Introduction to CNC Machining in the Chemical Industry

CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, offering precision and efficiency by automating the control of machine tools with computer systems. Its significance is particularly pronounced in the chemical industry, where the demand for corrosion-resistant materials is high. This industry requires components that can withstand aggressive chemicals without degrading over time. For example, in the production of pharmaceuticals, CNC machined parts made from corrosion-resistant materials ensure the longevity and reliability of the manufacturing equipment. This necessity stems from the harsh environments these materials encounter, including exposure to acidic or basic substances, which can quickly erode standard materials. Therefore, selecting the right material, such as stainless steel or titanium, is crucial for components in chemical processing equipment, highlighting the tailored approach CNC machining offers to meet these specific industry needs.

Understanding Corrosion in the Chemical Industry

Corrosion in the chemical industry is a critical concern, as it directly impacts the durability and functionality of machinery and components. This degradation process, primarily caused by chemical reactions between the material and its environment, can lead to significant economic losses and safety hazards. The types of corrosion encountered include:

- Uniform Attack: This is the most common form of corrosion, characterized by a uniform removal of material surface. It’s predictable and often manageable through material choice and protective coatings.

- Pitting Corrosion: Results in small, localized holes on the material surface, often hard to detect and can lead to sudden failures, especially in pipelines and tanks.

- Stress Corrosion Cracking (SCC): Caused by the combined effects of tensile stress and a corrosive environment, leading to cracks. SCC is particularly dangerous because it can occur without significant loss of the material’s overall thickness.

- Galvanic Corrosion: Occurs when two different metals are in contact in a corrosive environment, leading to accelerated attack on the more anodic material.

For example, in heat exchangers, where different metals may come into contact, selecting materials that are less prone to galvanic corrosion is crucial to prevent premature failure.

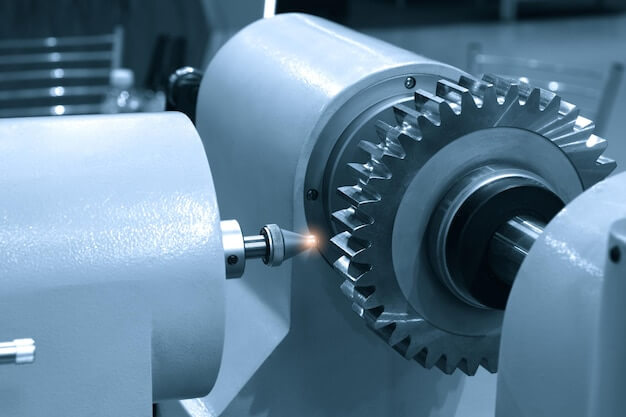

The Role of CNC Machining in Combating Corrosion

CNC machining plays a pivotal role in the chemical industry by producing parts that are resistant to corrosion. This process ensures the high precision required for manufacturing components that come into frequent contact with corrosive substances. Precision is crucial because even minor imperfections can lead to leaks or contamination, compromising the safety and efficiency of chemical processing systems. CNC machining achieves this through:

- Exact material removal, allowing for the creation of complex shapes that fit perfectly together, minimizing exposure to corrosive elements.

- The use of corrosion-resistant materials like stainless steel, titanium, and certain plastics, which are less susceptible to damage from chemicals.

- Advanced programming capabilities that enable the production of parts with tight tolerances, ensuring that components seal properly and function reliably in harsh chemical environments.

For example, in the production of a chemical reactor, CNC machining can be used to create a seamless interior surface that reduces the risk of corrosion and extends the lifespan of the reactor. This illustrates the importance of CNC machining in manufacturing durable, high-quality parts for the chemical industry.

Material Choices for Corrosion Resistance

When considering material choices for corrosion resistance in CNC machining for the chemical industry, it is crucial to evaluate factors such as chemical compatibility, temperature resistance, and durability. Materials like stainless steel, titanium, and certain plastics offer excellent corrosion resistance and are suitable for chemical industry applications.

Success Story of Material Application in the Chemical Industry

In the chemical industry, the strategic selection of corrosion-resistant materials for CNC machined parts has led to significant advancements in operational efficiency and equipment longevity. A notable example involves a company specializing in the production of industrial chemicals, which faced challenges with frequent equipment failures due to corrosion. By transitioning to CNC machined parts made from a high-grade, corrosion-resistant alloy, the company achieved:

- Extended lifespan of machinery components, reducing downtime and maintenance costs.

- Improved safety and reliability of chemical processing equipment.

- Enhanced resistance to harsh chemicals, leading to consistent production quality.

This case underscores the importance of material selection in the chemical industry, demonstrating how corrosion-resistant materials can lead to operational success.

Challenges in Selecting the Right Material for Corrosion Resistance

Selecting the appropriate materials for corrosion resistance in the chemical industry presents several challenges. Key factors to consider include:

- Cost: High-performance materials that offer superior corrosion resistance often come at a higher price. Balancing cost with the need for durability is crucial.

- Availability: Some materials may be difficult to source or have long lead times, impacting project timelines.

- Compatibility: The selected material must be compatible with existing systems and the specific chemicals it will be exposed to. Incompatibility can lead to system failure.

For example, choosing a material for a piping system that will carry highly corrosive chemicals requires a thorough understanding of the chemical properties and how they interact with different materials. Stainless steel might be a common choice for its corrosion resistance, but in environments with high chloride levels, duplex stainless steel, with its enhanced resistance to chloride stress corrosion cracking, might be necessary despite its higher cost.

Related Posts

- Using CNC Machining to Fabricate Lightweight Metal and Remove Chrome From Metal( cnc machining services china Dana)

CNC (Computer Numerically Controlled) machining is an essential process in the manufacturing domain. With its precision, adaptability, and extensive applications, many industries rely on it for fabricating highly complex parts…

- Efficient CNC Machining of Lightweight Metal and Chrome Removal( cnc machining services china Atwood)

Computer Numerical Control (CNC) machining is a modern manufacturing process used in various industries, frequently dealing with lightweight metals or needing to remove chrome from metal surfaces. This article will…

- Material Flexibility in CNC Machining: Engineering Soft Materials for Complex Parts

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and repeatability that are unmatched by manual processes. At its core, CNC (Computer Numerical Control)…