Introduction to CNC Machining and its Aesthetic Significance in Consumer Products

CNC Machining, known formally as Computer Numerical Control Machining, serves a significant role in producing consumer products. This technique uses computers to control machine tools for an accurate and efficient production process. The focus of this article touches upon the crucial use of aesthetic materials in CNC machining. Due to advancements in technology, consumers now gravitate towards products with superior quality and appealing visual aesthetics. Therefore, manufacturers utilize various suitable aesthetic materials in CNC machining to meet these demands.

- The importance lies not only in crafting functional products but also ones that are visually pleasing.

- Different materials such as composites , metals or plastics can be used based on the nature of the end product.

- Accurate selection of materials plays a vital role in determining aspects like durability, cost efficiency and perceived value.

In conclusion, the evolution of the consumer market highlights the increasing significance of the intersection between functionality and aesthetics, positioning CNC machining right at this crossroad.

Understanding CNC Machining

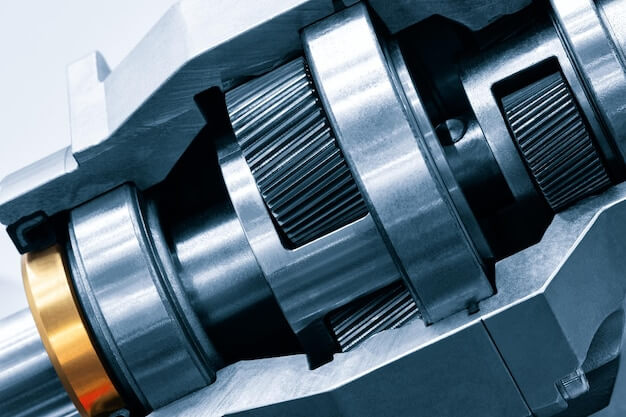

The art of CNC machining can be aptly compared to a computer printer for its functionality. The term ‘CNC’ stands for Computer Numerical Control and, in essence, it’s an automated control of machinery via encoded data inputs. Just as the printer uses digital files to map and generate physical copies, CNC machines work similarly. They interpret 3D design plans or CAD drawing instructions to carve shapes from sheets of materials with extreme precision.

There are several key benefits that make CNC machining indispensable in consumer products production:

- Precision: Unlike manual machining, CNC machining allows for extremely accurate repetition of cutting operations closely following the programmed blueprints. This ensures an unparalleled degree of detail and complexity which could not be achieved otherwise.

- Speed: Operating at faster speeds than human-operated machinery while maintaining high capture rates, CNC machines inherently increase productivity levels significantly.

- Automation: By using digitally guided directions, CNC machines eliminate human error and issues associated with manual labour like fatigue and inconsistent quality. As automation increases, overall manufacturing costs decrease.

Role of Materials in CNC Machining

Materials play a crucial role in CNC machining, especially when it comes to creating aesthetic consumer products. Here is a step-by-step analysis of the role of materials in CNC machining:

1. Visual Appeal:

- Materials used in CNC machining for consumer products must offer visual appeal and attractive aesthetics.

- The chosen material should have the desired texture, color, and surface finish to create visually appealing products.

- Additionally, the material should allow for easy polishing, painting, or finishing to achieve the desired appearance.

2. Durability and Functionality:

- While aesthetics are important, the material must also provide durability and functionality.

- It should be able to withstand the intended use and any environmental factors that the product may encounter.

- Choosing materials with the right combination of strength, toughness, and resistance to wear and tear is crucial for long-lasting consumer products.

3. Material Selection and Design:

- The selection of materials for CNC machining is closely tied to the design of the product.

- Design considerations, such as part weight, heat resistance, electrical conductivity, and magnetic requirements, influence the choice of materials.

- Understanding the design requirements and the properties of different materials helps in selecting the most suitable material for the desired aesthetic and functional outcome.

4. Expert CNC Machining Services:

- To ensure the successful realization of aesthetic consumer products through CNC machining, it is essential to work with expert CNC machining services.

- Services like our online CNC service provide the expertise and precision required to bring your design to life.

