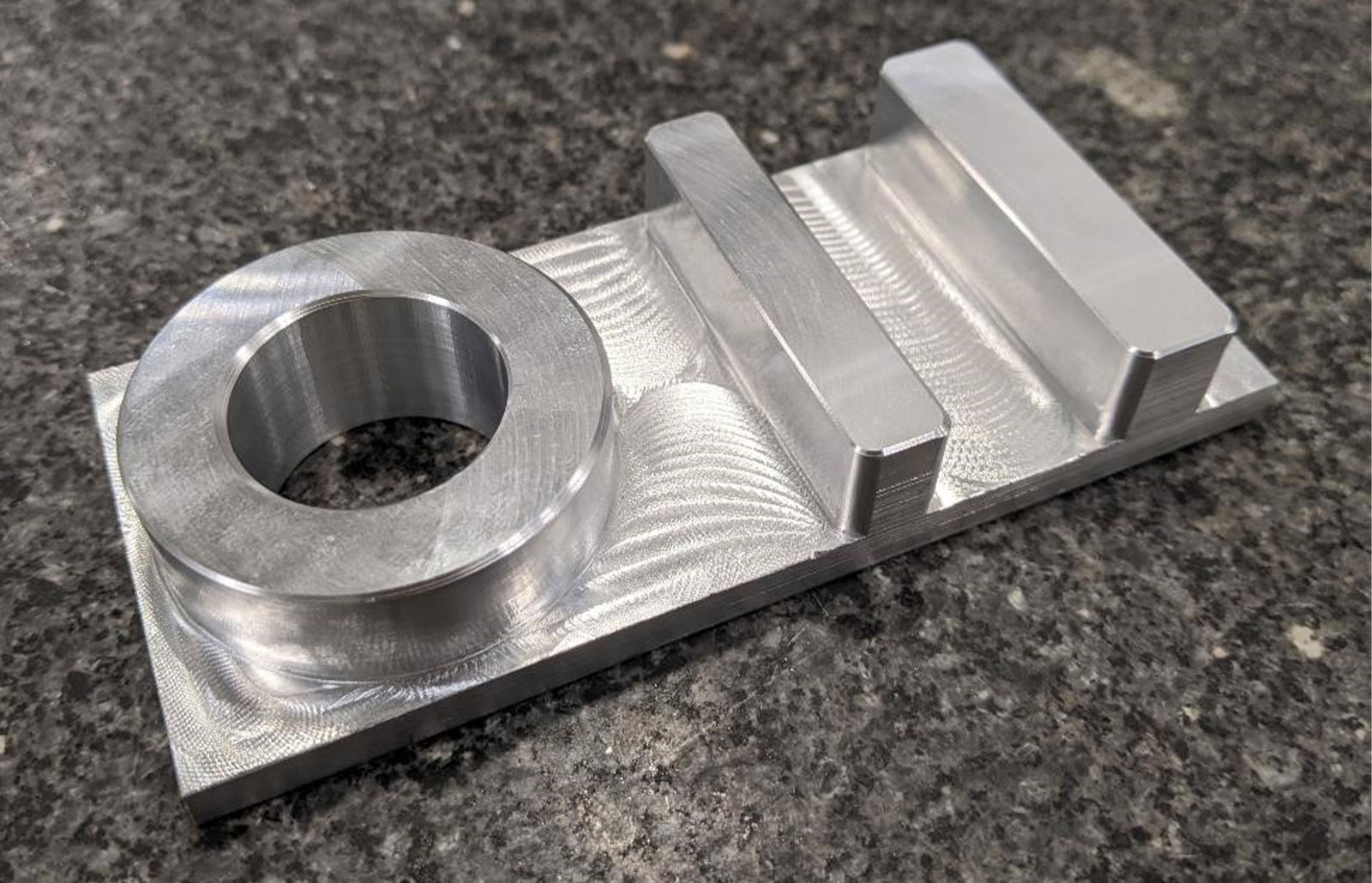

Are you tired of poor surface finish in your CNC machining? Chatter might be the culprit. Chatter is a common problem that can cause poor surface finish, reduced tool life, and even machine damage. But don’t worry, in this article, we’ll show you tips and tricks for minimizing chatter and achieving a better surface finish.

But firstly, what is chatter?

What is Chatter in CNC Machining?

