Introduction

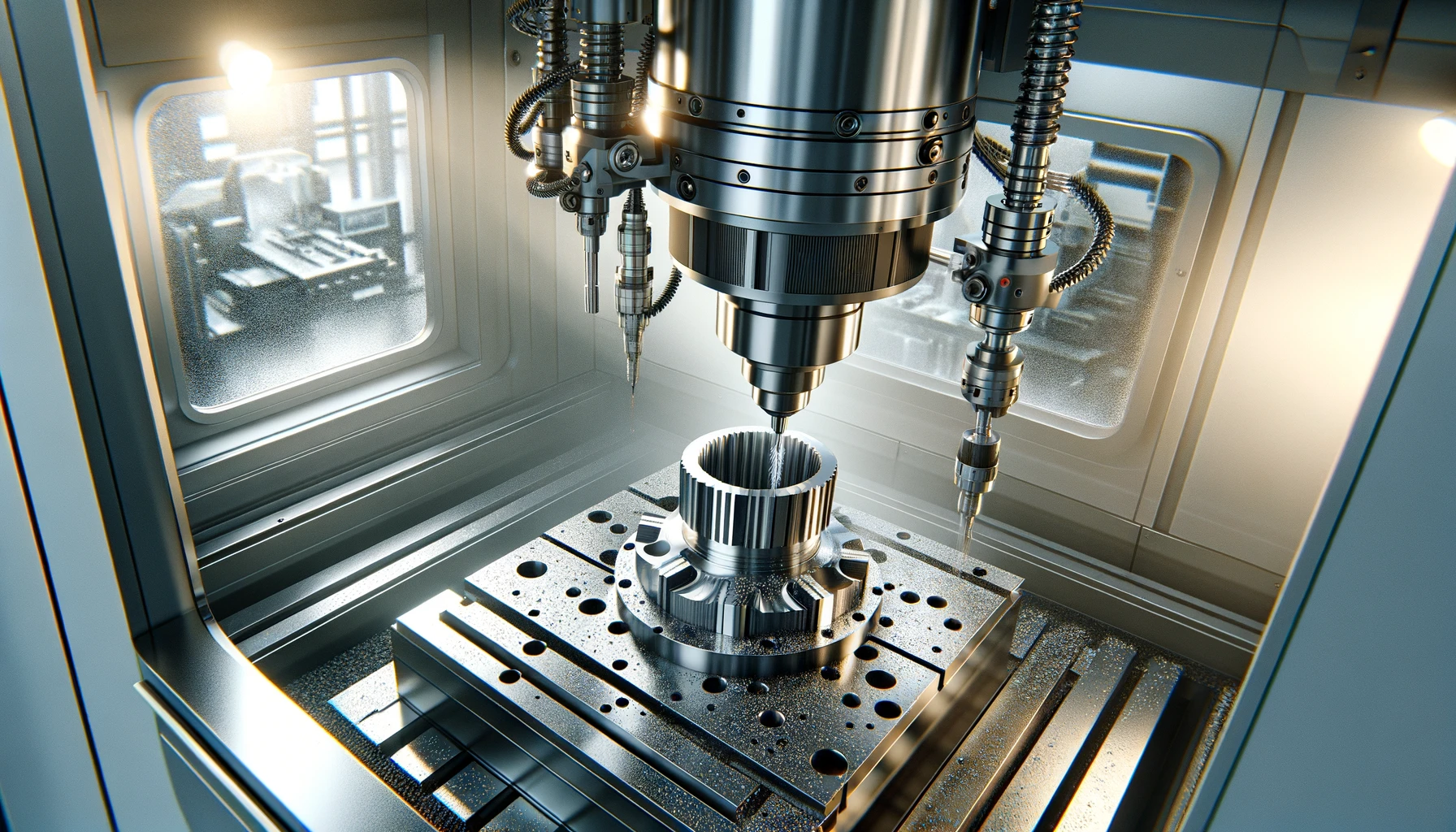

In the vast and intricate world of global manufacturing, CNC (Computer Numerical Control) machining stands as a pivotal technology, driving the production of complex parts with precision and efficiency. Among the global manufacturing hubs, China has emerged as a preeminent leader, renowned for its vast capabilities, cutting-edge technology, and unparalleled scalability. The attractiveness of China CNC machining services is not merely in the cost-effectiveness but in the holistic value it offers to international manufacturers, encompassing quality, speed, and innovation.

