Introduction to Bead Blasting and Copper Plating in CNC Machining

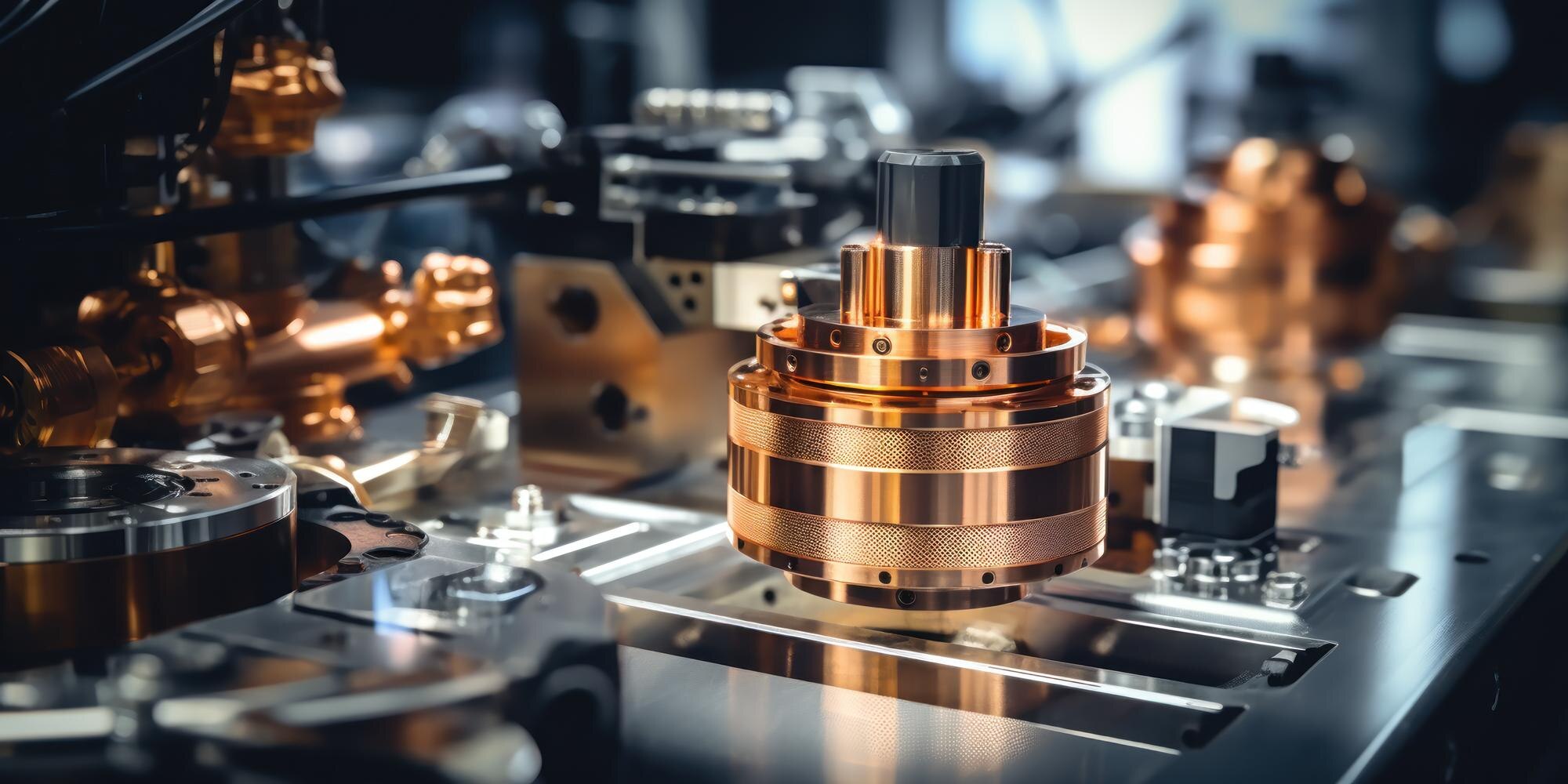

In the realm of modern manufacturing, CNC machining stands as a paragon of precision engineering, transforming raw materials into finished products with unparalleled accuracy. Within this domain, surface finishing techniques such as bead blasting and copper plating play pivotal roles, not only in enhancing the aesthetic appeal of the parts but also in significantly improving their functional properties. Bead blasting, a process that propels abrasive bead media against the surface of a part, meticulously alters the surface texture to achieve desired finishes. Copper plating, an electrochemical process, coats the machined parts with a thin layer of copper, imbuing them with superior electrical conductivity and resistance to corrosion, making it indispensable in electrical and electronic applications.Now, you can submit processing requirements such as copper plating through the Internet and obtain cnc machining parts quotation.

