNC machined products. From achieving consistent surface finishes to addressing material compatibility, we explore how quality is elevated through bead blasting.

5. Innovative Approaches: Future Trends and Advancements in Bead Blasting

Concluding the article, we look towards the future of bead blasting in CNC machining. By discussing emerging trends, technological advancements, and innovative approaches, we provide a forward-looking perspective on how bead blasting is likely to evolve in the ever-changing landscape of CNC machining.

By the end of this comprehensive exploration, readers will have gained a profound understanding of the multifaceted applications of bead blasting in CNC machining, its diverse industry uses, the art and science of precision surface preparation, the impact on product quality, and a glimpse into the future trends shaping the world of bead blasting.

Related Posts

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…