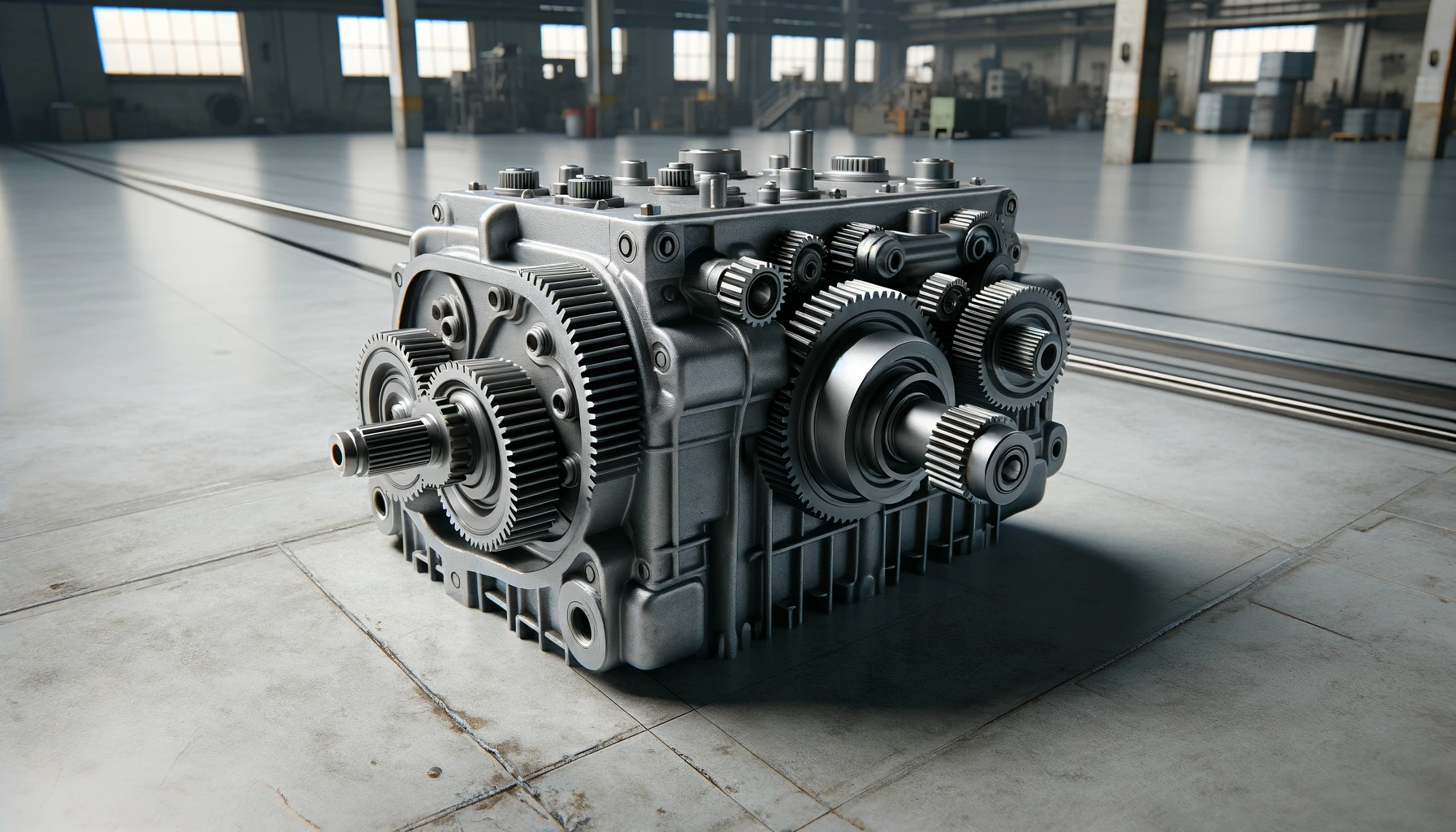

Introduction to CNC Machining Gearboxes

CNC (Computer Numerical Control) machining is a process used extensively in the manufacturing sector to produce precision parts with high accuracy and efficiency. Gearboxes, being a critical component in various machinery, from automobiles to industrial equipment, require exacting standards of precision and durability. The process involves the use of computer-controlled machine tools to shape metal and other materials into the desired form, with gearboxes often requiring complex internal geometries and exacting tolerances to function correctly.To make it easier for customers who need gearboxes to place orders quickly, manufacturers even offer online CNC machining services.

