CNC Machining and Aluminum Grades

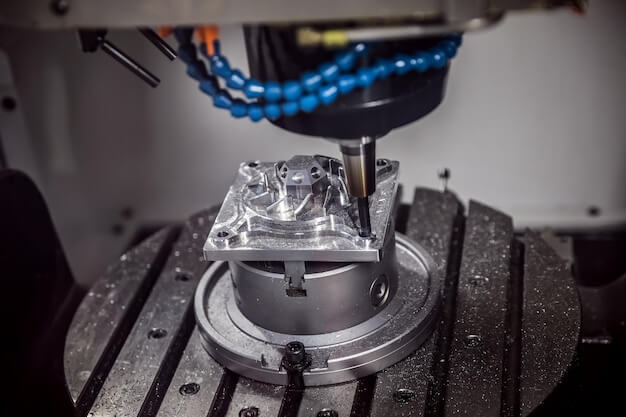

Computer Numerical Control (CNC) machining is a widely adopted manufacturing procedure employed to create complex parts with high precision. This advanced technology finds its significant application spectrum across automotive, aerospace, renewable energy sectors, among others. When it comes to materials involved in CNC machining, aluminum leads the pack due to its several quintessential characteristics including lightness and outstanding corrosion resistance.

- Aerospace-grade aluminum (commonly 7075 or 2024 alloys), for instance, has enhanced strength thus preferred for building aircraft structures where weight reduction can contribute to better fuel efficiency.

- Commercial-grade aluminium predominantly used in applications that do not necessitate a similar level of performance as required by the aerospace industry.

This dichotomy significantly affects the balance between precision and cost during CNC machining operations given industrial-quality aluminum offers reasonable accuracy at considerably lower costs.

Understanding Precision in CNC Machining

Precision in Computer Numerical Control (CNC) machining is a fundamental aspect that determines the quality of final products. This manufacturing process uses a pre-set computer software to dictate the movements of factory tools and machinery, therefore the precision refers to how accurately these machines can follow the programmed instructions. In aerospace and commercial applications, this level of accuracy is crucial as it directly impacts the function, safety, and reliability of the end product.

A practical example highlighting its importance would be in the production of aircraft parts. High-precision CNC machined components ensure structural integrity, which is critical for an airplane’s safe flight. In contrast, even the tiniest fault due to lack of precision could lead to catastrophic failures. Similarly, in commercial sectors, such as automotive or consumer electronics, high precision equates to better performance and longer lifespan of the products.

- The role of precision: Precision in CNC machining ensures these machines can accurately translate digital instructions into physical movements, producing high-quality output.

- Importance in aerospace: Being precise contributes to fulfilling stringent requirements related to safety, reliability and structural integrity in aerospace industry.

- Relevance in commercial applications: Precision too plays a part in determining the performance standards and durability of commercial products like vehicles or gadgets.

Understanding Costs in CNC Machining

When it comes to CNC machining, understanding the costs involved is crucial for making informed decisions. Here is a step-by-step description of the factors that influence costs in CNC machining:

1. Material Selection:

- The choice of material for CNC machining can significantly impact costs.

- High-performance materials like aerospace-grade aluminum are generally more expensive than commercial-grade aluminum.

- Commercial-grade aluminum offers a cost-effective option for many applications, while aerospace-grade aluminum provides enhanced properties but at a higher cost.

2. Production Time:

- The time required for CNC machining affects costs.

- Complex designs or parts with tight tolerances may require longer machining times, increasing production costs.

- Efficient programming and optimization can help reduce production time and lower costs.

3. Part Complexity:

- The complexity of the part being machined impacts costs.

- Intricate geometries and tight tolerances may require specialized tools, additional setup time, and skilled operators, increasing costs.

- Simplifying the design and reducing complexity can help lower costs by reducing machining time and the need for advanced machinery.

4. Post-Processing Treatments:

- Post-processing treatments, such as surface finishes or coatings, can add to the overall cost of CNC machining.

- Choosing simpler surface finishes, like As-Machined, for highly machinable materials can help reduce costs.

- Consistent finishing criteria across components can also contribute to cost reduction.

By considering these factors, manufacturers can optimize costs in CNC machining projects. To explore CNC machining services that offer expertise in aerospace-grade and commercial-grade aluminum machining, you can visit our online CNC service.

Trade-offs Between Precision & Cost in CNC Machining

The correlation between precision and cost in Computer Numerical Control (CNC) machining, especially when using different grades of aluminum for aerospace applications is an intricate balance. The grade of aluminum used can significantly impact both the project’s final expense and its precise attributes. Aerospace-grade aluminum is highly priced because it provides exceptional precision, but on the other hand, commercial-grade aluminum is more budget-friendly yet may offer less precision.

- Aerospace-grade Aluminum: Offers higher corrosion resistance, improved strength at high temperatures, and enhanced machinability resulting in a higher level of detail and precision on the end product. However, this comes with increased costs owing to the premium quality of this metal and the processing equality required, which may not be feasible for all projects due to budget constraints.

