Introduction to CNC Machining

The technology of Computer Numerical Control (CNC) machining has revolutionized industrial manufacturing processes. At its core, CNC machining harnesses the power of computers and advanced software for precise control over tools and machinery used in production stages. It’s widely applicable across many industries, offering unparalleled precision, consistency, and efficiency. Specifically, when it comes to steel manufacturing, CNC machines play a pivotal role.

Application of CNC Machine in Steel Manufacturing

The use of CNC machining extends significantly into steel manufacturing. Its ability to handle hardened materials makes it ideal for various applications such as:

- Molding and Shaping: A CNC machine molds and shapes steel according to specific measurements with impeccable accuracy, often within microns.

- Cutting: With its high-powered lasers or plasma torches, these machines are capable of cutting through even the toughest variety of steel, including stainless steel and carbon steel.

- Drilling: CNC drills execute holes into workpieces more accurately than any manual methods could ascertain.

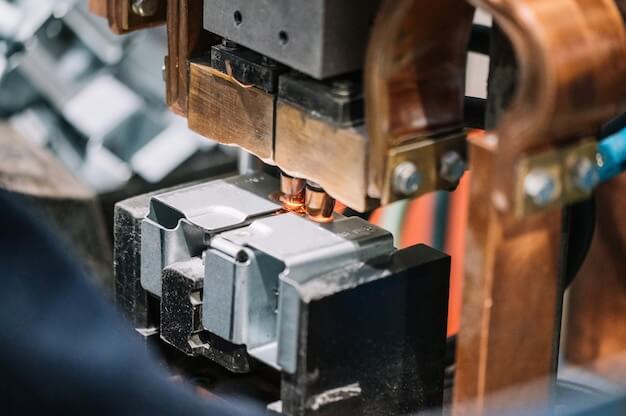

- Welding: Some manufacturers utilize CNC machines in welding processes due to their ability to ensure minimal error and maintain the highest levels of safety.

All these diverse uses underscore the critical role CNC machines play in the realm of steel manufacturing, confirming their place at the foreground of this industry.

Understanding Hardened Steel and Its Characteristics

Hardened steel is characterized by its increased toughness, durability, and wear resistance. It’s formed through a process of heat treatment that significantly increases the strength properties of the original low-carbon or medium-carbon steel. The heating temperature along with cooling rate are crucial parameters determining the final hardness, which can typically hover around 60 HRC (Rockwell scale). This makes hardened steel highly ideal for various CNC machining applications in manufacturing.

The benefits of using hardened steel extend to include excellent longevity, ability to withstand high levels of stress, and heightened performance under adverse conditions (like high temperatures). Yet, these manufacturing advantages come strapped with challenges; one primary issue being machinability. Due to its tough nature, this material often demands more time and resources during the machining process, affecting production costs, speed, and tool life span negatively. Additionally, achieving precision in dimensions and surface quality require careful handling and specific techniques.

Techniques for CNC Machining of Hardened Steel

When machining hardened steel, it’s essential to consider the following techniques:

- Use specialized cutting tools designed for hard materials.

- Implement slow and consistent cutting speeds to prevent tool wear.

- Utilize high-pressure coolant systems to control heat and extend tool life.

Essential Tips for Effective Manufacturing with Hardened Steel

The process of CNC machining hardened steel requires specific strategies and precision to ensure effective manufacturing. Implementing the right strategy when dealing with hardened steel is crucial due to its hardness rating that often presents unique challenges in production. This includes selecting appropriate cutting tools made from robust materials such as carbide or polycrystalline diamond which are capable of handling high temperatures and pressures produced during the process.

- Selecting an ideal cutting tool: Tools made from Carbide or Polycrystalline Diamond (PCD) can withstand the rigorous conditions of machining hardened steel, ensuring better performance and durability.

- Determining correct feed rate and speed: Each tool has a unique optimal speed and feed rate depending on its composition and dimensions. For instance, solid carbide end mills function at higher speeds yet lower feed rates compared to High Speed Steel (HSS).

- Maintenance Practices: Regular sharpening of cutting tools will reduce wear and tear, maintaining efficiency in operation while extending their lifespan.

Therefore, understanding these factors can enhance productivity and improve the quality of output when working with hardened steel. For example, a manufacturer could optimize their manufacturing operations by investing in durable cutting tools and adapting the proper maintenance practices. By monitoring the usage of each tool, early signs of wear can be identified and rectified before they lead to costly machine damage or poor-quality products.

Impact of CNC Machining Hardened Steel on Overall Manufacturing Efficiency

The implementation of Computer Numerical Control (CNC) machining techniques for hardened steel significantly amplifies the manufacturing efficiency. The prime reason lies behind its precision, speed, and consistency that complements traditional methods, thereby reducing manual labor and errors considerably.

- Precision: CNC machining is highly accurate and can create complex shapes that are virtually impossible with conventional approaches. This results in a lesser number of rejected parts, leading to cost-efficiency.

- Speed: Compared to manual interventions required by other methods, once set up properly, CNC machines work quicker without pauses but consistent production quality.

- Consistency: CNC Machines can function uninterruptedly over an extended period while maintaining consistent accuracy. Thus, there’s always a reliable output rate which leads to more predictable delivery times and scheduling.

In the long run, manufacturers who correctly apply these CNC machining techniques will observe a significant increase in productivity, lower waste material, reduced labour costs, and improved competitiveness in the market proving why it makes sense to invest in this technology for efficient production of hardened steel components.

Related Posts

- Using CNC Machining to Fabricate Lightweight Metal and Remove Chrome From Metal( cnc machining services china Dana)

CNC (Computer Numerically Controlled) machining is an essential process in the manufacturing domain. With its precision, adaptability, and extensive applications, many industries rely on it for fabricating highly complex parts…

- Efficient CNC Machining of Lightweight Metal and Chrome Removal( cnc machining services china Atwood)

Computer Numerical Control (CNC) machining is a modern manufacturing process used in various industries, frequently dealing with lightweight metals or needing to remove chrome from metal surfaces. This article will…

- Material Flexibility in CNC Machining: Engineering Soft Materials for Complex Parts

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and repeatability that are unmatched by manual processes. At its core, CNC (Computer Numerical Control)…