Common Challenges in CNC Gearbox Machining

Machining gearboxes using CNC technology presents a multifaceted set of challenges that can significantly impact the production process and the quality of the final product. The precision required for gearboxes, which are integral to the functioning of a wide array of machinery, necessitates a level of accuracy that can be difficult to consistently achieve. One of the most significant challenges is the machining of intricate gear teeth profiles, which must mesh perfectly to ensure smooth power transmission. The complexity increases with the demand for noise reduction in gear operation, requiring even finer tolerances.

Material selection poses another hurdle. Gearboxes are typically made from materials that are chosen for their strength and durability, such as high-grade steels or advanced alloys. These materials can be challenging to machine due to their hardness and wear resistance, leading to increased tool wear and the potential for tool failure. This not only slows down the manufacturing process but also raises costs due to the frequent need for tool replacement.

Thermal expansion is an additional concern that can affect the dimensional accuracy of CNC-machined parts. As the machining process generates significant heat, both the workpiece and the tool can expand, leading to deviations from the intended dimensions. Managing this requires careful control of machining parameters and cooling techniques, but even with these measures, achieving the necessary precision can be challenging.

Chip evacuation is another issue that can lead to inefficiencies and defects in the machining of gearboxes. The complex shapes and deep cavities involved in gearbox machining can hinder the removal of chips from the cutting area, leading to tool breakage, surface finish defects, and potential damage to the workpiece. Implementing effective chip management strategies, such as the use of high-pressure coolant systems, is crucial but can add complexity and cost to the manufacturing process.

Furthermore, the integration of CNC machining with other manufacturing processes, such as casting or forging, which are often used to create the initial shape of the gearbox, can introduce additional challenges. Ensuring that the CNC machining process is compatible with the tolerances and conditions of these preliminary processes is essential to avoid misalignments or discrepancies in the final product.

Lastly, the demand for custom and specialized gearboxes in certain applications can introduce further complexity into the CNC machining process. Custom designs may require unique tooling or machining strategies, increasing the time and cost associated with the production of each unit. This necessitates a high level of flexibility and innovation in the machining process, as well as a deep understanding of the specific requirements of each application.

Addressing these challenges requires a comprehensive approach that includes the selection of appropriate materials and cutting tools, the careful design of machining processes, and the use of advanced technologies such as adaptive machining and real-time monitoring. By overcoming these obstacles, manufacturers can achieve the high levels of precision and efficiency required for the production of high-quality gearboxes.

Innovative Solutions from China’s Manufacturing Sector

China’s manufacturing sector has been at the forefront of adopting innovative solutions to overcome these challenges. One such example is the use of advanced coatings on cutting tools to extend their life and maintain precision. For instance, a leading Chinese gearbox manufacturer adopted titanium aluminum nitride (TiAlN) coated tools for machining hardened steel gears. This not only reduced tool wear by up to 50% but also improved the surface finish of the gears, enhancing the overall efficiency of the gearbox.

Case Studies: Success Stories of Overcoming Challenges

A notable case study involves a Chinese company specializing in wind turbine gearboxes. They faced significant challenges in machining large, complex gears with high precision. By integrating 5-axis CNC machines and custom-designed cutting tools into their production line, they were able to reduce machining time by 30% while maintaining the tight tolerances required for efficient energy transmission. This not only improved their production efficiency but also significantly reduced the cost per unit, giving them a competitive edge in the market.

Future Trends in Gearbox Manufacturing Technologies

The future of gearbox manufacturing is likely to be shaped by advancements in digital technologies and automation. One promising area is the use of digital twins, which are virtual replicas of physical manufacturing processes. This allows manufacturers to simulate and optimize their machining processes before actual production, reducing the risk of errors and improving efficiency. Additionally, the integration of AI and machine learning algorithms can further enhance the precision and speed of CNC machining by predicting tool wear and automatically adjusting machining parameters in real-time.

Conclusion and Best Practices for Industry Professionals

In conclusion, overcoming the technical challenges in CNC machining gearboxes requires a combination of advanced technology, innovative strategies, and best practices. Industry professionals can benefit from adopting cutting-edge tools and materials, integrating digital technologies into their production processes, and continually optimizing their machining strategies based on real-world data and simulations. By doing so, they can achieve higher efficiency, precision, and cost-effectiveness in gearbox manufacturing, positioning themselves for success in the competitive global market.

Related Posts

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Maximizing Precision: China CNC Machining for Gearboxes

The Role of CNC Machining in Gearbox Manufacturing Gearboxes are integral to the functionality of a wide range of machinery, acting as the cornerstone of power transmission systems. The role…