Introduction to CNC Machining and Non-Conductive Materials

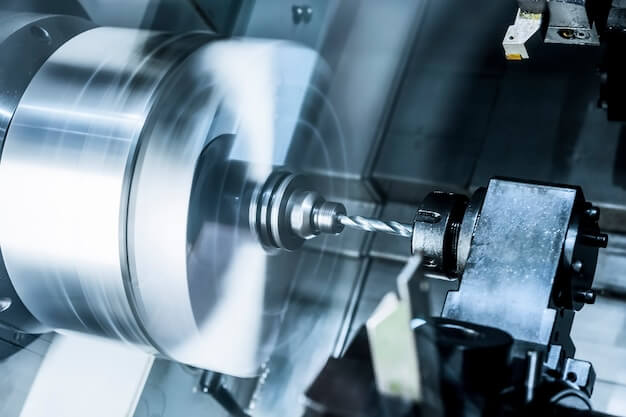

CNC machining stands for Computer Numerical Control machining, a process where computers control the movement and operation of machines that shape materials. This technique allows for precise cutting, drilling, and shaping of various materials based on digital designs. Non-conductive materials, such as ceramics, glass, and certain plastics, are often used in industries like electronics and aerospace for their insulating properties and resistance to heat and corrosion. These materials pose unique challenges in CNC machining due to their brittleness and the inability to use electrical conductivity-based monitoring techniques.

- Computer Numerical Control (CNC) Machining: A precision manufacturing process controlled by digital instructions.

- Non-Conductive Materials: Types include ceramics, glass, and plastics, chosen for their insulating properties.

Challenges of Machining Non-Conductive Materials

The process of machining non-conductive materials presents unique challenges primarily due to their electrical properties and material characteristics. Non-conductivity complicates machining because traditional methods like Electrical Discharge Machining (EDM) rely on electrical conductivity to shape the material. Consequently, alternatives that do not depend on electrical properties must be used, often leading to increased complexity and cost. The material characteristics of non-conductive materials such as hardness and brittleness further affect the machining process. For example:

- Hardness: Harder materials require more force and energy for machining, leading to higher wear and tear on tools.

- Brittleness: Brittle materials can easily crack or chip during machining, demanding precise control and techniques to avoid damage.

An example of these challenges can be seen in machining ceramics, a non-conductive material known for its hardness and brittleness. Specialized tools and techniques, such as diamond grinding or ultrasonic machining, are often required to effectively shape ceramics without causing damage.

Understanding the Pain Points

When machining non-conductive materials, professionals often encounter specific challenges that can impact the efficiency and quality of their work. Among these challenges, precision, tool wear, and material waste stand out as common issues. For instance, machining fiberglass, a non-conductive material, presents unique difficulties. The abrasive nature of fiberglass leads to rapid tool wear, necessitating frequent replacements and adjustments to maintain precision. This not only increases the material waste due to inaccuracies and the need for rework but also elevates the overall cost and time investment in the machining process. Addressing these pain points requires a meticulous approach to tool selection, process optimization, and material handling to minimize waste and wear while ensuring high precision.

- Precision: Achieving high accuracy in dimensions and finishes, crucial for the functionality and aesthetics of the final product.

- Tool Wear: Frequent tool replacement due to the abrasive nature of materials like fiberglass, impacting cost and downtime.

- Material Waste: Increased waste from inaccuracies and the need for rework, affecting efficiency and sustainability.

Technological Solutions

When facing the challenges of CNC machining non-conductive materials, technological solutions such as specialized tooling and advanced machining techniques can be employed to overcome these obstacles. Additionally, utilizing CNC machines with enhanced capabilities for non-conductive materials can significantly improve the machining process.

Practical Tips for Success in CNC Machining Non-Conductive Materials

When machining non-conductive materials, two critical steps ensure success: material preparation and tool selection. Material preparation involves cleaning the material surface to remove any contaminants and applying a suitable release agent if necessary. This step is crucial for enhancing the material’s machinability and preventing tool damage. For example, applying a thin layer of release agent on composite materials can significantly reduce tool wear. Tool selection is about choosing the right tools that are specifically designed for non-conductive materials. These tools often have unique geometries and coatings to minimize wear and tear, and to extend tool life. For instance, diamond-coated tools are excellent for machining graphite and composite materials due to their superior wear resistance.

- Material Preparation: Clean surface, apply release agent.

- Tool Selection: Use tools with special geometries and coatings for non-conductive materials.

Case Study: Machining a Complex Part from a Non-Conductive Material

In a notable project, a team successfully machined a complex part from a non-conductive ceramic material, which is often challenging due to its lack of electrical conductivity that complicates traditional CNC machining processes. The project’s success hinged on several key technical principles and adaptations:

- Material Selection: Choosing a ceramic material that, despite being non-conductive, could withstand the mechanical stresses of machining.

- Tooling Adaptation: Utilizing diamond-coated tools to reduce wear and improve precision.

- Process Optimization: Adjusting machining parameters such as speed, feed rate, and cooling to minimize cracks and fractures.

The project underscored the importance of meticulous planning and adaptation in machining non-conductive materials. Lessons learned include the critical role of tool selection and the need for process adjustments to accommodate the unique properties of non-conductive materials. This case serves as a practical example of overcoming the challenges associated with machining complex parts from non-conductive materials.

Related Posts

- Graphite vs. Steel: Which Material Offers Better Performance in CNC Tooling Applications?

Introduction to CNC Tooling CNC tooling, an abbreviation for Computer Numerical Control tooling, is a method extensively used in the manufacturing sector. This technology automates machine tools with high-level programming…

- Graphite vs. Steel: Which Material Offers Better Performance in CNC Tooling Applications?

Introduction to CNC Tooling CNC tooling, an abbreviation for Computer Numerical Control tooling, is a method extensively used in the manufacturing sector. This technology automates machine tools with high-level programming…

- Exploring CNC Turning and Different Types of Rivets(cantilever snap joint Nicholas)

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry in ways few could have imagined. Among several processes, CNC turning stands out as both a cost-effective and efficient method…