Molybdenum Alloys and Precision CNC Machining: An Introduction

Molybdenum alloys, known for their high melting point and thermal conductivity, are integral to the world of precision Computer Numerical Control (CNC) machining. CNC machining is a subtractive production method that uses computer-controlled machines to remove material from workpieces and fashion them into desired parts. Designed with superior strength and resistance to corrosion and wear, molybdenum alloys play a pivotal role in this process, especially within strenuous environments where durability and heat stability are paramount.

- CNC Machining: A technique used for transforming raw material into precise components. It offers unparalleled accuracy through automated cutting process governed by pre-programmed software.

- Molybdenum Alloys: These alloys exhibit excellent hardenability, making them suitable for applications requiring both strength and hardness. They have low coefficient of thermal expansion, which enables them to retain their structure even under high temperatures.

A tangible application of this synergy lies in the aerospace industry where high-performance parts must withstand extreme conditions without compromising functionality or safety. The precision offered by CNC machining combined with the robust characteristics of molybdenum alloys yield durable, reliable components able to endure the rigors of spaceflight.

What is Molybdenum?

Molybdenum is a refractory metallic element found in the periodic table under group 6, and period 5, with symbol ‘Mo’ and atomic number 42. It exhibits characteristics such as exceptional strength at elevated temperatures, impressive electrical conductivity, and robust resistance to corrosion and wear. Furthermore, it has one of the highest melting points amongst all elements, making it especially advantageous for high-stress applications requiring temperature resilience.

An integral reason behind using molybdenum frequently within alloys is its inherent ability to significantly enhance the hardness and durability of metals while maintaining ductility and impact strength. This unique attribute helps improve the performance and lifespan of components exposed to severe operational conditions. For example, in an alloy with steel, molybdenum can increase tensile strength, corrosion resistance and can stand up to extreme temperatures without significant expansion or softening – properties particularly useful in industries ranging from aerospace to automotive manufacturing.

What are Molybdenum Alloys?

Molybdenum alloys are metallurgical products made by combining this transition metal with other elements to improve properties for specific applications. These alloys, differing based on composition, exhibit a unique blend of strength, toughness, and resistance – making them highly vital in various industries.

- Pure Molybdenum & TZM: Pure molybdenum, while not an alloy itself, serves as the base for all molybdenum alloys. It offers high melting points and excellent conductivity. TZM (Titanium-Zirconium-Molybdenum) is its widely-used variant that enhances creep resistance.

- Molybdenum-Rhenium: This binary alloy, typically composed of 41% or 47.5% rhenium, is used often in electronics owing to exceptional ductility at room temperature.

- MHC (Molybdenum-Hafnium-Carbide): With hafnium and carbide additions, it finds relevance in industrial heating applications due to superior strength and stability at high temperatures.

Each of these alloys have distinct characteristics fulfilling different industrial demands. However, all share a common trait: elevated performance under extreme conditions compared to many standard metals.

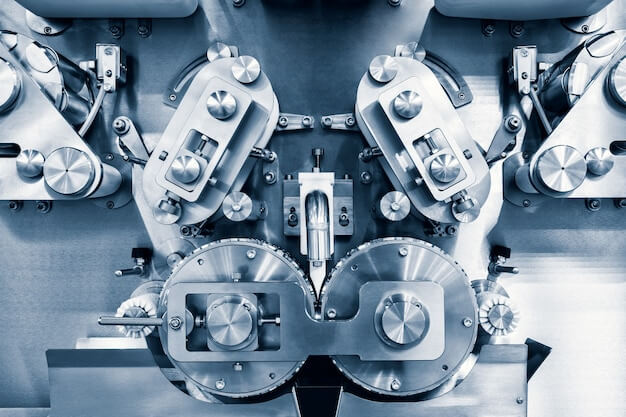

Understanding Precision CNC Machining

The addition of molybdenum (2 to 4 wt. %) improves the corrosion resistance and strengthens the 316L stainless steel grade, reducing the risk of pitting corrosion and the release of nickel and chromium ions. This enhancement makes molybdenum alloys highly advantageous for precision CNC machining applications, particularly in industries with stringent quality requirements such as aerospace and medical device manufacturing.

Why Use Molybdenum Alloys in Precision CNC Machining?

Molybdenum alloys hold significant compatibility with precision Computer Numerical Control (CNC) machining due to their unique mechanical properties. For instance, these alloys possess excellent strength and stability at high temperatures that make them a preferred choice for industries like aerospace where other metals often warp or degrade under intense heat. They also offer better electrical and thermal conductivity which are critical factors in efficient CNC operations.

- The high melting point of molybdenum prevents deformation during the machining process thus ensuring precise results.

- They exhibit exceptional resistance to wear and tear resulting in an extended lifespan of machine parts made using molybdenum alloys.

A notable example illustrating the advantage of this alloy is seen in the spacecraft and satellite production industry where precision and reliability are paramount. Here, components machined from molybdenum alloys were exposed to extreme environmental conditions but showed consistent performance without any signs of degradation.

Application of Molybdenum Alloys in Precision CNC Machining

Molybdenum alloys are consistently sought after in various industrial sectors due to their unique physical properties, something that is particularly beneficial in the field of precision CNC machining. Notably common applications for these alloys can be found within areas including automotive, aerospace, and electrical industries. Each of these industries requires a degree of precision and reliability that molybdenum alloys can help provide.

An example of this application is prevalent in aerospace technology where high strength and heat resistant components are critical. Here, molybdenum alloys offer superior thermal conductivity and low expansion properties, which make them ideal for creating parts that can withstand extreme conditions. In this process, precision CNC machining techniques are used to manufacture intricate parts such as turbine blades and jet engine nozzles with exceptional accuracy and repeatability, thus underscoring the inherent value of these versatile alloys.

Concluding Thoughts on Molybdenum Alloys in Precision CNC Machining

In summary, the use of molybdenum alloys in precision CNC machining offers a plethora of advantages and applications. They contribute to increased strength, elasticity, and resistance to wear, making them suitable for high-stress environments like aerospace or machinery production.

- Their commendable electrical and thermal conductivity allows them to function efficiently even under extreme temperatures.

- As a biocompatible material, they also find essential utilization in medical devices, enhancing lifespan and reliability.

However, despite these benefits, there are some considerations to bear in mind when selecting molybdenum alloys. For instance, their susceptibility to oxidation at elevated temperatures might necessitate protective measures. It’s also vital to consider any cost implications as molybdenum can be more expensive compared to other metals. Making an informed choice requires balanced consideration between its outstanding properties and potential challenges.

Related Posts

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…

- Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their…