About Acetal

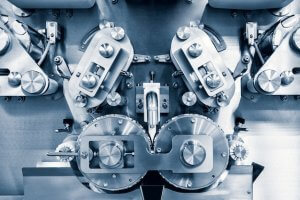

Acetal is a type of thermoplastic material that is also known as polyoxymethylene (POM). It is a highly versatile material that is commonly used in CNC machining due to its excellent mechanical properties, such as high stiffness, low friction, and good dimensional stability.

Acetal is also resistant to abrasion, impact, and chemicals, making it an ideal choice for applications that require high performance and durability. In addition, acetal is easy to machine, making it a popular choice for CNC machining. It can be machined to tight tolerances, and it has good surface finish and excellent dimensional stability.

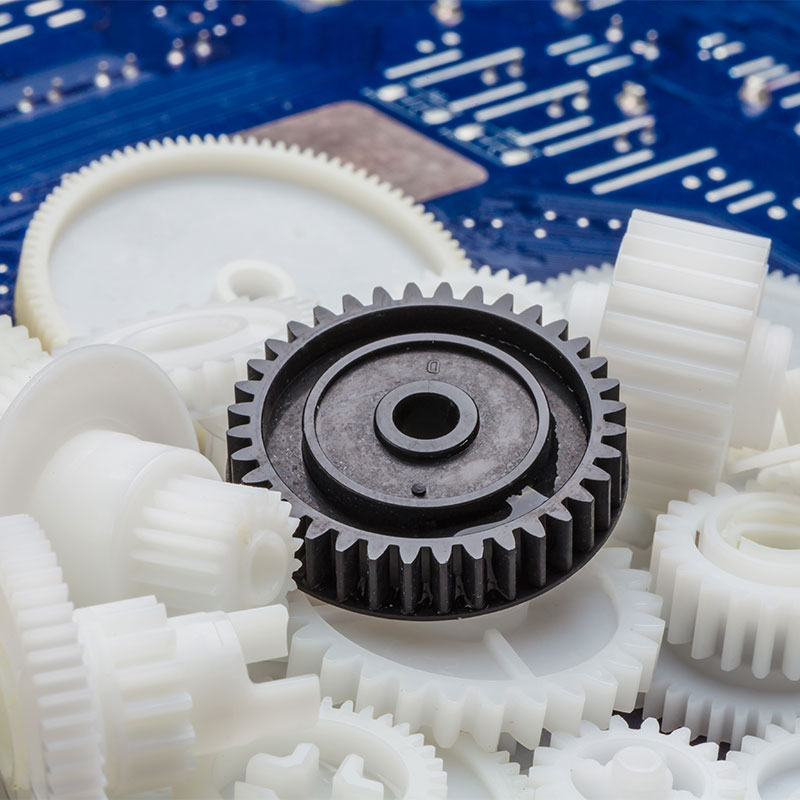

Overall, acetal is a reliable and versatile material that is widely used in CNC machining for various applications, including gears, bearings, valves, and electrical components. Its unique properties make it a popular choice for many industries, including automotive, aerospace, medical, and consumer goods.