CNC Aluminum Machining Services

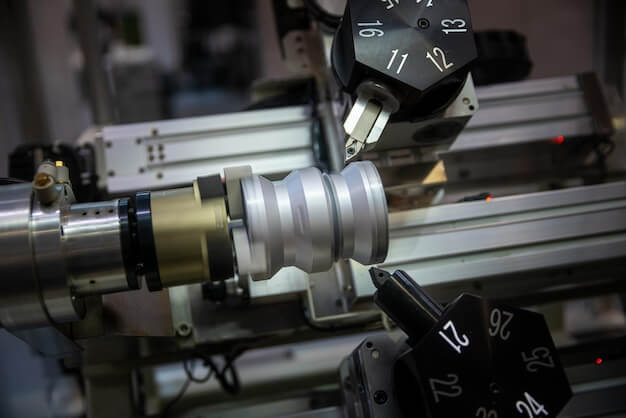

In the current manufacturing landscape, CNC aluminum machining services play a pivotal role. CNC which simply translates to ‘Computer Numerical Control’, is an advanced technique used in creating precision parts from aluminum and other materials. The process involves using computer-generated designs to control machine tools such as lathes, mills, grinders, and routers. Here, aluminum blocks are designed into specific shapes based on 3D CAD models meticulously controlling rotations of multi-point cutting tool numerically.

- CAD Design: This forms the blueprint for the entire process.

- Cutting Tools: Various tools like mills, and grinders are set into motion based on this design.

- Aluminum Blocks: They serve as raw material that undergoes transformation under these tools.

This overall technique provides unprecedented accuracy, efficiency, and versatility while reducing waste & costs. It has applications in many industries such as aerospace, automotive, medical devices, energy, and more.

Understanding CNC Machining Services

Computer Numerical Control (CNC) is a concept that enables precise control of machine tools with the use of computer software. Through this system, every intricate action from spinning to moving to cutting can be meticulously controlled, eliminating human error and significantly increasing precision. Simply put, CNC machines work by converting computer-aided design (CAD) files into numeric mathematical instructions, known as G-code, which governs the behavior of the tool.

CNC machining surpasses traditional manufacturing methods in several ways. For one, permanent fixtures aren’t necessary for parts positioning which reduces production time. Secondly, it’s suitable for both low-volume prototyping and high-volume production runs due its versatility and repeatability. Conclusively, the advantages of CNC processing provide improved speed, accurateness, scalability and cost-effectiveness compared to conventional techniques.

- Description of CNC: A system offering precise control of machineries using computers.

- How CNC works: Conversion of CAD files into controlling instructions or G-code.

- Applications and advantages: Suitable for various manufacturing volumes, offers speed, accuracy, scalability, efficiency and cost benefits over traditional systems.

Deep Dive into Aluminum as a Material for Machining

Aluminum is widely recognized in the manufacturing industry due to its unique properties that make it an ideal material for CNC machining. Its high malleability and machinability allow for complex shapes to be formed without requiring intensive tooling processes. Moreover, aluminum has great thermal conductivity and electrically non-magnetic nature which provide further advantages in the machinery sector.

- Malleable yet Durable: Aluminum’s composition allows it to be easily cut or shaped while maintaining enough strength to withstand typical operational stresses, facilitating cost-effective production of complex parts.

- Thermal Conductivity: Aluminum’s excellent thermal properties make it suitable for applications where heat dissipation and resistance are crucial, such as automotive and electrical industries.

- Non-Magnetic Nature: When dealing with sensitive electronics or magnetic fields, using aluminum assures there will be no disturbance caused by induced magnetism as encountered with other metals.

- Lightweight: In comparison to metals like steel or brass, aluminium’s lighter weight aids in enhancing fuel efficiency when utilized in components of transportation vehicles.

In conclusion, the properties mentioned above render aluminum a versatile material, particularly beneficial for sectors demanding precision-driven, efficient, and innovative manufacturing solutions via CNC machining.

Advanced techniques in CNC aluminum machining:

- Precision Tooling: Utilizing advanced cutting tools and techniques to achieve intricate designs and precise dimensions in aluminum machining.

- High-Speed Machining: Implementing high-speed machining strategies to optimize the production process and improve efficiency in aluminum CNC machining.

- Specialized Finishing: Employing specialized surface finishes and treatments to enhance the appearance and functionality of CNC machined aluminum parts.

Produced Parts and Their Perfection Due to CNC Aluminum Machining

CNC aluminum machining is widely used in various industries to produce an extensive range of parts with unparalleled precision. Some common parts made via this method include car parts, electronic device components, medical equipment, aerospace parts, and kitchenware. The advanced techniques flawlessly cut, mold and shape the aluminum into desired forms, ensuring that every detail is perfected.

- Car Parts: In the automotive industry, for example, perfect pistons are created using CNC machines which ensures superior strength and durability.

- Electronics: Components such as casings, heatsinks, or brackets in electronics are manufactured accurately using these techniques, contributing to efficient devices.

- Medical Equipment: This state-of-the-art technology enables precise creation of lifesaving instruments like surgical tools and implants.

- Aerospace Parts: Complex shapes required in aerospace technologies can be produced with ultimate precision thanks to CNC machines

- Kitchenware: Perfectly engineered kitchenware handles and utensils demonstrate how ingenuity meets practicality in everyday life.

The role of advanced techniques is indispensable in delivering these flawless results. Through rigid programming, material compatibility studies, simulation, multi-axis operations, timely adjustments, & optimal cutting speed, one can achieve the most complex geometries with superb finishes and exacting tolerances. Hence, the mix of sophisticated machinery and its appropriate handling by versatile software facilitates the production of top-tier parts through CNC aluminum machining.

Conclusion: The Significance of CNC Aluminum Machining Services in Today’s Manufacturing

In review, we have significantly highlighted the crucial role played by Computer Numerical Control (CNC) aluminum machining services in contemporary manufacturing. Precision production and flexibility enable manufacturers to produce complex parts with high accuracy as a result of versatile operation modes in these advanced systems.

- Firstly, their steadfast demand in sectors like aerospace, automotive, or electronics, relates primarily to the service’s capability to deliver industry-standard parts from designs within short turnarounds.

- Secondly, this revolutionary technique reduces human error since computers govern these operations, thus reassuring consistent excellence in part manufacture. Finally, versatility which allows for quick alteration of design specifications further highlights its importance.

In essence, CNC aluminum machining services represent an indispensable cornerstone in modern manufacturing owing to their cutting-edge approach towards precision, efficiency and adaptability.

Related Posts

- Unlocking New Possibilities in CNC Machined Titanium Medical Devices

Introduction to CNC Machined Titanium Medical Devices The prevalence of CNC machined titanium medical devices in the healthcare sector demonstrates their immense significance and usefulness. This technology furnishes an essential…

- Hastelloy vs. Stainless Steel in Chemical Processing Equipment: CNC Machining Perspectives?

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: An Introduction In the realm of chemical processing equipment, two commonly used materials include Hastelloy and stainless steel. Hastelloy, a reputed superalloy…

- Bronze Rivet Technology in CNC Machining

Bronze type that can process Rivet Phosphor Bronze Characteristics: High strength, excellent wear resistance, good elasticity. Applications: Springs, bearings, and parts requiring high wear resistance and elasticity. Tin Bronze Characteristics:…