Precision CNC Machining Service: High-Quality Titanium Parts

In the world of manufacturing, precision Computer Numerical Control (CNC) machining plays a pivotal role. This technology-driven process utilizes pre-programmed software to regulate a broad range of complex machinery including grinders, lathes, and mills. Precision is key in this operation as even the slightest error can vastly affect product quality.

High-quality titanium parts, often crafted using precision CNC machining, hold immense significance across diverse industries such as aerospace, medical and automotive fields to name a few. The use of titanium aligns with various benefits which include corrosion resistance, light weight and remarkable strength. These features thereby make it an essential material for creating durable and high-performance components.

- Titanium’s commendable strength-to-weight ratio makes it preferred choice for aircraft structures and engines, significantly enhancing their efficiency and durability.

- In the automotive industry, manufacturers leverage titanium parts for their excellent heat resistance – critical when designing exhaust systems or engine components.

- The biocompatibility feature of titanium finds its way into medical industry, commonly used for surgical instruments, orthopedic implants, or prosthetic devices.

The industrial applications of high-quality titanium parts are vast, underscoring the importance of precision CNC machining services in modern day manufacturing processes.

Understanding the Basics: The CNC Machining Process

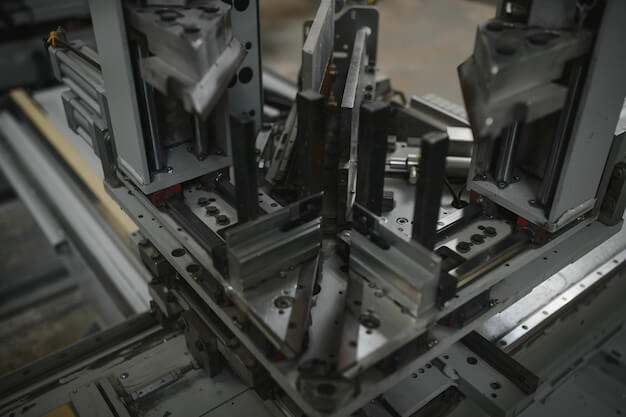

- CNC machining is a subtractive manufacturing process that uses computerized machine tools to create custom-designed parts.

- The process involves the use of CAD and CAM software to create a design and translate it into manufacturing instructions for the CNC equipment.

- Skilled machinists then load the instructions into the machine, which automatically performs actions like cutting, milling, turning, and electrical discharge machining to achieve the final product.

Titanium as a Key Material in Precision CNC Machining

In the world of precision CNC machining, the utilization of titanium is highly valued due to its remarkable properties. Critical to understand are some key characteristics that make it a preferred material for manufacturing processes. Firstly, titanium boasts an impressive strength-to-weight ratio – remarkably high even among metals. This feature alone makes it exceedingly optimal for parts requiring both durability and lightness.

Secondly, its corrosion resistance abilities set it apart. When exposed to air or water, titanium forms a thin layer of oxide on its surface providing exceptional protection against rust and deterioration.

Thirdly, being biocompatible, titanium does not cause any harm when introduced into living tissue making it a favored selection throughout the medical sector.

Moreover, titanium’s ability to withstand extreme temperatures sets it ahead of other materials; thus often chosen for manufacturing processes within various sectors such as aerospace, automotive, and defense. These unique qualities illustrate why titanium isn’t just valuable but rather vital in the realm of CNC machining services.

The Significance of Precision in CNC Machining

Precision CNC machining is a highly critical process that involves creating parts with exact specifications using computer numerical control (CNC) equipment. It’s a modern technique, which enables high level of accuracy and repeatability while working with strong materials like titanium.

- Explanation: Precision CNC machining, by definition, refers to the automation method where pre-programmed software dictates movement and functioning of machinery tools. As opposed to manual input, it expedites production speed, reduces errors and improves precision level especially when designed for complex geometries or tasks.

- Importance: The importance of Precision CNC machining particularly shines through when producing titanium components. Titanium is known for its strength and durability, but its hardness also means it’s difficult to work with, increasing the chances for errors. Hence, the preciseness offered by CNC machining becomes crucial to avoid waste in materials and ensuring reliability in part functionality. An excellent example can be seen in aerospace industry where titanium parts have to withstand extreme conditions – any minute deviation could compromise safety, thereby highlighting this technology’s significance.

Industries Benefiting from High-Quality Titanium Parts

The utility of high-quality titanium parts in precision CNC machining services spans across multiple thriving industries. Foremost among these are the aerospace, medical, and automotive sectors. In aerospace, titanium’s strength-to-weight ratio and resistance to temperature make it an indispensable material for manufacturing components such as engine parts, wings, and airframes.

- In the medical industry, its biocompatibility lends itself to the production of surgical instruments, orthopedic implants like hip balls and sockets, dental implants, and even wheelchairs.

- The automotive industry leverages this robust metal in creating parts that must withstand high stress and strain, such as connecting rods and valves.

Titanium’s versatile properties endow it with extensive industrial applicability – making precision-machined titanium parts pivotal in driving advancements within these key sectors.

Choosing a Reliable Precision CNC Machining Service

Selecting the right provider for precision CNC machining services can be a daunting task. The criteria to consider when choosing such services include not only cost-effectiveness but also factors related to reliability, expertise, experience and the type of technology utilized. A reliable provider will have built a strong reputation over years of consistent service, offering positive customer testimonials as evidence of their quality work. Their team would possess deep expertise in handling various materials, especially titanium which requires specific techniques due to its unique properties. Further, an updated understanding of emerging technologies, including 5-axis CNC machines, becomes essential for providers to maintain strict accuracy. Examples of companies excelling in these aspects are some industry-leaders who prioritize continuous learning and advancement in addition to customer satisfaction.

- Reputation: Reviews or references can provide insight into the supplier’s credibility.

- Expertise: Ensure that the provider has vast experience working with titanium parts.

- Technology: Leading-edge machinery like 5-axis CNC machines should be used for better accuracy.

Related Posts

- Using CNC Machining to Fabricate Lightweight Metal and Remove Chrome From Metal( cnc machining services china Dana)

CNC (Computer Numerically Controlled) machining is an essential process in the manufacturing domain. With its precision, adaptability, and extensive applications, many industries rely on it for fabricating highly complex parts…

- Efficient Ways to Remove Chrome from Lightweight Metal Using CNC Machining(how to remove chrome from metal Sid)

The world of manufacturing and production has evolved significantly in recent years, largely due to the advancement in technology. Today, Computer Numeric Control (CNC) machining plays a crucial role in…

- CNC Machining: How to Remove Chrome from Lightweight Metal( cantilever snap joint Riva)

CNC machining is an automated process in the manufacturing industry that has dramatically shifted traditional processes. It facilitates tools like grinders, lathes, mills, and routers controlled by computer numerical control…