Challenges in Bead Blasting: Precision and Uniformity

Achieving a high degree of precision and uniformity in bead blasting is fraught with challenges. The process demands meticulous control over various parameters, including the size and type of abrasive media, blasting pressure, and the angle of media impact. Any discrepancies in these factors can lead to non-uniform surface textures, which, in critical applications like aerospace and medical devices, could compromise the functionality of the components.

Case Study: Precision in Aerospace Components

Consider the case of an aerospace manufacturer tasked with producing turbine blades. The uniformity of the surface finish on these blades is paramount, as it directly influences the aerodynamics and, consequently, the overall performance of the aircraft. The manufacturer employed a state-of-the-art bead blasting machine with programmable controls to regulate the pressure and flow of the bead media, ensuring a consistent and reproducible surface finish across all blades, thereby meeting the stringent aerospace industry standards.

Copper Plating Complexity: Adhesion and Thickness Control

Copper plating, a critical process in CNC machining, involves electrochemically depositing a layer of copper onto machined parts. This technique enhances electrical conductivity and provides resistance against corrosion. However, mastering copper plating requires navigating two primary complexities: achieving optimal adhesion and controlling the layer’s thickness.

Adhesion is paramount in copper plating; poor adhesion can lead to layer peeling, compromising the part’s integrity and functionality. Factors influencing adhesion include the cleanliness of the substrate, the plating solution’s chemical composition, and the pre-treatment processes. Thorough cleaning and surface preparation, such as acid etching or applying a zincate layer for non-ferrous substrates, are critical steps to ensure strong adhesion.

Thickness control is equally vital. The copper layer must be thick enough to provide the desired conductivity and durability without compromising the part’s dimensions or fitting. Precision in controlling the electroplating parameters, such as current density, temperature, and plating time, is essential to achieving the desired thickness.

Enhanced Data Table: Detailed Copper Plating Parameters

| Parameter | Optimal Range | Impact | Industry Application |

|---|---|---|---|

| Current Density (A/dm²) | 2-4 | Ensures uniform deposition | General electronics |

| Bath Temperature (°C) | 20-25 | Stabilizes reaction rates | Aerospace components |

| pH Level | 1.0-1.5 | Balances copper ion availability | Medical devices |

| Plating Time (min) | 15-30 | Controls layer thickness | Automotive parts |

| Agitation Speed (rpm) | 100-200 | Prevents deposit irregularities | Consumer electronics |

| Anode-Cathode Distance (cm) | 10-15 | Optimizes current distribution | Industrial machinery |

| Bath Composition | Varied | Tailored for substrate compatibility | Telecommunications |

| Substrate Pre-treatment | Custom | Ensures adhesion | Renewable energy components |

| Additives | Specific | Enhances properties like brightness | Decorative items |

| Post-treatment | Required | Improves durability | Marine applications |

Innovative Solutions from China: Overcoming Bead Blasting Limitations

China’s rapid advancement in manufacturing technologies has led to significant innovations in bead blasting, addressing common limitations such as uneven surface finishes and damage to delicate parts. One notable innovation involves the development of a robotic bead blasting system equipped with precision sensors and AI algorithms. This system can adapt the blasting intensity and angle in real-time, based on the part’s geometry and desired finish, ensuring uniform surface quality across complex shapes.

Case Study: Robotic Bead Blasting in Automotive Parts

An automotive parts manufacturer in China implemented this robotic bead blasting technology to finish aluminum wheel rims. The traditional manual process had resulted in inconsistencies and occasional damage to the delicate edges of the rims. The robotic system, with its precise control, not only standardized the finish across all rims but also reduced processing time by 30%, showcasing the potential of automation in enhancing both efficiency and quality in bead blasting.

