Introduction to CNC Machining and the Challenges of Hardened Steels

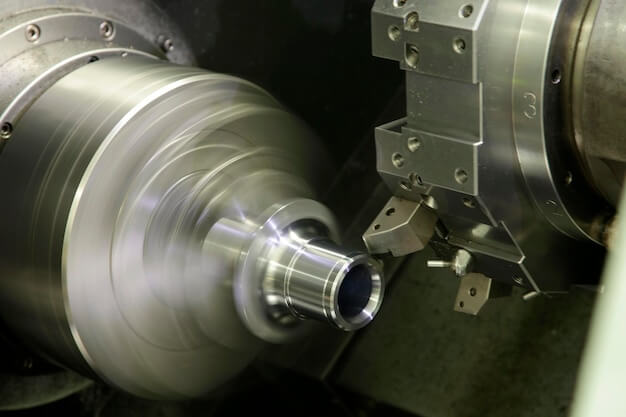

CNC machining is a crucial process in tool and die making, heavily relied upon for its versatility and precision-driven manufacturing capacity. To put it simply, Computer Numerical Control (CNC) utilises computer-programmed software to drive factory machinery, thereby ensuring detailed accuracy in end products.

The importance of this highly automated technology in shaping, cutting, drilling, and generally manipulating hardened steels – amongst other materials – contributes significantly to modern engineering and manufacturing sectors.

However, one key challenge that often arises involves the hardening of steels. This metallurgical method increases the hardness and strength of steel tools through heat treatment, but when handled with CNC machines, few complexities can be observed which include:

- Higher wear and tear of cutting tools due to friction between the hardened steel and the tool.

- Deterioration in product quality caused by excessive vibration or thermal deformation during the machining of hardened steel.

- Increased energy consumption and longer operation time due to the high toughness of hardened steel.

Understanding these challenges is vital for devising innovative solutions that will contribute towards more efficient, economically viable, and sustainable CNC machining methods in the tool and die-making industry.

Understanding the Challenges of Machining Hardened Steel

Hardened steel, owing to its exceptional hardness and robustness, plays a crucial role in manufacturing durable machining tools. The defining properties of hardened steel, including its high tensile strength and resistance to wear, make it an indispensable material in tool and die making. However, these desirable features bring along several complexities when it comes to processing or machining hardened steel.

The primary challenge arises because of an inverse relationship between the hardness of steel and its machinability, that is, as the hardness of the steel increases, its machinability decreases. This essentially means that material removal becomes more difficult, resulting in slower machining speeds and increased energy consumption during production processes.

- Machining hardened steel sharply accelerates wear and tear on machinery parts due to the abrasive nature of hard metals. It thus reduces lifespan and operational efficiency of the equipment, necessitating frequent maintenance and replacements, which can be costly.

- Furthermore, ensuring precise dimensional control while machining hardened steel also proves a daunting task. Due to the hardness of the metal, minor errors or fluctuations in the machining process could result in significant product deformities. Take, for instance, maintaining desired hole diameters when drilling through hardened steel – any slight deviation from the specified parameters may lead to oversized or undersized holes, impacting assembly fits and function.

Innovative Techniques and Existing Solutions to Challenges in CNC Machining Hardened Steel

When CNC machining hardened steel for tool and die making, innovative techniques and existing solutions play a crucial role in overcoming challenges. Utilizing advanced cutting tools with specific coatings, such as TiAlN or TiCN, can enhance the tool life and machining efficiency when working with hardened steel. Additionally, employing high-speed machining strategies and optimizing cutting parameters can further improve the process of machining hardened steels, ensuring precision and quality in tool and die manufacturing.

Exploring Further Possibilities and Future Implications

The continuous research and development in the field of machining processes offer ample opportunities for us to address existing challenges, specifically in CNC machining of hardened steels. For instance:

-

Experts are exploring novel cutting-edge technologies, like nanotechnology or laser technology, which can potentially lead to more efficient ways of tool and die making.

-

A significant part of this exploration lies in creating hardware improvements, such as resistance enhanced spindles or heat optimized drill bits which could bridge gaps in the present setup.

-

In terms of software enhancements, efforts are directed towards developing advanced algorithms with finer tuning capabilities leading to improved speed regulation, precise control over motion paths, and better compensation mechanisms.

These technological enhancements have paramount importance not only in automating the process but also ensuring a higher degree of precision with optimal use of resources. Moving forward, our industry should anticipate further advancements that align themselves with global standards & expectations. As we delve deeper into artificial intelligence (AI) and machine learning (ML), it is viable to foresee potential solutions created from these technologies designed to tackle prevalent issues.

Related Posts

- Exploring Bead Blasting in CNC Machining(torsion snap joint Uriah)

Bead blasting is an essential process within the broader umbrella of CNC (computer numerical control) Machining. Understanding its role and functions can provide a unique perspective on manufacturing and production,…

- Precision CNC Machining Services for Aerospace: Specializing in Aluminum

Introduction to Precision CNC Machining Services in Aerospace Precision CNC (Computer Numerical Control) machining is a modern manufacturing technique that uses computer-controlled machine tools to create intricate parts with extreme…

- Ceramics in CNC Machining: Are They as Effective as Metals?

Introduction to CNC Machining and Ceramics CNC machining, or Computer Numerical Control machining involves the use of computers to control machine tools in the manufacturing process. This highly efficient method…