Introduction: The Intersection of Smart Materials and CNC Machining Processes

Smart materials, also known as intelligent or responsive materials, have the inherent ability to alter their respective physical properties in response to changes within their environment. This capability makes them remarkably suitable for the implementation in a host of industries and operations, including Computer Numerical Control (CNC) machining processes. By definition, CNC machining processes encompass various subtractive manufacturing methods, typically run by computer software that controls each precise movement of factory tools and machinery.

- The utilisation of smart materials in these processes introduces an unprecedented level of adaptability and automation potential that can significantly optimise efficiency, enhance production precision, diminish human error, alongside reducing labor-intensive tasks.

Understanding CNC Machining Process

The CNC machining process is a highly efficient and precise method of manufacturing parts using computer-controlled machines. Let’s explore the steps involved in the CNC machining process:

1. Designing the Part:

The first step in the CNC machining process is to create a detailed design of the part using computer-aided design (CAD) software. The design includes the dimensions, geometry, and specifications of the part.

2. Programming:

Once the design is complete, the next step is to program the CNC machine. This involves converting the design into machine-readable code, known as G-code. The G-code contains instructions for the machine’s movements, tool paths, and machining operations.

3. Material Selection and Preparation:

After programming, the appropriate material for the part is selected. CNC machining can work with a wide range of materials, including metals, plastics, and composites. The material is then prepared by cutting it into the desired size and shape, ready for machining.

4. Machine Setup:

The CNC machine is set up by installing the necessary cutting tools, fixtures, and workholding devices. The machine is calibrated to ensure accuracy and precision in the machining process. The cutting tools are carefully selected based on the material and desired machining operations.

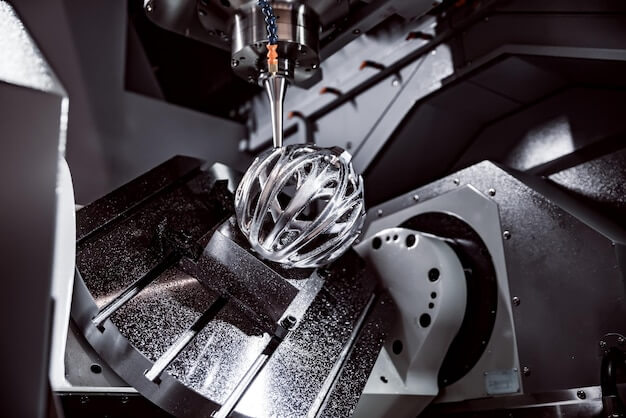

5. Machining Operations:

With the machine set up, the CNC machining process begins. The machine follows the programmed instructions to perform various machining operations, such as milling, turning, drilling, or grinding. These operations remove excess material and shape the workpiece according to the design specifications.

6. Quality Control:

Throughout the machining process, quality control measures are implemented to ensure the accuracy and quality of the machined parts. This may involve using measuring tools, such as calipers or coordinate measuring machines (CMM), to verify dimensions and tolerances.

7. Finishing and Post-Processing:

Once the machining operations are complete, the machined parts may undergo additional finishing processes, such as deburring, polishing, or surface treatments, to achieve the desired surface finish and appearance.

8. Inspection and Packaging:

The final step in the CNC machining process is the inspection of the finished parts to ensure they meet the required specifications. The parts are then carefully packaged and prepared for shipping or further assembly.

Understanding the CNC machining process is essential for successful manufacturing. For professional CNC machining services and expert advice on the process, you can rely on our online CNC service.

Application of Conventional Materials in CNC Machining

The use of traditional materials in Computer Numerical Control (CNC) machining processes is an established practice. These materials encompass a broad variety including but not limited to, aluminium, stainless steel, brass, copper and various plastic polymers. Each material offers its unique properties that make it suitable for specific applications. For instance, Aluminium’s high machinability and good thermal conductivity are advantageous for heat-sensitive products, while plastics like ABS or Nylon excel due to their durable yet lightweight nature.

- Aluminium – High machining capability and effective heat management

- Stainless Steel – Strong and corrosion resistant

- Brass/Copper – Easily malleable with the excellent electrical conductivity

- Plastic Polymers (ABS/Nylon) – Hard-wearing, lightweight, and flexible

Despite their widespread employment, these conventional materials come with certain limitations in the context of advancing CNC technology. Considerations such as surface roughness after machining, energy consumption during processing, waste generation, and incapacity to adapt according to external environments can impede efficiency and precision outcomes desired from advanced CNC machining processes.

The Advent of Smart Materials in the Manufacturing Industry

Smart materials, recognized for their ability to react and adapt to changes in their environment such as alterations in temperature, light, or pressure, are making remarkable strides in the realm of manufacturing, particularly CNC machining processes. These dynamic substances can return to their original state after these environmental conditions have been altered, amplifying the handling precision of CNC machines. Various classifications of smart materials exist, each with its unique characteristics and application potential.