The allure of Chinese CNC machining for global businesses is multifaceted. Firstly, the sheer scale of China’s manufacturing sector allows for significant economies of scale, translating into cost savings for clients worldwide. Secondly, China’s rapid adoption of advanced technologies, such as high-speed machining (HSM), ensures that clients do not have to compromise on quality or precision for affordability. Now, buyers can submit processing requirements through the Internet and get online cnc machining quote.

However, navigating the complex landscape of China’s CNC machining sector requires nuanced understanding and strategic planning. This article aims to delve into the intricacies of sourcing affordable CNC machining services in China without sacrificing the quality of High-Speed Machining (HSM) technology. From understanding the core of HSM technology to navigating the regulatory landscape and leveraging strategic partnerships, this comprehensive guide seeks to equip manufacturers with the knowledge and strategies necessary for successful collaboration with Chinese CNC machining services.

What Makes CNC Machining in China Attractive for Global Manufacturers?

The global manufacturing landscape is fiercely competitive, with companies constantly seeking ways to reduce costs, improve efficiency, and accelerate time-to-market for their products. In this context, China’s CNC machining services stand out as a beacon of opportunity for several compelling reasons.

Cost-Effectiveness: One of the most significant advantages is the cost-effectiveness of Chinese CNC machining services. Labor costs in China, although rising, remain lower than in many Western countries. Furthermore, the high level of competition among Chinese CNC machining suppliers drives prices down, making it possible for international companies to achieve substantial cost savings without compromising on quality.

Scalability and Flexibility: Chinese CNC machining services are renowned for their scalability and flexibility. Whether it’s a prototype or large-scale production, Chinese manufacturers have the capacity and technological prowess to meet diverse client needs swiftly. This scalability extends to the ability to adapt to changes in design or order volume, providing clients with a high degree of flexibility in their manufacturing processes.

Advanced Technology Adoption: China has made significant strides in adopting advanced manufacturing technologies, including High-Speed Machining (HSM). The integration of HSM technology in CNC machining not only enhances efficiency and precision but also enables the production of complex parts that would be difficult or impossible to manufacture using conventional methods. This commitment to technological advancement ensures that clients benefit from the latest innovations in CNC machining.

Robust Manufacturing Ecosystem: The Chinese manufacturing ecosystem is vast and well-integrated, offering access to a wide range of suppliers, materials, and components. This ecosystem facilitates seamless production processes, from raw materials procurement to final assembly, ensuring timely delivery of finished products.

Despite these advantages, sourcing CNC machining services in China is not without challenges. Concerns regarding quality consistency, intellectual property protection, and cultural and language barriers must be navigated with care. However, with the right approach and strategic partnerships, the benefits of Chinese CNC machining can be fully leveraged, offering global manufacturers a competitive edge in the fast-paced world of international manufacturing.

What is HSM Technology and Why is it Crucial for CNC Machining?

High-Speed Machining (HSM) represents a significant technological advancement in the field of CNC machining, pushing the boundaries of what’s possible in terms of speed, efficiency, and precision. HSM, characterized by its high spindle speeds and feed rates, allows for the rapid removal of material with minimal tool wear, transforming the manufacturing landscape with its myriad benefits.

