Polyester is a category of synthetic polymers primarily derived from petroleum-based substances. It is widely used in various industries due to its excellent mechanical properties, chemical resistance, and durability. Polyester materials exist in both thermoplastic and thermosetting forms, making them highly versatile for different applications, including textiles, packaging, electronics, automotive parts, and high-performance composites.

Polyester materials are known for their high tensile strength, good dimensional stability, and resistance to moisture, chemicals, and UV radiation. These properties make polyester an ideal choice for industrial and consumer applications. One of the most commonly recognized polyesters is polyethylene terephthalate (PET), which is used in beverage bottles, food containers, and textile fibers. Another prominent type is polybutylene terephthalate (PBT), which is widely used in electrical components, automotive parts, and mechanical engineering applications.

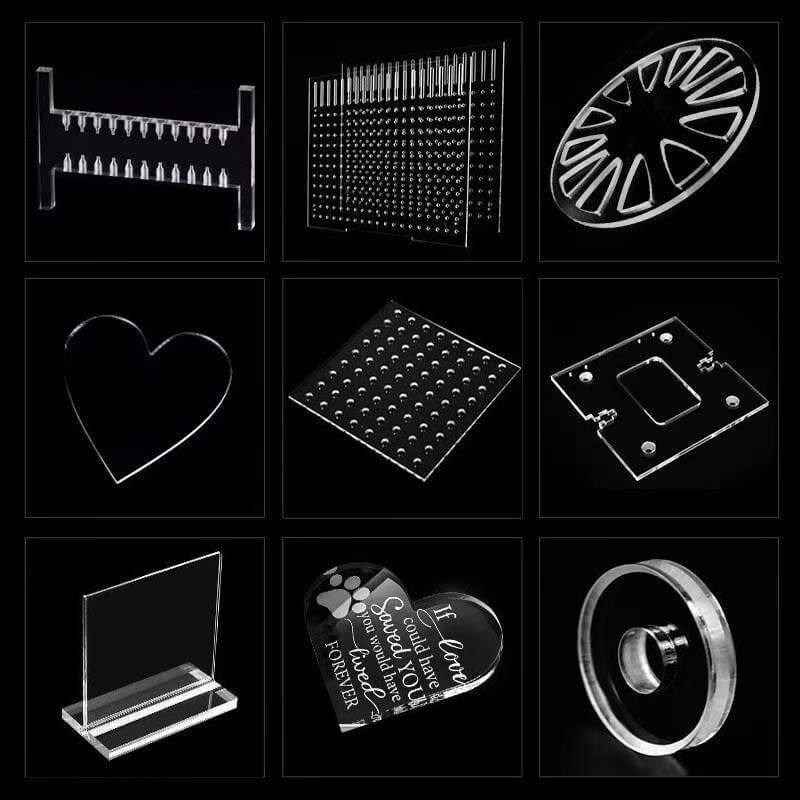

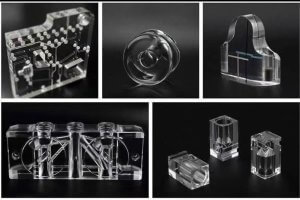

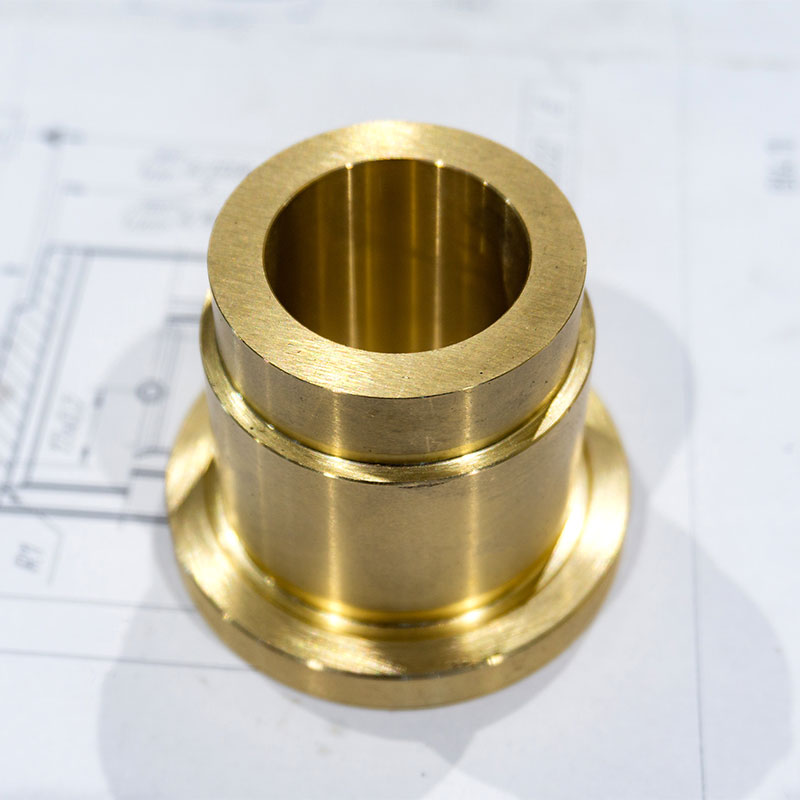

In addition to their standalone properties, polyester materials can be reinforced with additives such as glass fiber or carbon fiber to enhance their strength, rigidity, and heat resistance. These enhancements make polyester an excellent choice for Custom Machining, allowing manufacturers to tailor materials to specific performance requirements. This makes them suitable for CNC machined parts, where precision, durability, and stability are critical. By leveraging these reinforced polyester materials, industries can produce high-quality components that meet stringent mechanical and environmental demands.

And polyester can be used in 3D printing, primarily in the form of PETG (Polyethylene Terephthalate Glycol-Modified), which is popular for FDM/FFF printing due to its strength, flexibility, and chemical resistance. Other polyester-based materials, such as resin-based polyesters, are used in SLA/DLP printing for high-detail applications. While pure polyester is less common in 3D printing due to high processing temperatures, modified versions like PETG offer excellent printability, durability, and impact resistance, making them ideal for industrial and consumer applications. Proper moisture control and temperature settings are essential for optimal results.

Polyester is also valued for its recyclability, especially in the case of PET, which is extensively used in sustainable packaging solutions. The ability to recycle and reuse polyester-based materials contributes to reducing environmental impact while maintaining high-quality performance standards.

From a manufacturing perspective, polyester can be processed through various methods, including injection molding, extrusion, CNC machining, and thermoforming. The choice of processing method depends on the desired product characteristics and performance requirements. The adaptability of polyester materials ensures their ongoing demand in industries such as aerospace, automotive, consumer goods, and construction.