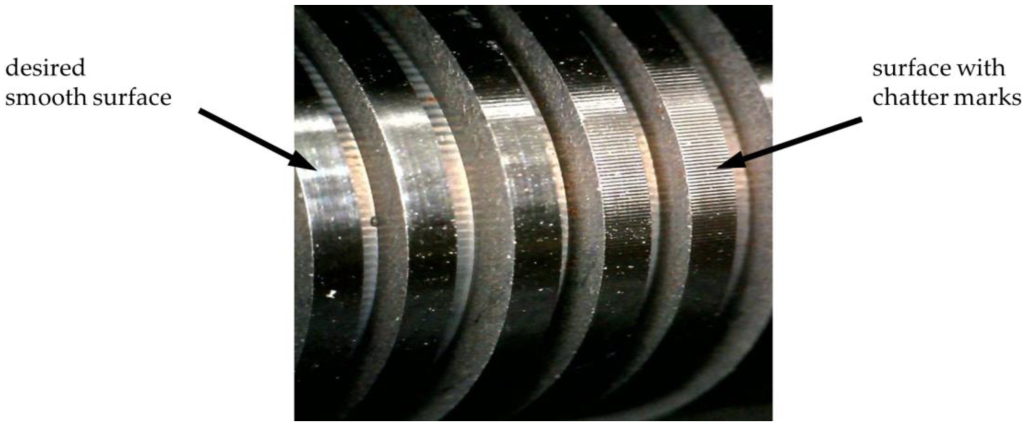

Chatter is an undesired vibration that occurs during CNC machining. It is caused by the interaction between the cutting tool and the workpiece, which generates a self-excited vibration. The vibration can cause the cutting tool to bounce or skip, leading to a poor surface finish, reduced tool life, and even damage to the machine.

Chatter can occur in various forms, including regenerative chatter, forced chatter, and parametric chatter. Regenerative chatter is the most common form and occurs when the vibration frequency matches the natural frequency of the machine-tool-workpiece system. Forced chatter is caused by external factors such as uneven cutting forces or machine tool vibration. Parametric chatter is caused by variations in cutting conditions, such as changes in cutting speed, feed rate, or depth of cut.

Chatter is a significant problem in CNC machining because it can lead to poor surface finish and reduced accuracy of the machined part. If left unaddressed, chatter can also cause excessive tool wear, damage to the machine spindle, and even catastrophic failure of the machine tool. Therefore, it is crucial to understand the causes and types of chatter and take action to minimize it.

Different Types of Chatter

Chatter is a complex phenomenon that can occur in various forms, each with its distinct characteristics. Understanding the different types of chatter can help identify the root cause of the problem and implement the appropriate measures to minimize it.

Regenerative Chatter

Regenerative chatter is the most common type of chatter in CNC machining. It occurs when the vibration frequency matches the natural frequency of the machine-tool-workpiece system. This resonance can cause the cutting tool to bounce, leading to a poor surface finish and reduced tool life. Regenerative chatter is often characterized by a distinctive squealing or screeching noise.

Forced Chatter

Forced chatter is caused by external factors such as uneven cutting forces or machine tool vibration. It can occur at any cutting speed and is not dependent on the natural frequency of the machine-tool-workpiece system. Forced chatter can lead to a poor surface finish and reduced accuracy of the machined part.

Parametric Chatter

Parametric chatter is caused by variations in cutting conditions, such as changes in cutting speed, feed rate, or depth of cut. It occurs when the cutting conditions cause the system’s natural frequency to change, leading to a self-excited vibration. Parametric chatter can cause erratic or inconsistent tool wear and reduced surface finish quality.

By understanding the different types of chatter, you can identify the root cause of the problem and implement measures to minimize it. In the following sections, we’ll explore various tools and techniques for minimizing chatter in CNC machining.

Tools and Techniques for Minimizing Chatter

Tool Selection

Choosing the right cutting tool is critical for minimizing chatter. Different tools have varying levels of rigidity, damping properties, and vibration resistance, which can impact the occurrence of chatter. Some common types of cutting tools include carbide, high-speed steel, and ceramic. Each type of tool has its advantages and disadvantages when it comes to chatter.

For example, carbide tools are rigid and have excellent vibration resistance, making them a good choice for high-speed machining and heavy cuts. However, they can be brittle and prone to breakage if exposed to excessive vibration. High-speed steel tools are more flexible than carbide tools and can dampen vibration, making them a good choice for light cuts and difficult-to-machine materials. Ceramic tools have high wear resistance and can perform well in high-temperature applications but can be brittle and prone to chipping.

By selecting the appropriate cutting tool for the job, you can reduce the risk of chatter and improve surface finish. It’s essential to consider factors such as the material being machined, the cutting conditions, and the desired surface finish when choosing a tool.

Tool Holding

Proper tool holding is essential for minimizing chatter in CNC machining. The cutting tool must be held securely in place to prevent vibration and ensure accurate cutting. Improper tool holding can cause the cutting tool to deflect or vibrate, leading to poor surface finish and reduced tool life.

To ensure proper tool holding, it’s important to follow best practices, such as:

- Using a high-quality tool holder

- Using the correct size and type of collet or chuck

- Cleaning and inspecting the tool holder regularly

- Tightening the tool holder to the recommended torque

The type of tool holder used can also impact chatter. Some common types of tool holders include:

- Collet chucks

- Hydraulic chucks

- Shrink-fit holders

- End mill holders

Each type of tool holder has its advantages and disadvantages when it comes to chatter. For example, collet chucks are widely used and can be inexpensive, but they may not provide sufficient damping and can cause the cutting tool to vibrate. Shrink-fit holders are rigid and provide excellent vibration resistance but can be costly and require specialized equipment.