- Commercial-grade Aluminum: On the contrary, commercial-grade aluminum might lack the same levels of detailing and precision that aerospace-grade offers, nevertheless still ensuring good durability and workability at a significantly lower price point, making it an attractive choice for projects with tighter budgets or less demanding precision requirements.

In hypothetical scenarios, if a project requires a very high degree of precision, like parts for a spacecraft, opting for aerospace-grade aluminum would be optimal despite its elevated cost. Conversely, for mass-produced items where some slight variances are acceptable, commercial-grade aluminum can provide decent precision at reduced costs, demonstrating the trade-offs between precision and cost related to the choice of aluminum grade.

Benefits and Limitations of Aerospace-Grade Aluminum in CNC Machining

Aerospace-grade aluminum presents several advantages over commercial-grade aluminum for use in CNC machining. Notably, it offers superior strength, precision tolerances, increased durability, better corrosion resistance, and improved thermal heat management; thus making it an ideal material choice for high-demand applications such as aerospace components. For example, the impressive tensile strength of aerospace-grade aluminum ensures that machined parts can withstand extraordinary force without deforming or breaking.

- Strength: It’s stronger than commercial-grade aluminum. The higher strength makes this material suitable for highly stressed parts with less thickness, saving on both weight and fuel costs.

- Tolerance: Precision tolerance is another major benefit, reducing any deviations during component assembly and ensuring smooth operation.

- Durability: Increased durability implies longer product life cycles and less frequent replacements, leading to cost savings in the long term.

However, these benefits come at a price. First, aerospace-grade aluminum is significantly more expensive than its commercial counterpart due to the complexity involved in achieving such enhanced properties. Additionally, machining aerospace-grade material necessitates the use of specialized machinery, tooling, and programming to maintain stringent quality and accuracy standards, contributing to increased capital and operational costs. High-end machines and skilled technicians are required, further driving up expenses.

Benefits and Limitations of Commercial-Grade Aluminum

In the realm of CNC machining, commercial-grade aluminum offers several notable benefits. Primarily lauded for its affordability, this type of aluminum ensures cost-effectiveness in production processes. As a readily available material, it further enhances operational efficiency which can translate to higher productivity rates. Moreover, its versatility lends itself well to varied applications, making it an adaptable choice across different machinery setups.

- Affordability: It is less expensive than aerospace-grade aluminum thus reducing production costs.

- Wider Availability: Due to its common use in multiple industries, it is widely accessible reducing procurement challenges.

- Versatility: Its adaptability allows it to be used in diverse machine configurations, enhancing application scope.

Conversely, there are certain limitations with using commercial-grade aluminum. In comparison to aerospace-grade counterparts, it may deliver lower precision —a critical factor in CNC machining operations— thereby sometimes compromising product quality. Furthermore, its performance under harsh conditions might not measure up, accordingly limiting its utility in environments that demand high resilience or exceptional durability.

- Lower Precision: Compared to aerospace-grade options, it tends to provide lesser precision, potentially affecting final product specifications.

- Decreased Performance Under Harsh Conditions: They’re typically less robust when exposed to extreme pressure, temperature variations, or corrosive forces.

Making the Right Choice: Aerospace vs Commercial Grade Aluminum – Evaluating Application Needs

Deciding between aerospace-grade and commercial-grade aluminum requires a careful evaluation of your project’s demands. For applications where high-precision is critical, such as in aerospace components or medical equipment, aerospace-grade aluminum is often the preferred choice despite its higher cost. The material’s superior strength, corrosion resistance, and dimensional stability can make it imperative for meeting stringent tolerances.

In contrast, projects that allow for minor inaccuracies might not necessitate this added investment. Commercial-grade aluminum may suffice for these types of situations; it offers reasonable structural integrity at a less expensive upfront cost. But remember, the potential costs associated with component failure must be accounted for when choosing the right material.

- Aerospace-grade aluminum: High precision but expensive.

- Commercial-grade aluminum: Lower cost, allows minor inaccuracies.

Cost-Benefit Analysis: When Investing in More Expensive Materials Pays Off

A strategic cost-benefit analysis genuinely manifests the value in using more expensive materials like aerospace-grade aluminum. These costly materials usually have enhanced properties making them ideal for complex technical applications requiring high accuracy levels. While initial costs might seem prohibitive, their durability, performance under extreme conditions, reduced maintenance requirements, and longer life cycles validate the price point.

Related Posts

- The Advantages of Using LSR (Liquid Silicone Rubber) in CNC Prototyping and Production?

Introduction to LSR in CNC Prototyping and Production The utilization of Liquid Silicone Rubber (LSR) in CNC prototyping and production has been growing exponentially due to its numerous advantages. For…

- Choosing the Right CNC Machining Shop: Factors to Consider

Choosing the Right CNC Machining Shop: An Introduction In today's advanced manufacturing environment, Computer Numerical Control (CNC) machining plays a significant role. CNC machining is a process utilized in the…

- Aluminum CNC Machining Part Production for Custom Solutions

Introduction to Aluminum CNC Machining Part Production CNC (Computer Numerical Control) machining is a subtractive manufacturing technology whereby computer software directs the movement of factory machinery and tools, ensuring precision…