- Piezoelectric materials: Exhibit an electrical response when mechanical stress is applied and vice versa. They’re used extensively in precision-driven applications like ultrasonic transducers and automotive sensors.

- Magnetostrictive materials: Alter their shape under the influence of a magnetic field, and they find practical utility in industrial transformers and actuators.

- Shape Memory Alloys (SMAs): Have the capability to memorize their original shape and can revert back to it even after undergoing massive deformations. SMAs serve indispensable roles in sectors such as aerospace and robotics due to this property.

- Electro-rheostatic and Magneto-rheostatic materials: Under electrical or magnetic stimulus they experience drastic changes in viscosity enabling control of motion which is crucial in vibration damping systems.

In sum, the advent of smart materials opens up new paradigms in manufacturing technology, especially with regards to enhancing efficiency, accuracy, and productivity of CNC Machining Processes. Understanding these smart materials helps us acknowledge their capabilities and explore future possibilities where their revolutionary impact becomes much more profound.

Smart Materials and Their Potential for Future CNC Machining Processes

Innovations in materials science have ushered the advent of smart materials, which hold immense potential in revolutionizing future Computer Numerical Control (CNC) machining processes. Smart materials are marked by their responsiveness to environmental changes such as temperature, humidity, or pressure. Herein lies their relevance to CNC processes – the ability of these automated machines to adapt intuitively to fluctuating conditions can significantly enhance precision, reduce waste, and streamline production lines.

Delving into specifics, let’s consider the instance of Shape Memory Alloys (SMA). SMAs “remember” their original form, enabling them to revert back upon exposure to a stimulus like heat. In a CNC context, this implies that tools made from SMAs could potentially self-correct any deviations during the machining process, boosting accuracy without additional calibration requirements. The use-case underscores how smart materials may increase efficiency while maintaining high quality in future CNC operations.

- Relevance: The symbiotic alignment between the responsive nature of smart materials and the adaptability required in evolving CNC operations establishes its importance.

- Potential Benefits: Enhanced precision, minimized waste, streamlined production sequences thanks to fewer calibration needs.

- Example:Use of Shape Memory Alloys in CNC machinery for self-correction of tool path deviations, eliminating the need for constant adjustments.

Challenges and Possible Solutions in Incorporating Smart Materials in CNC Machining

The integration of smart materials into the realm of Computer Numerical Control (CNC) machining presents a set of unique challenges. Major potential obstacles include high costs associated with the acquisition and operation of these advanced materials, complexities pertaining to their manipulation during fabrication processes, as well as technical difficulties related to programming machines for optimum precision and efficiency.

To effectively address these concerns, multiple viable solutions have been proposed. Firstly, continuous advancements in technology present opportunities for cost reduction through increased availability and improved methods of production. One example is Additive Manufacturing Technology, which has shown promise in reducing production costs particularly for complex geometries that are costly with traditional means. Secondly, ongoing research in material science provides insights about innovative ways of handling smart materials to ease the complexity of their deployment in CNC machining.

Lastly, better understanding of how to leverage software optimisation tools can dramatically improve machine programming thus promoting efficiency. In conclusion, while the incorporation of smart materials in CNC machining comes with several hurdles, innovative technological approaches constitute encouraging prospects for overcoming these challenges.

Conclusion: Impact of Smart Materials on the Future of CNC Machining

The integration of smart materials into CNC machining is an important topic to ponder, given their potential transformative influence for future processes. Highlighting its significance, these innovative materials could revolutionize manufacturing techniques and produce higher quality end products.

- Smart materials can provide self-correction features to improve precision in machining tasks. This would lower the instances of errors and waste, enhancing efficiency within production lines.

- These materials also offer promising opportunities for sustainable machining with energy harvesting capabilities. Thus, embracing smart materials might lead to greener manufacturing methods, making industries more environmentally friendly.

- Moreover, advancements in smart material science may open new doors to novel applications not currently feasible with traditional materials. It could potentially enable creating complex geometries or microstructures with superior properties.

In conclusion, while we’ve barely scratched the surface of what’s possible, it’s clear that the integration of smart materials into CNC machining can have a significant impact on the industry. The progressive evolution through smart materials will continue transforming the conventional approach towards manufacturing, broadening horizons for future CNC machining processes.

Related Posts

- The Future of CNC Machining: Smart Materials and Their Applications

CNC Machining: An Introduction and its Significance in Industrial Manufacturing The principles of Computer Numerical Control (CNC) machining, an automated manufacturing technology that uses pre-programmed computer software to control machinery…

- CNC Machining: Understanding Materials, Processes and Techniques( rivets Nora)

When it comes to Computer Numerical Control (CNC) machining processes utilised in manufacturing industries worldwide, there’s an expansive range of materials, procedures and techniques that play a crucial role. These…

- Precision Aluminum Machining for Aerospace: Custom CNC Services

Precision Aluminum Machining for Aerospace: Custom CNC Services In the world of manufacturing, precision aluminum machining plays a pivotal role, particularly in aerospace industries where superior precision is required. As…