What is CNC? This acronym stands for Computer Numerical Control, a technology that has significantly revolutionized various sectors including manufacturing, engineering, and design. CNC machining is automated control over specialized machinery using a computer system that reads data-driven instructions known as G-code.

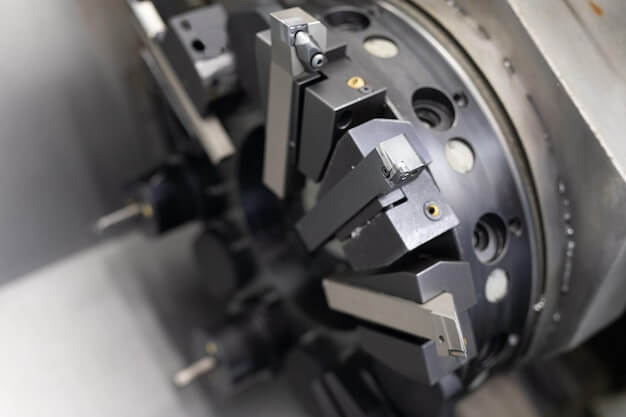

CNC machines are distinguished from conventional devices due to their ability to carry out complex cuts efficiently on different materials such as metal, wood or plastic, among others at considerable speeds with high precision. Its intricate operation involves subtractive processes like drilling, milling, turning, and lathing.

CNC machining operates by following coded programming instructions without manual operator intervention, ensuring not just repeatability but also accuracy. The intricately detailed results of each cut made often exceed what any human could produce manually which makes it highly reliable.

So how does one produce this wonder of modern engineering?

The first step in the process of creating these specialized machines is drafting a meticulous blueprint detailing every component involved in its making. Engineers using CAD (Computer-Aided Design) software develop 3D models of the item to be created, incorporating all dimensions and geometries.

Next, these blueprints are translated into a series of numerical codes or commands recognizable by CNC machines – an operation typically achieved through CAM (Computer Aided Manufacturing) programs.

Upon completion of programming, the machine is set up with the necessary tools required for material cutting maneuvers. Various factors such as feed rate, coordination, position, and speed are cautiously calculated and programmed into the system before launching the manufacturing procedure. After setting up, the workpiece is loaded into the CNC machine, usually fixed onto a mounting table using a vice or clamps.

The real action ensues once the CNC machine starts running based on the given instructions, cutting and shaping the workpiece accurately as programmed. Skilled operators supervise the entire process constantly monitoring and adjusting the setup if needed, to ensure machine efficiency and product accuracy.

CNC machining boasts of a variety of benefits. Foremost among these is enhanced automation that reduces operator-associated strain and errors, maintaining high standards of quality. It’s also highly scalable making it suited for both small bespoke projects as well as large-scale industrial manufacturing.

Conclusively, CNC machinery provides precision, reducing waste in the process while saving time unlike manual machining. With modern advancements such as 3D printing and AI seamlessly complementing automated manufacturing, there’s no doubt that CNC machining will continue to facilitate innovation across industries, redefine productivity, and drive economic growth.

Understanding what CNC signifies and its myriad capabilities underlines the technology’s indispensable role from everyday products, component parts to intricate artwork, thus effortlessly blending science, creativity, and industry into one exciting subject matter. Regardless of how simple or complex your project might be, you’ll find that exploring the world of CNC machining more than answers the question “what is CNC,” and opens up new vistas of design possibilities waiting to be discovered.

Related Posts

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- CNC Machining for the Renewable Energy Sector: Material Choices for Durability and Efficiency

Introduction to CNC Machining in the Renewable Energy Sector CNC (Computer Numerical Control) machining stands as a pivotal manufacturing process in the renewable energy sector, enabling the precise production of…