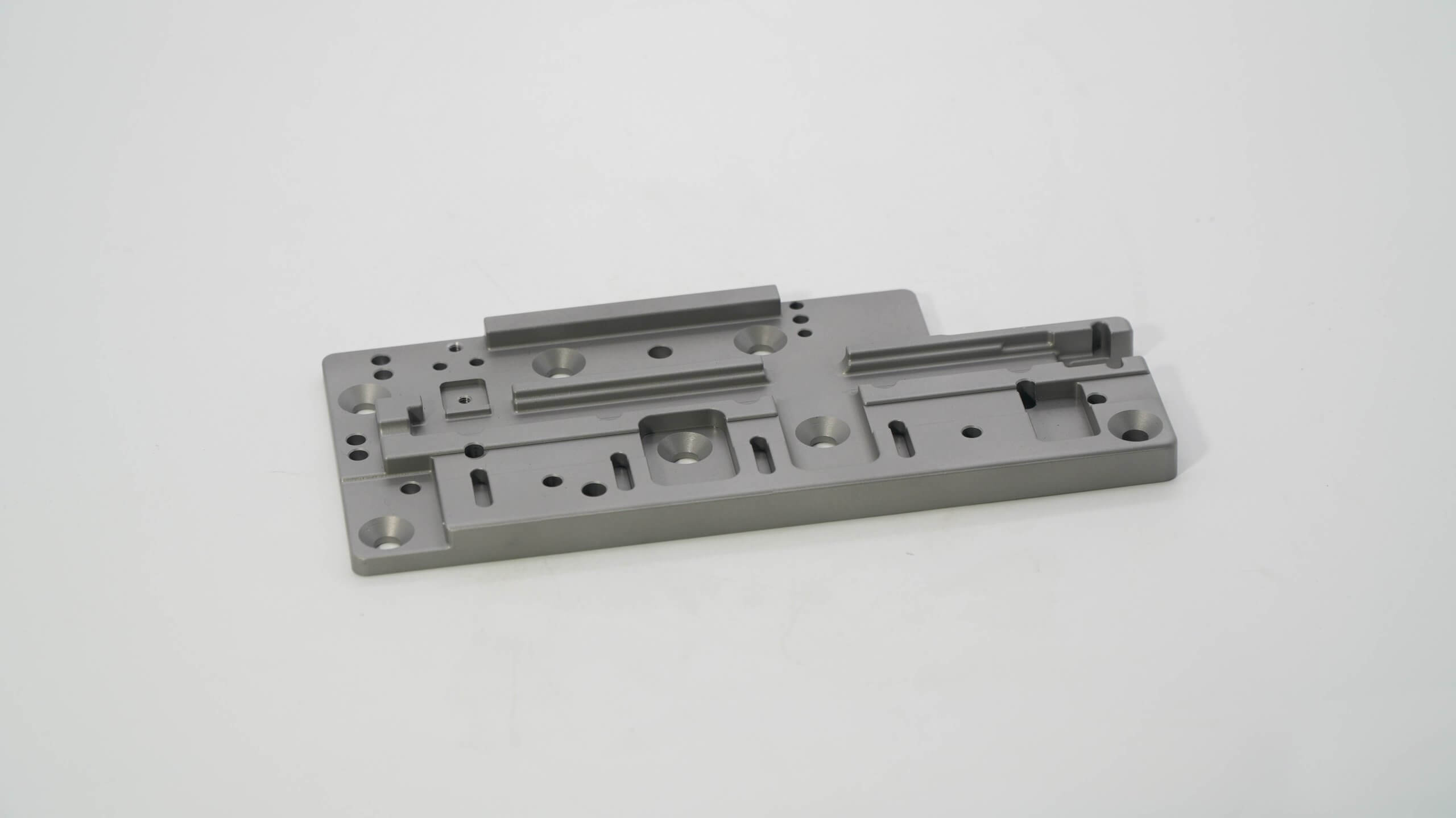

Silicon Carbide Reinforced Aluminum Matrix Composites (SiC/Al) are advanced materials that combine the lightweight and ductility of aluminum with the exceptional strength, hardness, and thermal properties of silicon carbide. These composites are designed to leverage the benefits of both materials, creating a composite that is lightweight yet incredibly strong and resistant to wear, making it ideal for demanding applications in aerospace, automotive, and electronics industries.

The inclusion of silicon carbide particles within the aluminum matrix significantly enhances the composite’s mechanical properties. SiC particles act as reinforcements, increasing the tensile strength, hardness, and modulus of elasticity of the aluminum matrix. This reinforcement not only improves the load-bearing capacity of the material but also enhances its thermal conductivity, making it suitable for high-performance thermal management applications.

Moreover, SiC/Al composites are known for their excellent wear resistance, which is crucial in applications involving sliding or abrasive environments. The combination of lightweight aluminum and hard SiC particles results in a material that can endure high stress and friction without significant wear, extending the lifespan of components made from this composite.

These composites are also favored in industries where weight reduction is critical without compromising strength. The SiC/Al composites’ ability to maintain structural integrity under high temperatures and their superior stiffness-to-weight ratio make them ideal for components in aircraft, high-performance vehicles, and precision instruments.