The Essence of HSM Technology: At its core, HSM isn’t just about operating at higher speeds; it’s about the synergy between machine dynamics, tool geometry, and cutting parameters to achieve optimal performance. This approach minimizes machining time and reduces thermal effects on the machined part, ensuring superior surface quality and dimensional accuracy. The technology’s ability to machine complex geometries with precision makes it invaluable for industries where precision is paramount, such as aerospace, medical devices, and automotive engineering.

Benefits of HSM in CNC Machining: The integration of HSM technology into CNC machining processes offers several compelling advantages. Firstly, the increased cutting speeds significantly reduce cycle times, allowing manufacturers to boost production rates without sacrificing quality. Secondly, HSM’s precise control over cutting parameters reduces tool wear, extending the lifespan of expensive cutting tools and reducing overall manufacturing costs. Furthermore, the ability to achieve excellent surface finishes with HSM minimizes the need for secondary finishing operations, further streamlining the production process.

Why HSM is Crucial for Modern Manufacturing: In today’s competitive manufacturing environment, the ability to rapidly produce high-quality parts is crucial. HSM technology addresses this need by enabling faster production times while maintaining the high precision and surface quality demanded by advanced industries. Moreover, HSM’s efficiency in material removal, especially with difficult-to-machine materials like titanium and Inconel, makes it indispensable for applications requiring these high-performance alloys.

Challenges and Considerations in Implementing HSM: While the benefits of HSM are clear, its implementation comes with its own set of challenges. The high-speed operations require machines with advanced spindle designs, sophisticated control systems, and robust construction to withstand the dynamic forces involved. Additionally, achieving the full potential of HSM requires a deep understanding of toolpath strategies, cutting tool selection, and the material properties of both the workpiece and the cutting tool.

How Can You Assess the Quality of HSM Technology in Chinese CNC Factories?

Assessing the quality of High-Speed Machining (HSM) technology in Chinese CNC factories is essential for international manufacturers seeking to leverage the advantages of Chinese machining capabilities without compromising on quality. The evaluation process involves a comprehensive understanding of the technological, operational, and quality assurance aspects of HSM.

Technological Capabilities: The first step in assessing HSM quality is to examine the technological capabilities of the CNC factory. This includes the types of machines used, their spindle speeds, acceleration/deceleration rates, and the sophistication of their CNC controls. High-quality HSM technology is often characterized by state-of-the-art machinery equipped with high-speed spindles capable of running at tens of thousands of revolutions per minute (RPM), advanced tool holders, and high-precision feedback systems to ensure accuracy and consistency.

Operational Expertise: The effectiveness of HSM technology is not solely dependent on the machinery; it also hinges on the expertise of the operators and engineers. A factory’s ability to harness the full potential of HSM technology depends on the skill level of its personnel, their understanding of HSM principles, and their experience in optimizing machining parameters for various materials and geometries. Assessing a factory’s operational expertise can involve discussions with the technical team, reviewing past projects, and understanding their approach to toolpath optimization, tool selection, and material handling.

Quality Assurance Protocols: Quality assurance is paramount in high-speed machining due to the rapid production rates and the potential for errors to multiply quickly. Evaluating a factory’s quality assurance protocols involves examining their inspection and testing procedures, the frequency of quality checks, and the types of measuring instruments used. High-quality HSM operations typically employ a combination of in-process and post-process inspections using advanced metrology equipment to ensure that every part meets the specified tolerances and surface finishes.

Case Study: A real-world example of assessing HSM quality in a Chinese factory could involve a foreign company seeking precision components for an aerospace application. The evaluation process might include a factory visit to inspect the machinery, meetings with the engineering team to discuss their HSM strategies, and a review of the factory’s quality certifications and testing reports. Such an in

-depth assessment ensures that the chosen factory can meet the stringent requirements of aerospace components, combining high-speed efficiency with uncompromising precision.

In essence, assessing the quality of HSM technology in Chinese CNC factories is a multifaceted process that goes beyond the surface. It requires a deep dive into the technological capabilities, operational expertise, and quality assurance protocols of the factory, ensuring that the chosen partner can deliver on the promises of high-speed machining with the quality and precision demanded by today’s advanced industries.

