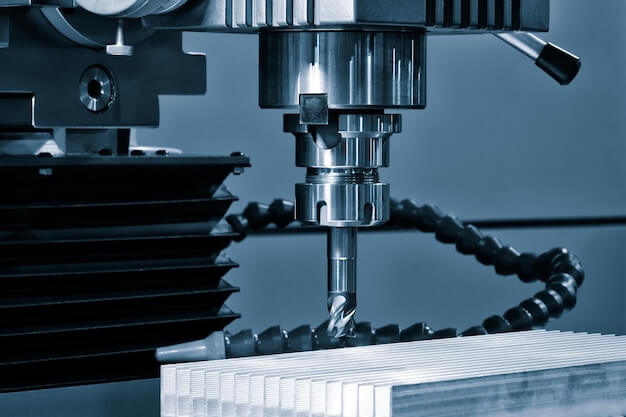

CNC Machining and Material Importance in Manufacturing

Computer Numerical Control (CNC) machining is a manufacturing process that leverages computers to control machine tools including lathes, mills and grinders among others. Its usage in industries is primarily for the creation of complex three-dimensional parts through subtractive methods where material is taken away, as opposed to additive ones like 3D printing. In CNC machining, selecting the right material has paramount importance due to its impact on the final product’s quality, strength, finish, resistance to wear, and overall lifespan. Incorrect choice could lead not just to intended product failure but also damage to the processing machinery itself. Consequently, materials like Inconel and Monel have been widely utilized given their ideal characteristics for certain applications.

Understanding Inconel

Inconel is a type of superalloy noted for its exceptional resistance to extreme temperatures and corrosion. Formulated from a robust blend of nickel, chromium, and oftentimes iron, it possesses characteristics that make it particularly suited to challenging environments like those found in engineering applications on land, sea, air, or even space.

- Durability:Inconel is known for its toughness and long-lasting nature, able to maintain its structural integrity under severe conditions.

- Heat Resistance: The alloy can withstand intense heat due to its distinctive capability to form a stable, adherent oxide layer when heated. This protective barrier prevents further attack by heat or corrosive elements.

- Corrosion Resistant:A unique trait of Inconel lies in its resistivity against oxidation and chemical-based degradation, making it highly versatile in varied domains such as maritime and chemical processing industries.

Despite its benefits, the use of Inconel is not without drawbacks. For instance, in CNC machining, its high work-hardening rate makes it difficult to machine and requires specialized techniques and equipment. Furthermore, Inconel products tend to be more expensive than other materials due to their complex manufacturing process. However, this high cost often proves justified considering the durability and quality offered by the metal.

Understanding Monel in CNC Machining

Monel is a versatile material for CNC machining, offering excellent corrosion resistance, high strength, and good machinability. It is commonly used in marine and chemical processing applications due to its resistance to corrosive environments.

Comparing Inconel with Monel

In a comparison between Inconel and Monel, each material has properties that distinguish it in the sphere of CNC machining. Inconel, a superalloy composed of nickel-chromium, is known for its excellent resistance to oxidation and corrosion even at high temperatures, making it an ideal selection for applications involving extreme environments. On the other hand, Monel – primarily made up of nickel and copper – features exceptional resistance to alkalis and acids, along with impressive thermal conductivity.

As an illustration of their differences let’s consider a typical industrial scenario utilising heat exchanges. Heat exchangers often face chemical exposure and operate under varying temperature conditions. In this setting, if the environment involves high-temperature oxidative conditions, Inconel could be the preferable choice due to its superior capacity to resist oxidation. However, if the heat exchanger requires better thermal conductivity or works within more corrosive but not necessarily high-temperature situations (such as those with strong acids), then Monel may offer enhanced performance.

Making An Informed Decision: Tips for Choosing between Inconel and Monel

When it comes to selecting the right material for CNC machining projects, understanding the properties of each option is crucial. Not all materials perform equally under varying conditions and applications, thus necessitating a careful consideration based on several factors.

- Inconel: This nickel-chromium-based superalloy withstands extreme environments due to its resistance to oxidation and corrosion. If your project involves exposures to high-temperature circumstances or corrosive media, Inconel might be your best choice.

- Monel: Another member of the nickel alloys, Monel has excellent corrosion resistance in hydrofluoric acid and many salt solutions, making it ideal for certain chemical-related industries. Its strength remains consistent at low temperatures, offering reliability in cold conditions.

Paying attention to these specific strengths and weaknesses can guide you toward deciding which material – Inconel or Monel – will serve your project most optimally. Remember that aspects like cost-efficiency, accessibility, machinability also hold importance while finally settling upon the particular material.

Related Posts

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- CNC Machining for Consumer Electronics: Material Selection for Heat Dissipation

Introduction to CNC Machining in Consumer Electronics CNC machining stands as a pivotal technology in the manufacturing of consumer electronics, offering precision and efficiency in producing components. This process involves…

- The Benefits of Multi-Material CNC Machining for Complex Parts

Introduction to CNC Machining and Multi-Material Machining CNC (Computer Numerical Control) machining stands as a cornerstone in the manufacturing industry, enabling the precise creation of complex parts through automated control…