Advancements in Copper Plating: Enhanced Durability and Conductivity

Recent advancements in copper plating technology in China focus on enhancing the durability and conductivity of the plated layers, crucial for electronic components. One breakthrough is the introduction of a nano-copper plating solution, which results in a denser, more uniform copper layer with improved adhesion properties. This nano-plating technique significantly increases the durability and conductivity of the plated parts, making it highly suitable for high-performance electronic applications.

Data Table: Comparison of Traditional vs. Nano Copper Plating

| Feature | Traditional Copper Plating | Nano Copper Plating |

|---|---|---|

| Layer Uniformity | Good | Excellent |

| Adhesion Strength | Moderate | High |

| Conductivity | High | Very High |

| Durability | Moderate | High |

| Application Suitability | General | High-performance Electronics |

Integrating Bead Blasting with Copper Plating: A Synergistic Approach

The integration of bead blasting and copper plating within the CNC machining workflow heralds a new era of manufacturing precision and efficiency. This synergistic approach leverages the abrasive fine-tuning capability of bead blasting to prepare the substrate for optimal copper adhesion and uniform layer distribution. Bead blasting, by carefully modulating the surface texture, enhances the mechanical interlocking between the copper layer and the substrate, significantly improving the adhesion strength and longevity of the plating.

Moreover, the controlled roughness achieved through bead blasting facilitates a more homogeneous copper deposition during the plating process. This uniformity is crucial in applications where electrical conductivity and resistance to corrosion are paramount. By ensuring a consistent copper layer thickness across the part, manufacturers can achieve superior performance characteristics, including enhanced electrical properties and increased resistance to environmental degradation.

This integrated approach not only optimizes the individual benefits of bead blasting and copper plating but also introduces new possibilities for manufacturing complex parts with stringent requirements for surface finish, conductivity, and durability. Industries such as aerospace, automotive, and electronics, where the integrity and performance of components are critical, stand to benefit immensely from this advanced manufacturing technique.

In the realm of telecommunications, for example, the demand for high-performance connectors with exceptional conductivity and environmental resistance has driven manufacturers to adopt this integrated approach. By first bead blasting the connector substrates to achieve a perfectly calibrated surface texture and then applying a uniform copper plating, these components exhibit unmatched performance in signal transmission and durability, meeting the rigorous standards of the telecommunications industry.

Future Directions in CNC Machining: Beyond Bead Blasting and Copper Plating

Looking forward, the future of CNC machining is poised to transcend current technologies like bead blasting and copper plating. Innovations in surface finishing techniques are expected to leverage advanced materials, precision automation, and environmentally friendly processes. Anticipated developments include the use of laser texturing for ultra-precise surface finishes and the adoption of green plating technologies that minimize environmental impact while enhancing performance.

Data Table: Projected Advancements in Surface Finishing Techniques

| Technology | Key Feature | Expected Benefit |

|---|---|---|

| Laser Texturing | Sub-micron precision | Enhanced surface functionality |

| Green Plating Solutions | Non-toxic chemicals | Reduced environmental impact |

| Automated Surface Analysis | Real-time feedback | Optimized finishing processes |

| Hybrid Finishing Systems | Combination of techniques | Customized surface properties |

In conclusion, the integration of bead blasting and copper plating within the CNC machining process, especially with the innovations coming out of China, represents a significant leap forward in manufacturing quality and efficiency. As we look to the future, the ongoing evolution of surface finishing technologies promises to further elevate the capabilities of CNC machining, driving advancements in a wide range of industries.

Related Posts

- High-Precision CNC Machining for Advanced Semiconductor Manufacturing

Introduction: CNC Machining and its Role in Advanced Semiconductor Manufacturing CNC machining, or Computer Numerical Control machining, refers to the process of subtracting material with high-speed precision machinery instructed by…

- Understanding and Exploring Bead Blasting in CNC Machining(copper plating Murray)

Bead blasting is an integral process in the realm of Computer Numerical Control (CNC) machining, often used for finishing or cleaning metal components. In simple terms, bead blasting involves leveraging…

- Duplex Stainless Steel vs. Super Duplex in CNC Machining: Features and Applications?

Introduction to CNC Machining and Duplex Stainless Steels In the domain of manufacturing, Computer Numerical Control (CNC) machining plays a pivotal role due to its precision, efficiency, and versatility. Essentially,…