Introduction to Renewable Energy

Rewindable energy is inherently replenished on a human timescale, meaning it harnesses natural elements that naturally renew themselves. These sources traditionally include sunlight, wind, rain, tides, waves, and geothermal heat. The importance of renewable energy can’t be understated in today’s world. The utilization of renewable energy presents numerous benefits, both for individuals and the planet as a whole.

- Sustainability: The foremost benefit is its sustainable nature. Unlike conventional energy sources such as coal and petroleum, renewable energy never depletes. It provides an enduring energy supply that could serve humanity for the foreseeable future.

- Environmentally Friendly: In stark contrast with fossil fuels which release harmful pollutants when burned, renewable energy generation entails negligible emission, making it environmentally friendly.

- Economic Advantages: Its economic advantages are ample. It often requires substantial initial investment but once achieved, the running cost is minimal since it relies on freely available natural resources.

- Energy Independence: Countries that depend heavily on imported fossil fuels can achieve energy independence by promoting renewable energy usage. This will also reduce vulnerabilities associated with fluctuations in fuel prices and geopolitics.

In conclusion, renewable energy holds immense potential to revolutionize our energy system and address many challenges we currently face.

An Overview of CNC Machines

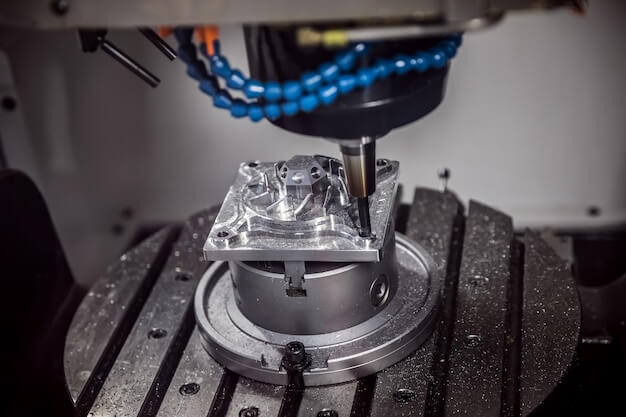

A Computer Numerical Control (CNC) machine is an automated equipment utilized in the manufacturing industry to create intricate and accurate parts with high precision. It operates under a coded programmed instruction without the need for manual control, reducing human errors considerably. The role and function of CNC machined components include:

- Scalable production: They offer scalability for mass production while ensuring accuracy across all manufactured units.

- Flexibility: Being programmable machines, they can suitably switch between different production applications.

- Efficiency: These machines efficiently perform complex cuts at high-speeds that wouldn’t otherwise be possible manually.

- Safety: Since they operate independently, thus, minimizing risks associated with manual machining processes.

In essence, CNC machines revolutionize renewable energy development by effortlessly crafting necessary components like wind turbine blades or solar panel pieces using various materials, setting new standards in the manufacturing sector.

Detailed Analysis on CNC Machining in Solar Panel and Wind Turbine Production:

- Step 1: CNC machining plays a crucial role in the production of components for solar panels and wind turbines, ensuring the precise manufacturing of parts essential for renewable energy systems.

- Step 2: This process enables the creation of intricate and durable components that contribute to the efficiency and reliability of solar panels and wind turbines.

- Step 3: To explore CNC machining services for renewable energy production, consider utilizing online CNC service for efficient and high-quality manufacturing solutions.

Impact of CNC Machining on Efficiency and Cost-effectiveness in Renewable Energy Sector

CNC machined components are transforming the renewable energy sector by enhancing efficiency and cost-effectiveness. One of the significant impacts has been material waste reduction. Traditional manufacturing processes often result in excess scrap, but with precision CNC machining, intricate designs can be cut from a single piece of material leading to minimal wastage. The high-precision nature of CNC machining translates into savings when it comes to materials procurement, handling, and disposal.

In addition to cost-saving benefits, adopting CNC practices enhances part accuracy, consequently reducing errors and increasing overall process efficiency. A typical example is the wind energy sector where highly accurate parts such as blades, hubs, and nacelle components are essential for optimal performance. With CNC machining, each one of these components can be produced accurately every time, minimizing variances that could compromise system effectiveness.

- Reduced Waste: CNC machining streamlines resource utilization by working directly from digital models and recycling material offcuts.

- Increased Accuracy: By using digital templates, CNC machines ensure all parts line up correctly resulting in reduced error rates and rework, thereby improving operational efficiency.

Future Trends in Renewable Energy Field with Influence of CNC Technology

The application of CNC (Computer Numerical Control) technology is predicted to advance exponentially within the renewable energy sector, particularly in harnessing hydro and geothermal power. The precision offered by this technology improves efficiency and reduces wastage, making it indispensable for future developments. With CNC technology, there would be better design flexibility, enabling engineers to explore innovative designs that maximize performance.

- Predictive Analysis on Advancement of CNC Application: Modern production methodologies employed in creating equipment for harvesting hydro or geothermal energy increasingly rely on CNC machining due to its high accuracy and ability to fabricate complex components easily. This indicates a growing trend where CNC’s importance can’t be overlooked in future energy solutions.

- Improvements in Renewable Energy Apparatus: Traditional methods often restrict the improvements that can be made to increase an apparatus’s lifespan or capacity. However, the sophistication of CNC machining implies great potential for creating hard-wearing, high-performance renewable energy systems. By controlling production processes down to intricate details, CNC machining provides unprecedented opportunities for improving the structural durability and resilience of various tracts of renewable energy generation apparatus.

Related Posts

- Unraveling the World of CNC Machined Plastic Parts(CNC machined plastic parts Mabel)

Modern innovations have taken traditional manufacturing methods to new heights. One such innovation that stands out is Computer Numerical Control (CNC) machining, a process used extensively in various industries from…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…

- The Role of CNC Machining in Renewable Energy: Material Choices for Durability and Efficiency

Introduction to CNC Machining and its Relevance in Renewable Energy CNC (Computer Numerical Control) machining, a technology rooted in the manufacturing space, involves the use of computers to drive and…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- Strategies for Enhancing Thermal Conductivity in CNC Machined Parts

The Importance of Thermal Conductivity in CNC Machined Parts In the sphere of CNC machining, thermal conductivity is an extremely vital factor. It has crucial effects on both performance and…