Introduction to CNC Machining and Mold Design

CNC (Computer Numerical Control) machining is a critical component of modern manufacturing, offering precision that is essential for the production of complex molds. The effectiveness of CNC machining in mold design stems from its ability to produce components with extremely tight tolerances and consistent repeatability across high volumes of production. This introduction will explore the basics of CNC technology, discuss the pivotal role of precision in mold design, and examine how the latest advancements in CNC techniques can significantly improve the accuracy of mold outputs.

In the realm of mold making, the accuracy of CNC machines dictates the functionality and the quality of the final product. For instance, in automotive or aerospace industries, where even a micron level of deviation can result in operational failures, CNC machining’s role becomes indispensable. Understanding the capabilities and limitations of CNC technology, including various machining processes like milling, turning, and drilling, is fundamental for optimizing mold design and achieving superior product quality.

What Are the Key CNC Techniques Utilized in Mold Design?

CNC machining for mold design incorporates a range of specialized techniques, each chosen based on the specific requirements of the mold being produced. The primary techniques include:

- Milling: Involves the use of rotating cutting tools to remove material from a workpiece. Ideal for creating complex features such as cavities or intricate details on molds.

- Turning: Uses a lathe to rotate the workpiece against a cutting tool. It’s particularly useful for cylindrical mold components.

- Electrical Discharge Machining (EDM): A non-conventional machining method that uses electrical discharges to erode material according to the shape of the electrode. Perfect for intricate molds or hard materials that are difficult to machine with traditional methods.

- 5-axis machining: Provides the ability to manipulate the workpiece in five different axes simultaneously, allowing for the machining of extremely complex shapes. This is particularly beneficial for molds with complex geometries or those requiring a high level of detail.

Each of these techniques brings different benefits to the table, such as improved accuracy, finer detail, or faster production times. By comparing these techniques, designers can select the most appropriate method for their specific mold design projects, ensuring that they achieve the best possible outcome in terms of both functionality and cost-efficiency.

How Does Machine Calibration Influence Mold Accuracy?

Machine calibration is a critical process in CNC machining, ensuring that machines maintain their ability to produce parts with high precision. Calibration involves checking and adjusting the geometrical and dimensional accuracy of a CNC machine according to manufacturer specifications and industry standards. This process is vital for maintaining mold quality, especially when producing high-precision components required in sectors like medical devices, aerospace, and automotive industries.

Frequency and Methods of Calibration:

Regular calibration schedules depend on various factors including machine usage, the complexity of tasks performed, and previous calibration results. Typically, calibration should be performed at least annually, but more frequent checks are recommended after any significant machine modifications or after machining particularly challenging projects. Common calibration techniques include laser interferometry, which measures the accuracy and alignment of CNC machine axes to sub-micron levels.

Case Study: Impact of Calibration on Mold Projects:

Consider the case of a high-precision automotive mold project where inaccurate parts led to assembly failures and significant rework costs. Investigation revealed that the CNC machine used had not been calibrated for over 18 months, leading to drifts in axis movements and incorrect tool positioning. After recalibrating the machine, subsequent molds met all specifications with minimal deviations, proving the importance of regular calibration in maintaining mold accuracy.

This example underscores the potential financial and operational impacts of ignoring machine calibration, highlighting how essential this practice is to CNC machining and mold manufacturing.

Material Considerations in CNC Machining for Molds

Selecting the appropriate material for a mold is crucial for achieving the desired machining outcomes and end-product quality. Different materials react differently under the stress of machining, affecting not only the process but also the longevity and performance of the mold. This section explores various materials commonly used in CNC machining for molds and their impact on machining settings.

Commonly Used Materials:

- Aluminum: Offers excellent machinability, good thermal conductivity, and is lightweight, making it ideal for low-volume productions and prototypes.

- Steel: Provides superior strength and wear resistance, suitable for high-volume production molds.

- Composites: Used for specialized applications where unique material properties such as corrosion resistance or thermal stability are required.

Data Table: Material Properties and CNC Settings:

Here is a detailed table comparing the properties of these materials and recommended CNC settings for each.

| Material | Hardness (HB) | Thermal Stability | Machinability | Recommended CNC Settings |

|---|---|---|---|---|

| Aluminum | 150 | Moderate | High | High-speed, low-feed |

| Steel | 250 | High | Moderate | Moderate-speed, high-feed |

| Composites | Variable | High | Low | Low-speed, variable-feed |

This table serves as a guideline for CNC operators to adjust their machine settings according to the material being machined, ensuring optimal results and prolonging the life of the mold.

