Introduction to CNC Machining

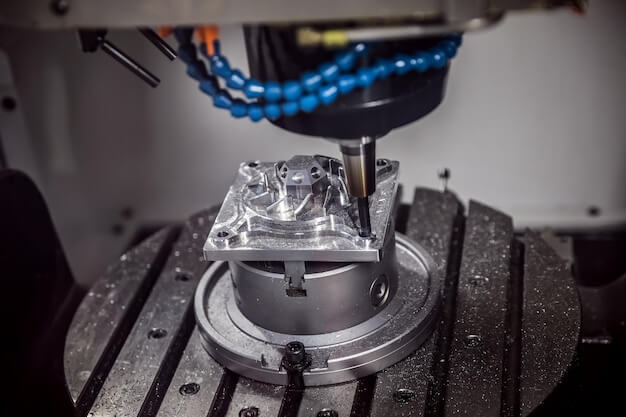

CNC machining stands as a cornerstone in modern manufacturing, offering precision and efficiency in producing parts. At its core, CNC (Computer Numerical Control) machining involves the use of computers to control machine tools, ensuring high accuracy and repeatability. The selection of materials for machining is critical, directly influencing the machining speed and the wear on tools. Different materials, ranging from metals to plastics, possess unique properties that affect their machinability. For instance, harder materials typically result in slower machining speeds and increased tool wear, necessitating careful consideration during the material selection process to optimize production efficiency and tool longevity.

- Machining Speed: Determined by the material’s hardness and machinability, impacting production time.

- Tool Wear: Influenced by the material’s abrasiveness and hardness, affecting tool replacement costs and downtime.

Understanding Material Selection in CNC Machining

In CNC machining, material selection is crucial as it directly influences machining speed and tool wear. Different materials, such as metals and plastics, necessitate distinct machining approaches due to their unique properties. Metals, for example, often require slower machining speeds and may lead to quicker tool wear due to their hardness and abrasiveness. In contrast, plastics can be machined at higher speeds but may require specific tools to prevent melting or deformation. An example of this principle in action is the machining of aluminum versus stainless steel; aluminum allows for faster machining speeds and less tool wear compared to stainless steel, which is tougher and requires more careful handling to avoid damaging the tool. This differentiation in approach underscores the importance of understanding material properties to optimize machining efficiency and tool lifespan.

- Metals: Require slower speeds, more prone to causing tool wear.

- Plastics: Allow for higher speeds, need specific tools to avoid damage.

Impact on Machining Speed

The choice of material significantly influences the speed of the CNC machining process. Materials with different properties require adjustments in machining parameters to optimize cutting speed, tool life, and finish quality. For instance:

- Aluminum: Known for its softness and low density, aluminum allows for higher machining speeds compared to harder materials. This results in shorter machining times for parts made from aluminum.

- Steel: In contrast, steel’s higher hardness and strength necessitate slower machining speeds to prevent excessive tool wear and achieve the desired surface finish. This leads to longer machining times when working with steel.

Therefore, the selection of material directly impacts the efficiency of the CNC machining process, with softer materials generally allowing for faster machining speeds.

Balancing Speed and Tool Wear

When considering the impact of material selection on CNC machining speed and tool wear, it’s essential to balance the need for high-speed machining with the potential for increased tool wear. Certain materials may allow for faster cutting speeds, but they can also accelerate tool wear. Finding the optimal balance between machining speed and tool longevity is crucial for maximizing efficiency and reducing production costs. For more information on precision machining services, visit Precision Machining Service.

Balancing Speed and Tool Wear in CNC Machining

In CNC machining, the selection of materials significantly influences both machining speed and tool wear. Manufacturers must navigate a delicate balance between these two factors to optimize production efficiency and cost-effectiveness. Choosing a material that allows for high-speed machining might lead to increased tool wear, necessitating frequent replacements and potentially elevating costs. Conversely, materials that minimize tool wear might require slower machining speeds, reducing overall productivity. Decisions are often based on:

- The nature of the project, considering the required precision and finish.

- Cost implications of tool replacement versus the value of increased production speed.

- Long-term durability and performance requirements of the machined parts.

For example, machining soft aluminum alloys might allow for high speeds but could lead to quicker tool degradation compared to harder steel alloys, which might be machined at slower speeds but offer extended tool life. Thus, manufacturers must assess the trade-offs to determine the most cost-effective and efficient material and machining parameters for each project.

Case Study: Optimizing CNC Machining Through Material Selection

In a real-world manufacturing project, the selection of aluminum 6061 for a series of aerospace components significantly influenced both machining speed and tool wear. The project’s goal was to optimize production efficiency while maintaining high precision and durability of parts. The choice of aluminum 6061 was pivotal due to its excellent machinability, strength-to-weight ratio, and corrosion resistance, which are critical for aerospace applications.

- Material Selection: Aluminum 6061 was chosen for its balance between machinability and physical properties.

- Machining Speed: The use of aluminum 6061 allowed for higher machining speeds, reducing production time by 20% compared to other alloys.

- Tool Wear: Despite the increased speed, tool wear was minimized, extending the lifespan of cutting tools by 15% due to the material’s lower hardness and abrasiveness.

This case study underscores the importance of material selection in CNC machining processes, demonstrating how the right material can enhance production efficiency and tool longevity without compromising the quality of the final product.

Related Posts

- The Engineer's Guide to Reducing CNC Machining Time: Material and Tool Selection Strategies

Importance of Reducing CNC Machining Time In the expansive world of industrial manufacturing, Computer Numerical Control (CNC) machining holds a dominant place due to its effectiveness in reducing errors, enhancing…

- Tool compensation in CNC machining, our quest for precision in CNC machining

Introduction to CNC Machining and Precision CNC (Computer Numerical Control) machining stands at the forefront of modern manufacturing, utilizing computerized controls to operate complex machinery with remarkable accuracy. This process…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…