When it comes to CNC machining, choosing the right tools can make a world of difference. The right tool selection not only improves efficiency but also ensures the safety and longevity of your equipment. Let’s dive into the essential considerations for selecting and applying tools in CNC machining.

The Importance of Tool Selection

Tool selection in CNC machining isn’t just about picking a cutter that fits. It involves a comprehensive understanding of the machining process, the material being machined, and the specific requirements of the part being produced.

Here are the two main criteria for selecting tools:

- Efficiency: The tool should perform the task quickly and effectively.

- Safety: The tool must operate safely under the given conditions.

Ignoring these aspects can lead to longer machining times, increased wear and tear on tools, and even potential accidents.

The Basics: Types of Tools and Holders

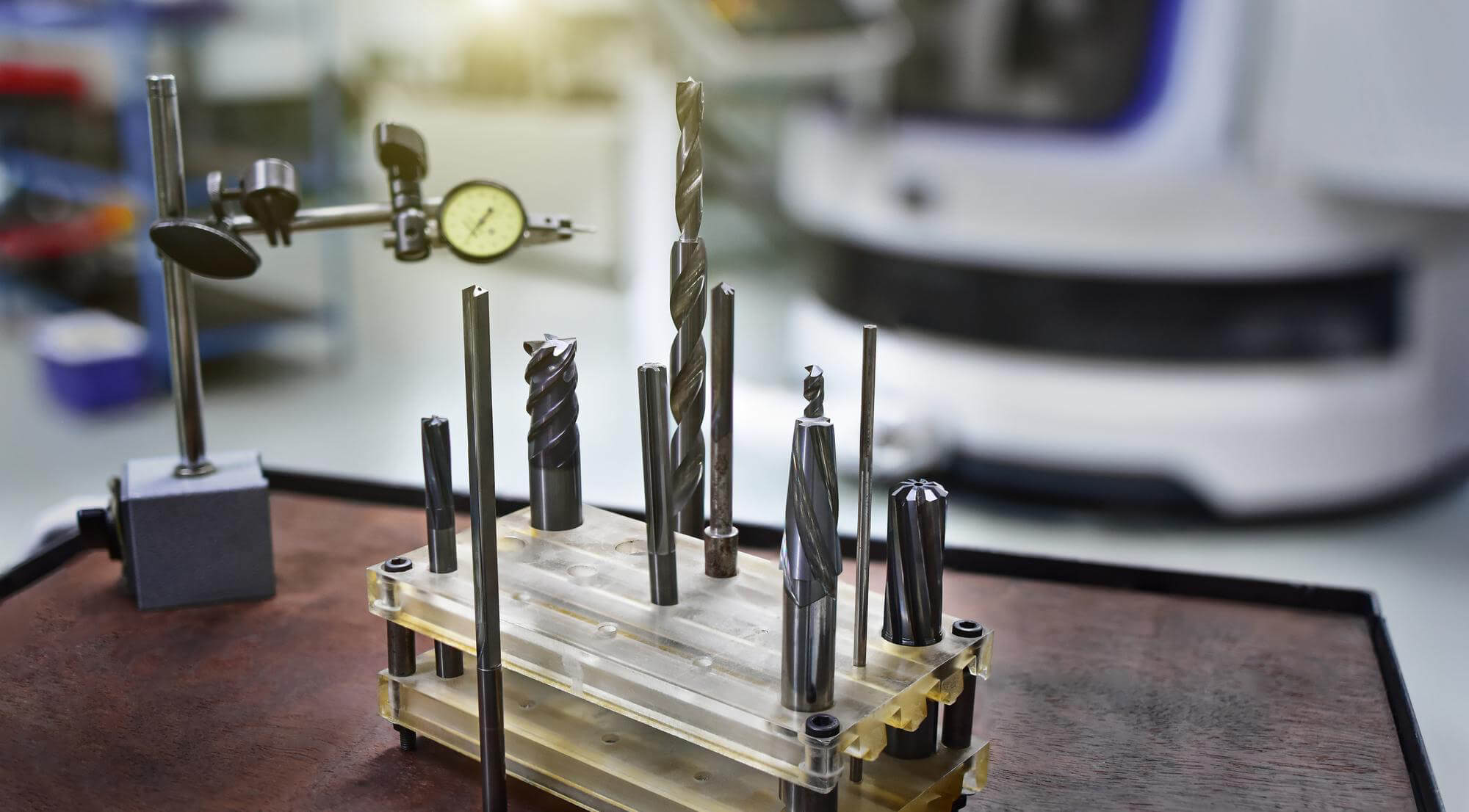

CNC machining involves various tools and holders, including vises, fixtures, chucks, auxiliary tables, steady rests, tailstocks, index tables, clamps, collets, and many other holding and auxiliary devices. The cutting tools themselves come in many shapes and sizes, each designed for specific operations.