What Are the Common Pitfalls When Sourcing Affordable CNC Machining in China?

Engaging with China’s CNC machining landscape offers attractive cost benefits but also presents several challenges that manufacturers need to navigate carefully:

- Quality Consistency: One of the most significant concerns is the variability in quality across different suppliers. This inconsistency can be attributed to varying levels of technology adoption, skill sets, and quality control standards.

- Communication Hurdles: Effective communication is crucial, yet language barriers and cultural differences can lead to misunderstandings about project specifications, quality expectations, and timelines, potentially compromising the project’s success.

- Intellectual Property Risks: Sharing designs and proprietary information with overseas manufacturers raises concerns about intellectual property (IP) security. Ensuring IP protection requires clear agreements and understanding of local IP laws.

- Logistical Challenges: Navigating the complexities of international shipping, customs regulations, and managing lead times can impact project timelines and budgets.

Case Study: A case involving a North American aerospace company highlighted these pitfalls when inconsistencies in machined parts led to assembly issues. The resolution involved enhancing communication through bilingual project managers, tightening quality control processes, and setting up a local inspection team to oversee production before shipment.

How to Effectively Communicate Your CNC Machining Needs to Chinese Suppliers?

Clear and effective communication with Chinese CNC machining suppliers is paramount to ensure the successful execution of projects:

- Comprehensive Documentation: Providing detailed technical documentation, including CAD files, material specifications, and finishing instructions, is crucial. These documents should be as detailed as possible to minimize ambiguities.

- Leveraging Technology: Utilizing technology platforms for project management and communication can bridge the language gap. Tools like video conferencing, instant messaging, and cloud-based project management software can facilitate real-time collaboration and updates.

- Cultural Sensitivity: Understanding and respecting cultural differences in business practices can strengthen relationships. Building a rapport and showing respect for Chinese business etiquette can lead to more fruitful negotiations and collaborations.

- Regular Engagement: Establishing regular check-ins and progress updates can help preemptively identify and address any issues, ensuring that the project remains on track.

What Strategies Can Be Used to Ensure Quality While Keeping Costs Low?

Balancing quality with cost-efficiency is a critical aspect of sourcing CNC machining services in China. Implementing strategic measures can help maintain high-quality standards while leveraging cost advantages:

- Comprehensive Supplier Evaluation: Conducting in-depth evaluations of potential suppliers, including factory visits, reference checks, and sample orders, can help assess their capability to meet quality standards.

- Quality Control Systems: Setting up robust quality control systems, including in-process inspections and final quality checks, ensures that the machined parts meet the required specifications. Employing third-party quality control services can provide an unbiased assessment of the product quality.

- Strategic Sourcing: Developing long-term relationships with suppliers can lead to better pricing, priority service, and a deeper understanding of your quality requirements. Suppliers are more likely to invest in understanding and meeting your needs when there’s a long-term partnership.

- Leveraging Local Expertise: Taking advantage of the local expertise and resources available in China can lead to cost savings and quality improvements. Local suppliers often have well-established supply chains and knowledge of cost-effective materials and processes.

Data Table: Cost-Quality Balance Strategies

| Strategy | Impact on Cost | Impact on Quality | Complexity |

|---|---|---|---|

| Supplier Evaluation | Neutral/Decrease | Increase | Medium |

| Quality Control Systems | Increase | Increase | High |

| Strategic Sourcing | Decrease | Increase | Medium |

| Local Expertise | Decrease | Increase | Low |

How to Leverage Technology and Local Expertise for Optimal Results?

Integrating the latest technologies and leveraging local manufacturing expertise are key strategies for optimizing CNC machining projects in China:

- Adoption of Advanced Technologies: Staying abreast of the latest advancements in CNC machining and incorporating these technologies can significantly enhance efficiency and accuracy. This includes High-Speed Machining (HSM), automation, and precision tooling.