- With advanced technologies and a focus on precision machining, these services can help achieve the desired aesthetic and functional qualities of your consumer products.

The role of materials in CNC machining is vital for creating aesthetic consumer products that are visually appealing, durable, and functional. To bring your design to reality with precision and expertise, you can rely on our online CNC service.

Popular Aesthetic Materials Used in CNC Machining

In the art of CNC machining, a variety of materials are utilized to achieve both form and function for various consumer products. These include an array of metals and plastics each with its unique advantages and applications.

Metal

The most commonly used metals in CNC machining include aluminum, brass, and bronze. Aluminum is favored for its light weight, high strength, and corrosion resistance making it ideal for products like automotive parts or aircraft components. Brass exhibits excellent machinability, good wear resistance, and an attractive aesthetic appeal that lends itself well to decorative items or instruments such as clocks and musical tools. Bronze offers superior load-carrying capacity, making it popular in manufacturing bushings, gears, and similar components. Each metal, however, also has potential disadvantages: aluminum can be relatively soft, brass may require protective coatings to prevent tarnishing, and bronze could be expensive due to its copper content.

Plastic

Popular plastic options encompass ABS (Acrylonitrile Butadiene Styrene), polycarbonate, and PEEK (Polyether Ether Ketone). ABS, known for its toughness, shock resistance, and affordability, sees wide use in the creation of toys, automotive components, and equipment housings. Polycarbonate stands out because of its incredibly high impact resistance and optical clarity, making it desirable in eyewear, medical devices, and safety equipment. As for PEEK, its high temperature stability and chemical resistance render it valuable in medical implants, piston parts, and cable insulation. While these plastics afford many benefits, users should consider their drawbacks too: ABS may show lower performance at high temperatures, polycarbonate can scratch easily if not given a protective coating, and PEEK might cost significantly more than other plastics due to its specialized properties.

How Design Influences Material Choice in CNC Machining

In the art of CNC machining, the design plays a significant role in determining the material choice for consumer products. Certain intricate designs necessitate more malleable materials that can be manipulated with high precision without compromising the overall integrity and finished look of the product. For example, complex geometrical designs may require materials like aluminum or soft plastics which are easier to machine and maintain fine details.

The aesthetics also have a substantial influence on the decision-making process. The desired color, texture, look, and feel can guide the selection towards certain materials over others. Factors such as:

- Durability: Materials like stainless steel can offer a sleek, modern look with good resistance to wear and corrosion.

- Color Variety: Polymers come in various colors and finishes, enabling designers to meet specific aesthetic requirements.

- Texture and Finish: Some materials like wood can provide a unique tactile experience and artisanal charm not replicable by other materials.

All these factors intertwine, shaping the identify of the final product, its functionality, market appeal, and longevity based on chosen aesthetics and related material properties.

The Future of CNC Machining and Aesthetic Materials

Emerging trends in the world of CNC machining project a future marked by increasing use of recycled and eco-friendly materials. This not only reaffirms industries’ commitment to sustainability but also allows for the creation of consumer products that are as aesthetically pleasing as they are environmentally conscious. Beyond mere functionality, these materials reflect an appreciation for beauty and craftsmanship within everyday objects.

- Recycled plastics, metals, and wood can now be transformed through precise automation into detailed designs, made possible through advancements in CNC technology.

- Eco-friendly biopolymers, often derived from renewable plant-based sources, offer another avenue for innovation whilst curbing reliance on traditional petroleum-based materials.

Awareness of these considerations enriches our understanding and value of seemingly ordinary items, underlining just how widespread the influence of CNC machining is within society. More than simply shaping physical goods, such technological applications embody larger cultural shifts towards responsible consumption. The integration of sustainable practice with product aesthetics promises an exciting frontier for CNC machining.

Related Posts

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Optimizing CNC Machining with Hybrid Materials: Benefits and Challenges

Introduction: CNC Machining and the Role of Hybrid Materials CNC machining, short for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory…

- Are Polymer Composites the Future of Lightweight Machining?

Introduction to Polymer Composites and Lightweight Machining Polymer composites, often simply referred to as composites, are engineered materials made from two or more constituent materials with significantly different physical or…