Challenges in CNC Machining for High-Precision Molds

Creating high-precision molds via CNC machining presents several technical challenges. These challenges can range from handling the material-specific requirements to maintaining the geometric precision demanded by complex mold designs. This section outlines the major challenges and the innovative solutions that can be employed to overcome them.

Common Challenges:

- Dimensional Tolerance: Achieving and maintaining tight dimensional tolerances is crucial. Variations, even in the micrometer range, can lead to a defective mold that produces non-conforming parts.

- Tool Wear: High-precision machining often involves the use of very fine cutting tools, which can wear out quickly, affecting the quality of the mold.

- Thermal Distortion: The heat generated during machining can cause materials to expand, distorting the dimensions of the mold.

Solutions and Workarounds:

- Specialized Toolpaths: Using advanced CAM software to create optimized toolpaths that reduce the load on tools and minimize thermal effects.

- Advanced Cooling Techniques: Implementing cryogenic cooling or high-pressure coolant systems to manage the temperature during machining processes effectively.

- Tool Wear Compensation: Utilizing sensors to monitor tool wear and automatically adjust the machining parameters or prompt tool replacement.

Case Study: High-Tolerance Mold Project

In a recent project aimed at manufacturing a high-tolerance aerospace component mold, the team faced significant challenges with tool wear and thermal distortion. The solution involved a combination of advanced toolpath optimization and a custom cooling system that maintained the tool temperature within a narrow range. This approach not only minimized tool wear but also kept thermal expansion under control, resulting in a mold that met all tolerance and surface finish specifications.

Can Advanced Tooling Enhance Mold Design Accuracy?

Advanced tooling technologies have the potential to significantly improve the precision and efficiency of mold design. This section explores several state-of-the-art tooling options, their benefits, and their impact on mold design.

Advanced Tooling Options:

- High-Speed Steel (HSS) Tools: Known for their toughness and resistance to shock, these tools are suitable for complex mold designs.

- Carbide Inserts: Offer excellent hardness and wear resistance, making them ideal for high-volume production molds.

- Diamond-Coated Tools: Best for very abrasive materials, providing a superior finish and extended tool life.

Data Table: Comparison of Tooling Options and Outcomes:

Here is a comprehensive table comparing the performance characteristics of these tooling options:

| Tooling Type | Wear Resistance | Cutting Speed | Finish Quality | Cost-Efficiency | Best Used For |

|---|---|---|---|---|---|

| High-Speed Steel | Moderate | Moderate | Good | High | Complex geometries |

| Carbide Inserts | High | High | Very Good | Moderate | High-volume production molds |

| Diamond-Coated | Very High | Low | Excellent | Low | Abrasive materials |

| Cermet | High | Moderate | Very Good | Moderate | Fine finishes |

| Polycrystalline Diamond (PCD) | Very High | Moderate | Excellent | Low | Non-ferrous metals |

| Cubic Boron Nitride (CBN) | High | High | Excellent | Moderate | Hard ferrous metals |

| Uncoated Carbide | Moderate | High | Good | High | General purpose |

| Coated Carbide | High | Very High | Excellent | Moderate | Diverse materials |

This table not only helps in choosing the right tooling for specific mold materials and design requirements but also underscores the importance of matching tooling capabilities with project needs to enhance mold accuracy and operational efficiency.