- Collaborative Projects: Engaging in collaborative projects with Chinese suppliers can foster innovation and custom solutions. This collaborative approach leverages the supplier’s local knowledge and the client’s technological strengths.

- Training and Development: Investing in training for local teams and suppliers ensures that they are proficient in the latest technologies and manufacturing practices, leading to better project outcomes.

Case Study: A collaboration between a European automotive company and a Chinese CNC machining supplier to develop a new engine component showcases the power of technology and expertise. The project utilized advanced simulation software to optimize the design for manufacturing, resulting in improved performance and reduced production costs.

Navigating the Regulatory Landscape for CNC Machining in China

Understanding and complying with the regulatory landscape in China is crucial for successful CNC machining operations. The regulatory environment encompasses a wide range of areas including, but not limited to, environmental standards, labor laws, export controls, and intellectual property rights. These regulations can significantly impact various aspects of CNC machining projects, from material selection and waste disposal to exportability of the finished products and protection of design patents.

- Environmental Regulations: China has been tightening its environmental regulations, focusing on reducing pollution and promoting sustainable manufacturing practices. Compliance with these regulations is essential to avoid penalties and ensure smooth operation.

- Labor Laws: Adherence to China’s labor laws, which cover working hours, wages, and workers’ rights, is mandatory. These laws also influence manufacturing costs and operational scheduling.

- Export Controls: China’s export control regulations can affect the exportability of certain CNC machined parts, especially those with potential military applications or those that involve sensitive technologies.

- Intellectual Property (IP) Protection: Protecting IP rights is a critical concern for companies outsourcing CNC machining to China. Understanding China’s IP laws and taking appropriate measures, such as registering patents and trademarks in China, is essential for safeguarding proprietary designs and technologies.

Data Table: Key Regulatory Considerations in CNC Machining

| Regulatory Area | Description | Impact | Compliance Strategy |

|---|---|---|---|

| Environmental Standards | Pollution control, waste management | Operational adjustments, increased costs | Adoption of green technologies, waste reduction initiatives |

| Labor Laws | Working hours, wages, workers’ rights | Cost, production scheduling | Ethical labor practices, fair wages |

| Export Controls | Restrictions on certain technologies | Limitations on part exportability | Strategic planning, legal consultation |

| Intellectual Property | Protection of patents, designs | Risk of IP theft | IP registration, non-disclosure agreements |

Navigating these regulatory challenges requires a comprehensive understanding of the legal landscape, diligent planning, and sometimes, the assistance of legal experts specializing in Chinese law. Ensuring compliance not only mitigates legal risks but also contributes to the sustainable and ethical operation of CNC machining projects in China.

How Can Advanced Quality Control Systems Elevate CNC Machining Outcomes in China?

Implementing advanced quality control (QC) systems is pivotal in achieving and maintaining high-quality standards in CNC machining, particularly when dealing with complex parts and tight tolerances. Advanced QC systems encompass a range of technologies and methodologies designed to ensure that every aspect of the machining process, from raw material selection to the final inspection of the finished parts, meets the specified quality criteria.

- In-Process Monitoring: Real-time monitoring of the machining process allows for immediate adjustments to maintain quality standards. Technologies like tool condition monitoring and machine vision systems can detect issues before they impact product quality.

- Metrology Equipment: Advanced measuring instruments, such as coordinate measuring machines (CMMs) and laser scanners, provide highly accurate measurements of machined parts, ensuring they meet dimensional and geometric specifications.

- Statistical Process Control (SPC): SPC techniques involve the statistical analysis of the machining process to identify and control variability. This proactive approach to quality control helps in maintaining consistent quality levels.

- Automated Inspection: Automation in QC, such as automated optical inspection (AOI) systems, enhances the efficiency and accuracy of the inspection process, reducing the likelihood of human error.