Cutting Parameters

Cutting parameters such as cutting speed, feed rate, and depth of cut can have a significant impact on chatter. High cutting speeds or feed rates can cause the cutting tool to vibrate or deflect, leading to chatter and a poor surface finish. On the other hand, low cutting speeds or feed rates can cause the tool to rub rather than cut, leading to excessive heat and tool wear.

To minimize chatter and achieve a better surface finish, it’s important to use the optimal cutting parameters for the job. Some general guidelines for selecting cutting parameters to minimize chatter include:

- Use a lower cutting speed and feed rate for harder materials or deeper cuts

- Use a higher cutting speed and feed rate for softer materials or shallower cuts

- Reduce the depth of cut to minimize tool deflection and vibration

- Use a smaller diameter tool for better rigidity and reduced vibration

It’s important to note that the optimal cutting parameters may vary depending on the material being machined, the type of tool being used, and the desired surface finish. Therefore, it’s essential to monitor the cutting parameters and adjust them as necessary to achieve the best results.

Machine and Tool Set-up

Proper machine set-up is crucial, too. The machine should be leveled and secured to the floor to prevent any unwanted movement during cutting. The machine should also be regularly inspected and maintained to ensure that all components are in good condition and functioning properly.

Tool set-up is equally important for minimizing chatter. The cutting tool should be properly installed and tightened to prevent any movement or vibration. The tool should also be checked regularly for wear and replaced as necessary.

You should also ensure that the tool is properly balanced to prevent any vibration during cutting. Unbalanced tools can cause excessive vibration and chatter, leading to a poor surface finish and reduced tool life.

Damping Techniques

Damping techniques are used to reduce vibration and prevent chatter in CNC machining. There are several different types of damping techniques, including:

- Passive damping: Passive damping involves the use of materials with high damping properties, such as rubber or elastomers, to absorb vibration and reduce chatter.

- Active damping: Active damping involves the use of sensors and actuators to monitor and control the vibration of the cutting tool in real-time, effectively minimizing chatter.

- Hybrid damping: Hybrid damping combines passive and active damping techniques to provide an optimal level of damping for specific cutting conditions.

Choosing the appropriate damping technique for your application can depend on various factors, such as the material being machined, the cutting conditions, and the desired surface finish. Passive damping techniques are often more affordable and can be effective in reducing vibration and chatter in many applications. Active damping techniques can be more expensive, but they provide real-time monitoring and control, resulting in higher machining performance and a better surface finish.

Hybrid damping techniques can provide the best of both worlds, with the optimal level of damping for specific cutting conditions. It’s important to consider the advantages and disadvantages of each damping technique and select the one that is most suitable for your application.

Adaptive Control Systems

Adaptive control systems are designed to monitor and adjust the cutting parameters in real-time to optimize machining performance and minimize chatter. These systems use sensors and feedback mechanisms to monitor the cutting conditions and adjust the cutting parameters accordingly. The goal of adaptive control systems is to maintain optimal cutting conditions and prevent the occurrence of chatter.

Adaptive control systems can be particularly useful in high-speed machining applications, where the cutting conditions can vary rapidly and unpredictably. By adjusting the cutting parameters in real-time, adaptive control systems can minimize the risk of chatter and improve machining performance.

Adaptive control systems offer several advantages in CNC machining, including:

- Real-time monitoring and adjustment of cutting parameters

- Increased machining performance and efficiency

- Minimization of chatter and improved surface finish

- Reduced tool wear and longer tool life

However, adaptive control systems can also have some disadvantages, such as:

- Higher cost and complexity compared to conventional machining systems

- The need for specialized software and hardware

- The risk of false alarms or over-correction if the sensors are not calibrated properly

Final Thoughts

Chatter is a common problem in CNC machining that can cause lot of problems. However, there are many tools and techniques available for minimizing chatter and achieving a better surface finish. By understanding the causes and types of chatter and implementing appropriate measures, you can reduce the risk of chatter and improve machining performance.

Remember that each application is unique, and the optimal approach to minimizing chatter may vary depending on the material being machined, the cutting conditions, and the desired surface finish. It’s essential to monitor the cutting process, adjust the cutting parameters as necessary, and follow best practices for tool and machine maintenance.

By implementing these tools and techniques and following best practices, you can minimize chatter and achieve a better surface finish in CNC machining.

Related Posts

- Surface Refinement: Leveraging Bead Blasting for CNC Machining

In the realm of CNC machining, surface quality plays a pivotal role in determining the overall performance and aesthetics of the final product. Leveraging bead blasting as a surface refinement…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…