Introduction to Titanium CNC Machining and its Significance in Aerospace and Medical Industries

Titanium Computer Numerical Control (CNC) machining utilizes advanced computer systems to control and monitor the movements of a machine. In this case, titanium is cut into precise parts that are incredibly crucial for various applications. This process excels particularly in the aerospace and medical industries. For instance, in the aerospace industry, the lightweight yet strong nature of titanium makes it a prime resource for crafting durable aircraft parts which not only bear extreme environmental conditions but also maintain overall performance efficiency. Meanwhile, in the medical field, the biocompatibility qualities of titanium make it essential for surgical instruments and bodily implants – ensuring longevity and preventing adverse reaction in patients. Both sectors, thus, greatly benefit from the precision and replicability guaranteed by the CNC machining process.

Advantages of Titanium CNC Machining

The primary advantages of titanium CNC machining can be attributed to the unique properties of titanium as a material. To begin with, the toughness of titanium provides exceptional durability, ensuring products made from it have enhanced longevity. This is particularly critical in industries such as aerospace and medicine where component reliability is paramount.

Another vital advantage of using titanium is its lightweight nature. For aerospace components, weight reduction without compromising strength is key to achieve efficiency, reduce fuel consumption and increase payload. Consequently, the light yet sturdy construction provided by titanium greatly enhances aircraft performance.

Titanium also boasts excellent corrosion resistance, which serves an important role, especially in manufacturing medical devices. Devices such as implants or surgical equipment need to withstand various conditions including exposure to body fluids, without degradation for patient safety. As such, titanium’s ability to resist corrosion effectively meets this requirement.

Moreover, the biocompatibility of titanium sets it apart, making it suitable for internal bodily applications like medical implants. The human body generally accepts titanium without causing adverse reactions. For instance, titanium has been widely used in orthopedic implants due to its compatibility. Thus, the factors of durability, light-weightiness, corrosion resistance, and biocompatibility combine to underline the significance of titanium CNC machining in both aerospace and medical industries.

Challenges Faced in Titanium CNC Machining

When it comes to titanium CNC machining, several challenges are encountered, including:

- Difficulty in machining: Titanium is known for its poor machinability, requiring specialized tools and techniques for effective CNC machining.

- Cost considerations: Titanium is an expensive material, leading to higher production costs for CNC machining processes.

- Tool wear: Titanium’s abrasive nature can cause increased tool wear, necessitating frequent tool changes and maintenance.

Overcoming these challenges requires expertise and advanced machining capabilities. Consider utilizing a Precision Machining Service to ensure high-quality results in titanium CNC machining.

Applications of Titanium CNC Machining in Aerospace Industry

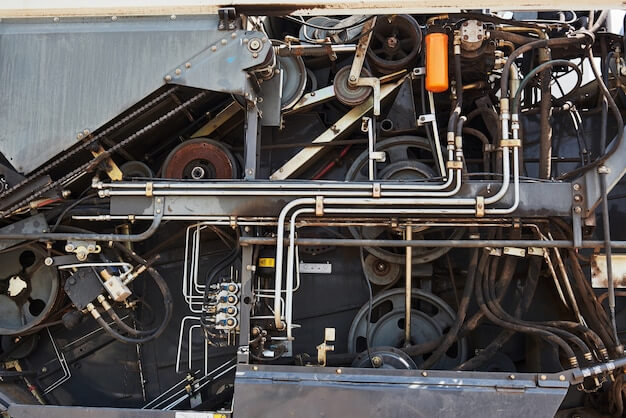

Titanium CNC machining offers multifaceted utilization within the aerospace industry, benefitting from titanium’s superior strength and lightness. Large-scale aircraft construction frequently employs this process; essential components such as engine parts, landing gear, ornamentation, hydraulic systems are fabricated using titanium.

- Aircraft Components: For instance, jet engines require durable, heat-resistant materials that can withstand extreme temperatures while maintaining a low weight quotient. As such, titanium becomes an ideal choice, as it is often used to manufacture high-pressure compressor blades and disks.

- Spacecraft Construction: A high-profile example of titanium use in spacecraft manufacturing is seen with NASA’s Mars Rover missions. These automated vehicles being sent to the red planet have several key titanium parts, including the chassis and protective shields, due to its corrosion resistance and toughness even at extremely low temperatures.

Applications of Titanium CNC Machining in Medical Industry

The medical industry has found significant applications for the precision and durability that titanium parts offer, thanks to CNC machining. One of these applications is for crafting intricate surgical instruments. Due to its advanced technology, CNC machines are employed to craft various surgical tools where precision and sterility are paramount, including scalpels, forceps, and retractors.

- Surgical Instruments: The complex geometry of certain surgical tools pose a challenge for many manufacturing processes; however, due to the high precision capabilities of CNC machining, even the most detailed instruments can be accurately crafted with tight tolerances.

Similarly, the ability of titanium to withstand extreme conditions makes it a desirable choice for creating orthopedic implants such as hip and knee replacements. These devices must sustain intense physical stress while being biocompatible, two areas where titanium certainly excels.

- Orthopedic Implants: Joint replacement surgeries require durable and long-lasting materials. As a result, titanium parts manufactured through CNC machining have become prevalent in producing joint replacement components like hip sockets and knee joints due to their robustness, light weight, and compatibility with human tissue.

Future Improvements & Predictions in Titanium CNC Machining

In titanium CNC machining, there are focused efforts on overcoming existing machining challenges and lowering production costs through technological advancements. For instance, various strategies such as the introduction of multi-tasking machines capable of performing multiple operations simultaneously, or the use of high-pressure cooling systems that enable efficient heat dissipation, are being explored to tackle the difficulties inherent to machining titanium. Both strategies not only increase productivity but also extend tool life, resulting in reduced operational costs.

Besides these, research and development activities are also concentrating on technological breakthroughs potentially beneficial for reducing production costs. One foreseeable advancement is the incorporation of machine learning algorithms into fabrication processes. With this approach, intelligent software could analyze vast amounts of machining data in real-time and thereby enable more precise control over machining parameters thereby optimizing productivity and minimizing waste. Additionally, the advent of hybrid additive-subtractive manufacturing technology presents another notable potential benefit; it allows for the direct 3D printing of complex parts with minimal wastage – thus saving on material and time costs.

- Multitasking Machines: Capable of performing multiple operations simultaneously increasing productivity and extending tool life.

- High-Pressure Cooling Systems: Enable efficient heat dissipation reducing stress on tools leading to longer lifespans and lower replacement costs.

- Machine Learning Algorithms: Allow real-time analysis and precise control over machining parameters enhancing efficiency and reducing waste material.

- Additive-Subtractive Manufacturing Technology: Allows direct 3D printing of complex components minimising material and time expenditure hence reducing production cost.

Related Posts

- The Functionality of Cantilever Snap Joints in CNC Machining(how does a cantilever snap joint work Rory)

The Functionality of Cantilever Snap Joints in CNC Machining The functions of cantilever clamp joints in CNC machining include several aspects: Positioning and Fixation: Cantilever clamp joints effectively position and…

- Understanding The Functionality of Cantilever Snap Joints( Linda)

A cantilever snap joint, also known as a snap fit, is a critical component regularly used in countless mechanical and electronic applications. This type of fastening device does not require…

- Online CNC Machining Services: How to Ensure Quality and Timeliness?

Introduction to Online CNC Machining Services: Ensuring Quality and Timeliness In the world of online services, Computer Numerical Control (CNC) machining stands out due to its precise, automated manufacturing process.…