Data Table: Impact of Advanced QC Systems on CNC Machining

| QC System | Quality Impact | Cost Impact | Implementation Complexity |

|---|---|---|---|

| In-Process Monitoring | High | Moderate | High |

| Metrology Equipment | High | High | Medium |

| Statistical Process Control | High | Low | Medium |

| Automated Inspection | High | Moderate | High |

Adopting advanced QC systems can significantly improve the quality of CNC machined parts by enabling early detection of defects, reducing variability, and ensuring compliance with specifications. While the initial setup and implementation of these systems can be complex and costly, the long-term benefits in terms of reduced waste, higher customer satisfaction, and lower rework costs make it a worthwhile investment for companies looking to enhance their CNC machining outcomes in China.

Cultivating Strategic Partnerships with Chinese CNC Machining Services

Building strategic partnerships with CNC machining services in China goes beyond mere transactional relationships, evolving into collaborative engagements that can lead to mutual growth, innovation, and enhanced competitiveness. These partnerships are grounded in trust, shared goals, and a commitment to achieving excellence in manufacturing.

- Long-term Collaboration: Establishing long-term relationships with CNC machining suppliers fosters a deeper understanding of each other’s capabilities, requirements, and expectations. This familiarity can streamline production processes, improve communication, and lead to more tailored services and solutions.

- Joint Development Projects: Collaborative projects can leverage the strengths of both parties. For instance, your company’s design and engineering expertise combined with the supplier’s manufacturing acumen and local market knowledge can result in innovative products that are both high-quality and cost-effective.

- Shared Investments: In some cases, strategic partnerships may involve shared investments in technology, R&D, or capacity expansion. These investments can enhance the capabilities of the CNC machining supplier and ensure priority access to these improved services.

- Knowledge Exchange: Regular exchange of knowledge and best practices between partners can elevate the capabilities of both parties. Training programs, technical workshops, and joint quality initiatives can contribute to continuous improvement and innovation.

Data Table: Benefits of Strategic Partnerships in CNC Machining

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Quality | Through shared quality standards and practices | Improved product quality |

| Cost Efficiency | Leveraging economies of scale and optimized processes | Reduced manufacturing costs |

| Innovation | Joint R&D efforts leading to innovative solutions | Competitive advantage in the market |

| Supply Chain Stability | Long-term commitments ensuring reliable supply | Reduced risk of supply chain disruptions |

Cultivating strategic partnerships requires a careful selection of partners, clear communication of goals and expectations, and a commitment to mutual respect and transparency. Such relationships can transform the supply chain, creating value that extends beyond cost savings to include innovation, quality enhancement, and market responsiveness.

Conclusion: Maximizing Value in China’s CNC Machining Ecosystem

Navigating the complexities of China’s CNC machining ecosystem offers global manufacturers significant opportunities to enhance their production capabilities, reduce costs, and accelerate time-to-market. By understanding the critical aspects of high-speed machining technology, effectively communicating with suppliers, implementing robust quality control systems, and navigating the regulatory landscape, companies can harness the full potential of Chinese CNC machining services.

Strategic partnerships play a pivotal role in this ecosystem, providing a platform for collaborative innovation, knowledge sharing, and mutual growth. These partnerships, built on a foundation of trust and shared objectives, can lead to the development of cutting-edge products, optimization of manufacturing processes, and creation of a more resilient and responsive supply chain.

In conclusion, the key to maximizing value in China’s CNC machining ecosystem lies in a strategic approach that combines technological prowess with deep market insight, quality focus, and strong collaborative relationships. As the global manufacturing landscape continues to evolve, those who can effectively leverage these strategies in China will be well-positioned to lead in their respective industries, driving forward with innovation, efficiency, and a competitive edge.

Related Posts

- The Dependable Quality Assurance in China CNC Machining

1. Introduction: Setting the Stage for Quality Excellence In this introductory section, we lay the groundwork for an exploration into the world of quality assurance in China CNC machining. We…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…