Introduction to Injection Molding

Injection molding is a predominant manufacturing process used to create plastic parts by injecting molten material into a specific mold shape. This technique allows for the mass production of identical items with exceptional precision and repeatability. The injection molding procedure involves several key steps: first, polymer granules are fed into a heated barrel where they melt; then, the liquid plastic is injected into the mold cavity under high pressure; next, it cools and solidifies taking on the desired form; finally, the part is ejected from the mold once it has fully cooled and hardened. This highly efficient method is widely utilized for various applications due to its ability to produce complex shapes with minimal waste.

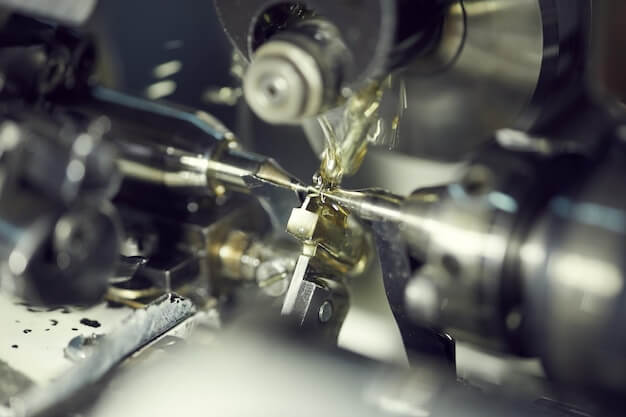

The Procedure of Injection Molding

Injection molding starts with the preparation, where a specific mold is designed and crafted to shape the desired product. Concurrently, an appropriate material—commonly a thermoplastic or thermosetting polymer—is chosen based on its properties, such as strength, flexibility, and resistance to heat and chemicals. The selected plastic granules are then fed into the machine’s hopper and directed towards the heating barrel, where they are melted under controlled temperatures. This molten material is forcibly injected into the prepared mold through a nozzle using high pressure. Once inside the mold cavity, it begins to cool and solidify to adopt the intended configuration of the part. After sufficient cooling time, the newly formed plastic component is ejected from the mold. In some cases, further post-processing like trimming excess material or painting may be necessary to finish the product. Overall, efficient coordination of these steps ensures consistent quality and functionality of injection molded parts.

Advantages of Injection Molding

Injection molding excels as a manufacturing process due to its ability to scale up for mass production while maintaining precision and repeatability. This method is capable of producing complex shapes with a high level of detail, which otherwise would be difficult or expensive to replicate using other fabrication techniques. A notable advantage lies in its material efficiency; the injection molding process minimizes waste by injecting precise amounts of molten material into tightly controlled mold cavities, ensuring that only what is needed to form the part is used. The consistency afforded by this approach not only saves on materials but also streamlines production, making it an economically advantageous choice for large-scale manufacturing.

Injection Molding Applications in Various Industries

Injection molding is a versatile manufacturing process employed across different industries to produce a variety of components with precision and efficiency. Consumer electronics benefit from this technique through the creation of durable phone cases and ergonomic television controllers that are essential for daily use. In the automotive sector, injection molded parts such as impact-resistant bumpers and complex dashboards play critical roles in vehicle safety and aesthetics. The medical field relies on injection molding to produce sterile syringes and intricate surgical components, where exact dimensions and reliability are paramount. Furthermore, the packaging industry utilizes injection molding for crafting secure bottle caps and robust containers, ensuring products are stored safely and are easy to distribute. Each of these applications demonstrates the integral role of injection molding in producing functional and specialized items that meet the demands of today’s market.

Related Posts

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a high-precision manufacturing process used in producing miniature and intricate plastic parts. This procedure, employing specialised machines with high-pressure moulding capabilities…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is an advanced manufacturing technique that miniaturizes traditional injection molding processes. The principle of micro injection molding revolves around producing tiny, intricate…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with precision. The process involves injecting…