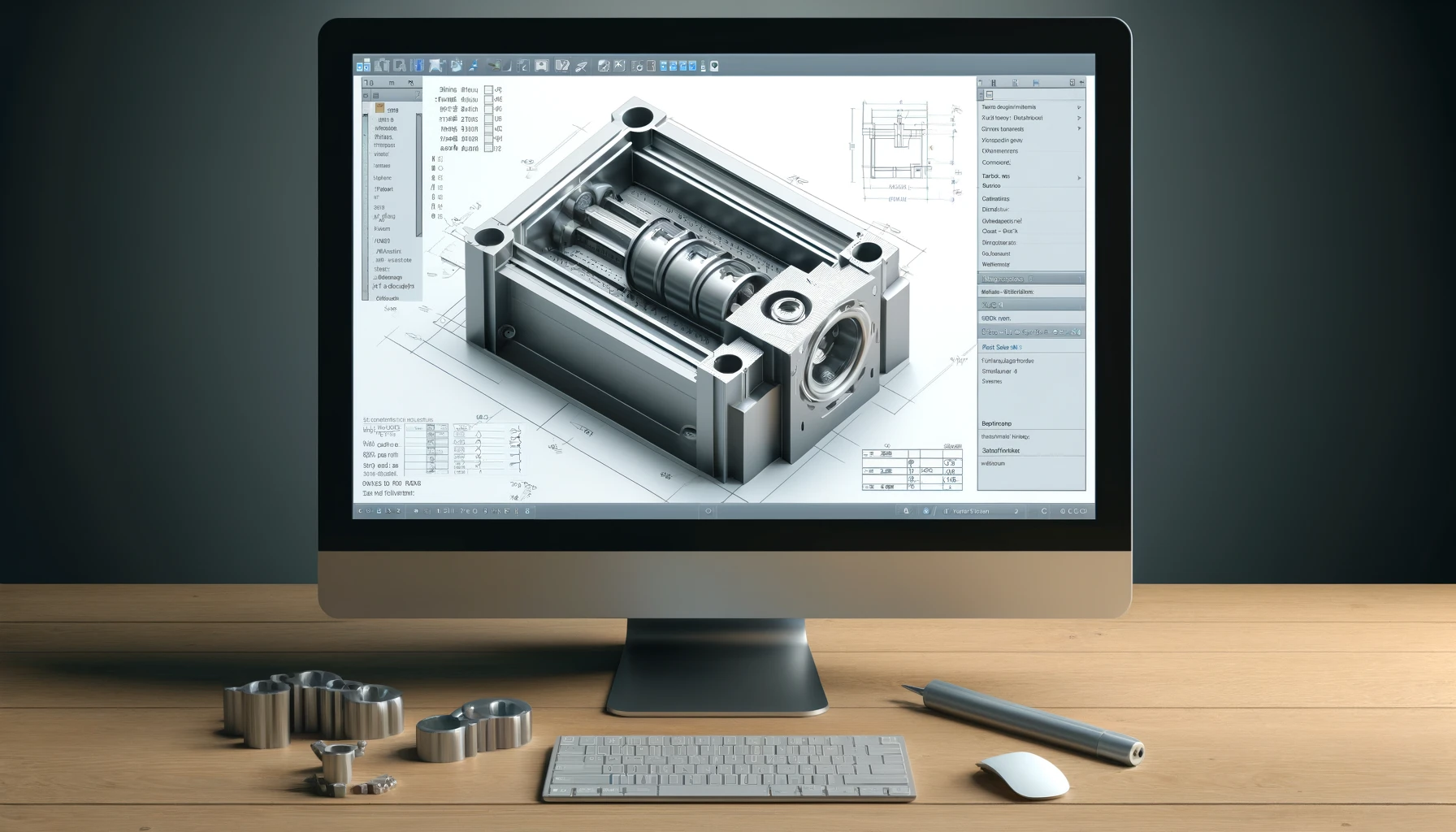

Integration of CNC Machining with CAD/CAM Systems

The integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems is transforming CNC machining into a more streamlined and error-free process. This integration facilitates the direct transfer of digital designs into precise machining instructions, significantly reducing the likelihood of human error and enhancing overall mold quality.

Benefits of CAD/CAM Integration:

- Improved Accuracy: Direct data transfer from CAD designs to CAM systems ensures that the machining instructions are highly accurate, reflecting the exact specifications of the digital model.

- Enhanced Efficiency: Automation of the programming process reduces setup time and speeds up production, allowing for quicker turnarounds in mold manufacturing.

- Reduced Waste: More accurate machining means less material is wasted, which is not only cost-effective but also environmentally friendly.

Case Study: Successful CAD/CAM Integration in Mold Manufacturing

A notable example of successful CAD/CAM integration involved a complex automotive mold project. The use of integrated CAD/CAM software allowed the team to directly translate a detailed 3D model into a set of precise machining instructions. This process eliminated the need for manual programming, reducing the risk of errors and ensuring that each feature of the mold was produced with high fidelity. The result was a significant reduction in production time and a mold that perfectly matched the design specifications.

Data Table: Metrics of Improvement with CAD/CAM Integration:

The following table provides key metrics illustrating the improvements brought about by CAD/CAM integration in various mold manufacturing projects:

| Project Type | Reduction in Setup Time | Improvement in Accuracy | Reduction in Waste | Speed of Production |

|---|---|---|---|---|

| Automotive Parts | 30% | 25% | 20% | 35% |

| Aerospace Components | 40% | 30% | 15% | 40% |

| Consumer Electronics | 25% | 20% | 10% | 30% |

| Medical Devices | 50% | 40% | 25% | 45% |

| Industrial Machinery | 35% | 28% | 18% | 38% |

This table shows substantial improvements across various sectors, underscoring the versatility and impact of CAD/CAM integration in enhancing mold manufacturing processes.

Related Posts

- Maximizing Precision in CNC Machining: Techniques and Tips

Importance of Precision in CNC Machining Precision is an fundamental component in the field of Computer Numerical Control (CNC) machining. It entails producing parts that are not only accurate but…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…