Cutting Tools: These are the heart of the CNC machining process. The selection of cutting tools includes considerations for the type of material being machined, the desired surface finish, and the geometrical complexity of the part. Typical tools include end mills, drills, reamers, taps, and turning tools.

Tool Holders: These are used to secure the cutting tools in the CNC machine. Proper selection of tool holders is crucial for maintaining precision and reducing vibration during machining.

Maximizing Efficiency and Safety

Many CNC programmers focus on keeping their current tools running continuously, often overlooking the fact that a new, more suitable tool could complete the job faster and more economically. A thorough understanding of cutting tool applications is vital. This knowledge extends beyond the tools themselves to include the accessories and attachments that enhance their performance.

Here’s a look at how to optimize tool selection:

- Balancing Tool Lengths: On a CNC lathe, it’s important to distribute short and long tools (like turning tools and boring bars) evenly to prevent interference during cutting or tool changes.

- Sequencing Tools: The order in which tools are called is especially important on machines without bi-directional tool retrieval. Even in random-type tool changers, considering tool diameter and weight can be critical.

Tool Arrangement in CNC Programming

Assigning specific tool positions in CNC lathes ensures balanced distribution and prevents interference. It’s essential to back up tool offset numbers and other program inputs in a setup sheet. This documentation should include basic information related to the selected tools, such as length, diameter, number of flutes, tool and offset numbers, and the selected speeds and feeds.

Here’s an example of how a tool setup sheet might look:

| Tool No. | Operation | Length (mm) | Diameter (mm) | Flutes | Offset No. | Speed (RPM) | Feed Rate (mm/min) |

|---|---|---|---|---|---|---|---|

| T01 | End Mill | 100 | 10 | 4 | G54 | 1200 | 200 |

| T02 | Drill | 80 | 8 | 2 | G55 | 1500 | 300 |

| T03 | Tap | 75 | 6 | – | G56 | 800 | 100 |

The Role of Tool Suppliers

Tool suppliers are a valuable resource for CNC programmers. Representatives from tooling companies often provide crucial assistance in selecting the right tools and optimizing their applications. They can offer insights into the latest advancements in tooling technology and best practices for their use.

Practical Considerations

When it comes to actual tool selection and application, consider the following:

- Material Compatibility: The tool material must be compatible with the workpiece material. For example, carbide tools are excellent for high-speed machining of hard materials, while high-speed steel (HSS) is suitable for softer materials.

- Tool Geometry: The shape and angle of the cutting tool should match the operation requirements. Proper tool geometry reduces cutting forces and improves surface finish.

- Coolant Use: Appropriate coolant can extend tool life and improve machining quality. The choice of coolant depends on the material and the cutting conditions.

Example: Machining a Complex Part

Let’s consider the example of machining a complex part involving multiple operations:

- Roughing: Start with a robust end mill to remove large amounts of material quickly.

- Drilling: Switch to a drill bit designed for the specific material to create precise holes.

- Tapping: Use a tap to add threads to the drilled holes.

- Finishing: Employ a finishing tool to achieve the desired surface finish and final dimensions.

By carefully selecting tools for each stage of the process, you can ensure efficient and high-quality machining.

Choosing the right tools in CNC machining is a blend of science and art. It requires a deep understanding of the machining process, the materials involved, and the specific needs of each job. By focusing on efficiency and safety, and leveraging the expertise of tool suppliers, CNC programmers can optimize their tool selections and achieve outstanding results. Whether you’re machining simple parts or complex components, the right tools make all the difference.

Related Posts

- The Engineer's Guide to Reducing CNC Machining Time: Material and Tool Selection Strategies

Importance of Reducing CNC Machining Time In the expansive world of industrial manufacturing, Computer Numerical Control (CNC) machining holds a dominant place due to its effectiveness in reducing errors, enhancing…

- Tool compensation in CNC machining, our quest for precision in CNC machining

Introduction to CNC Machining and Precision CNC (Computer Numerical Control) machining stands at the forefront of modern manufacturing, utilizing computerized controls to operate complex machinery with remarkable accuracy. This process…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Analysis of machining process for CNC machine tool parts, formulation of machining plans, selection of fixtures and cutting tools

CNC Lathe Processing Based on Material, Contour Shape, and Machining Precision of Workpiece: Selection of Suitable Machine Tools, Development of Processing Plan, and Determination of Processing Sequence, Tools, Fixtures, and…

- Optimizing Tool Paths: Advanced Techniques for Efficient CNC Titanium Machining in China

Introduction to CNC Titanium Machining in China In the dynamic landscape of global manufacturing, China stands out, especially in CNC (Computer Numerical Control) machining. Titanium, prized for its strength and…

- The Future of CNC Machining in Sustainable Manufacturing

The Future of CNC Machining in Sustainable Manufacturing CNC (Computer Numerically Controlled) machining and sustainable manufacturing are two significant areas with increasing potential in the industrial sector. CNC machining is…