In the realm of precision engineering, achieving impeccable surface quality and dimensional accuracy is paramount. Bead blasting technology has emerged as a versatile solution for refining aluminum components, offering meticulous control over surface finishes and intricate details.

Understanding Bead Blasting Process for Aluminum

Bead blasting, also known as abrasive blasting, involves propelling fine glass beads at high velocity onto aluminum surfaces. This abrasive action efficiently removes surface imperfections, burrs, and contaminants, resulting in a uniform and refined finish.

Benefits of Bead Blasting for Aluminum Components

- Enhanced Surface Finish: Bead blasting imparts a smooth and uniform texture to aluminum components, enhancing their visual appeal and tactile feel.

- Deburring and Deflashing: The abrasive action of glass beads effectively removes burrs, sharp edges, and excess material from machined aluminum parts, ensuring precise dimensions and functionality.

- Surface Preparation for Coating: Bead blasting creates an optimal surface profile for subsequent coating applications, such as anodizing or powder coating, promoting adhesion and durability.

- Selective Material Removal: Bead blasting allows for precise material removal, enabling engineers to achieve intricate designs and features on aluminum components.

Applications of Bead Blasting in Precision Engineering

- Aerospace Components: Bead blasting is extensively used in aerospace engineering to prepare aluminum components for critical applications such as aircraft fuselages, engine parts, and structural elements. The process ensures uniform surface finishes and removes any surface defects that could compromise structural integrity or aerodynamic performance.

- Medical Devices: In the medical device industry, precision is paramount. Bead blasting is employed to refine aluminum components used in medical implants, surgical instruments, and diagnostic equipment. The process not only enhances the aesthetic appeal of the devices but also ensures biocompatibility and cleanliness, critical factors in medical applications.

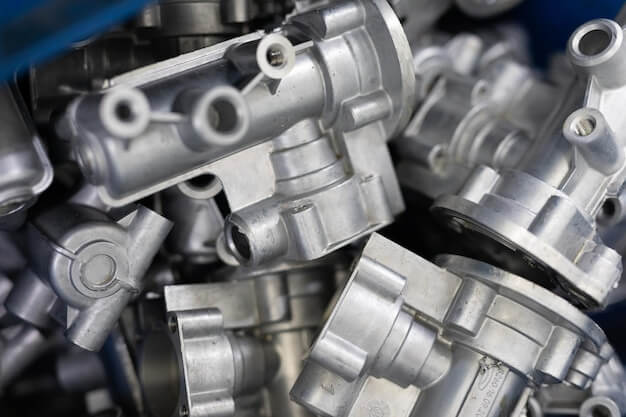

- Automotive Parts: Bead blasting plays a crucial role in automotive engineering, particularly in the production of aluminum engine blocks, transmission housings, and chassis components. By removing surface imperfections and preparing the surface for coatings, bead blasting improves the durability and performance of automotive parts, contributing to the overall reliability of vehicles.

- Electronic Enclosures: Precision engineering in electronics demands flawless surface finishes and exacting tolerances. Bead blasting is employed to refine aluminum enclosures for electronic devices such as smartphones, laptops, and audio equipment. The process creates a uniform surface texture and removes any surface contaminants, ensuring optimal performance and longevity of electronic components.

Conclusion: Advancing Precision with Bead Blasting

In conclusion, bead blasting technology offers a precise and versatile solution for refining aluminum components in precision engineering applications. By leveraging bead blasting, engineers can achieve impeccable surface finishes, precise dimensions, and enhanced functionality in a wide range of industries, from aerospace and medical to automotive and electronics. As precision engineering continues to evolve, bead blasting will remain a cornerstone technique for elevating the quality and performance of aluminum components.

Related Posts

- Precision CNC Machining for the Aerospace Defense Industry

Precision CNC Machining in the Aerospace Defense Industry In modern manufacturing sectors, precision Computer Numerical Control (CNC) machining plays a critical role. It is an automated process that uses pre-programmed…

- Bead Blasting Mastery: Achieving Consistent Quality and Precision

1. Introduction: The Art and Science of Bead Blasting Mastery In this introductory section, we delve into the world of bead blasting, emphasizing its role in achieving consistent quality and…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…