CNC Machining Applications and the Role of Molybdenum

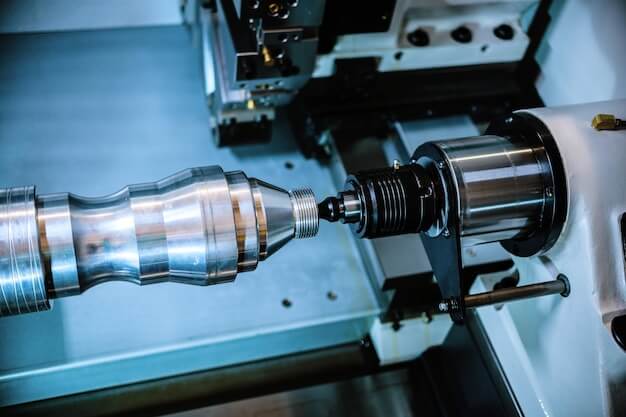

Computer Numerical Control (CNC) machining is a revolutionary process transforming raw materials into intricate components. This cutting-edge approach automates control of machining tools, streamlining operations across various industries such as automotive, aerospace, and electronics. Complex parts can be produced swiftly with high precision and accuracy, eliminating potential human errors.

China Online CNC Machining Service

A key component of CNC applications is the matter of material selection. Here, molybdenum enters the spotlight. Known for its exceptional strength and resistance to heat, it poses an attractive choice in harsh operational conditions. Its durability and robustness ensure that no compromise on quality or efficiency prevails, despite continuous demanding usage.

The Basics of Using Molybdenum in CNC Machining Applications

Molybdenum is a chemical element possessing several unique physical and chemical properties. Notably, it’s known for its high melting point (2623°C) and thermal conductivity. This makes the material uniquely suited to bear high-temperature and pressure environments without experiencing deformation or loss in strength. Its atomic number is 42 and comes under transition metals boasting significant electrical conductivity.

These distinctive characteristics make molybdenum an invaluable resource for general manufacturing applications. Some common uses of molybdenum involve:

- Electrical and electronics applications due to its excellent conductivity

- Construction of aircraft parts and industrial motors owing to its heat resistance capability

- Production of stainless steel and alloy steels as it gives robustness and corrosion resistance, thereby enhancing the longevity of these products

In short, when used within CNC machining, molybdenum improves not only durability but also widens the application possibilities of manufactured products.

Molybdenum in CNC Machining Applications

The use of molybdenum in CNC machining applications brings several benefits that enhance the performance and longevity of the machine parts. This element is endowed with key physical properties such as high melting point, low thermal expansion rates, and good thermal conductivity, which significantly improve precision, durability, and heat resistance in CNC machining operations.

- Improved Precision: Molybdenum offers great stiffness and minimal deformation under loads, enabling it to deliver high accuracy in intricate manufacturing processes.

- Durability: Due to its impressive hardness and corrosion resistance characteristics, components made from Molybdenum demonstrate extended lifespan even under severe working conditions.

- Heat Resistance: The ability of Molybdenum to withstand extreme temperatures makes it a preferred choice for high-speed machining applications where substantial heat is generated.

For instance, in the aerospace industry – where precision-tolerance and high-temperature resistant components are critical – the implementation of Molybdenum contributes substantially towards achieving uncompromised part integrity and operational safety.

Detailed Advantages of Using Molybdenum in CNC Machining Applications

- Molybdenum improves the corrosion resistance and strength of stainless steel, making it suitable for applications in aggressive environments.

- It enhances the machinability of steel, allowing for efficient CNC machining processes and the production of intricate parts.

- Molybdenum’s high melting point and thermal conductivity make it ideal for use in high-temperature applications, such as aerospace and automotive components.

- Its ability to alloy with various metals expands the range of materials that can be used in CNC machining, providing versatility in part design and manufacturing.

Comparing Molybdenum with Other Metals Used in CNC Machining

When compared to commonly-used metals like steel or aluminum, molybdenum exhibits notable benefits for use in Computer Numerical Control (CNC) machining applications. Firstly, its cost-effectiveness is apparent as molybdenum parts demonstrate a long life cycle thanks to their high melting point and impressive durability – attributes that can decrease the need for part replacements, thus lowering operational expenses over time.

- Efficiency: Molybdenum boasts excellent thermal conductivity, heat resistance and minimal thermal expansion properties which enhance the efficiency of CNC machining operations.

- Performance: With unparalleled strength-to-weight ratios, exceptional corrosion resistance and a capacity to function optimally under extreme temperature variations, molybdenum enhances the performance and reliability of machined components.

In conclusion, while traditional metals such as steel or aluminium are widely used in CNC machining, there’s clear evidence pointing towards numerous advantages regarding the usability, efficiency, and performance when incorporating molybdenum into these processes.

Potential Challenges in Using Molybdenum in CNC Machining

The utilization of molybdenum in CNC machining applications presents some distinct challenges for manufacturers. Despite its numerous advantages, molybdenum’s high melting point and strength can lead to difficulties during the cutting process including machine wear and tear, poor surface finish, and increased power consumption. Additionally, due to its oxidizing nature when exposed to air at elevated temperatures, there are potential safety risks involved.

- One recommended solution to mitigate these issues is the use of tailored coatings, specifically designed for high-speed steel or carbide tooling, which can significantly reduce friction, thereby lowering heat generation and prolonging tool life span.

- To combat oxidation problems, operating within a controlled environment is suggested. This could entail conducting machining operations under an inert gas like argon that precludes any risk of fire or explosion.

All in all, with prudent processing techniques and adequate safety measures, the drawbacks related to molybdenum-based CNC machining can be effectively addressed.

Conclusion

In conclusion, the use of molybdenum in CNC machining offers a significant competitive advantage to industries. This versatile metal has intrinsic properties such as high melting point and superior hardness that enhance the performance and durability of machine parts, leading to improved production efficiency and lower maintenance costs. However, integrating this beneficial element into your CNC machining operations requires technical understanding and expertise. Therefore, it is recommended for decision makers and technicians to conduct further research or consult with industry experts for effective implementation strategies.

- molybdenum’s high melting point improves part resistance to heat damage,

- its exceptional hardness enhances component durability,

- the combination of these benefits leads to increased operational efficiency and reduced maintenance expenditure,

- but proper integration necessitates further study or specialist consultation.

Related Posts

- Unraveling the World of CNC Machined Plastic Parts(CNC machined plastic parts Mabel)

Modern innovations have taken traditional manufacturing methods to new heights. One such innovation that stands out is Computer Numerical Control (CNC) machining, a process used extensively in various industries from…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…