Introduction: CNC Machining in Medical Device Industry

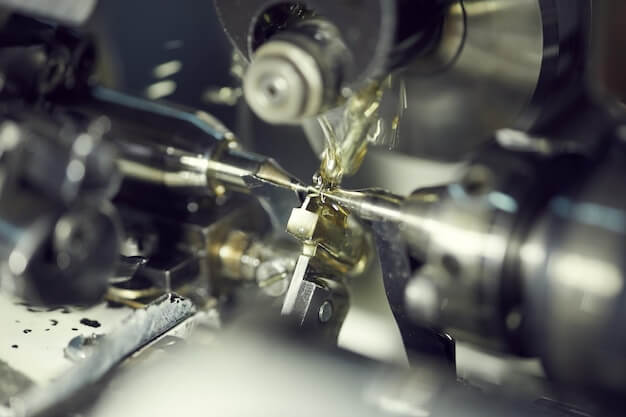

CNC (Computer Numerical Control) machining is a pivotal process in the production of medical devices. This technique employs computerized controls to operate and manipulate machine tools, ensuring high precision, accuracy, and consistency in manufacturing processes. In an industry where every micron matters, such as the creation and development of life-saving medical equipment like surgical instruments or implants, the role played by CNC machining becomes crucial.

- This technology provides the ability to produce complex shapes that would be almost impossible to achieve with manual machining.

- CNC machining also excels in reproducing items, guaranteeing each piece produced is identical to the specification – this repeatability aspect is essential in the medical device sector.

- Lastly, automated machining reduces human error and increases manufacturing speed, making it a cost-effective solution for large-scale productions.

As advancements continue to transform the field of medicine, CNC machining remains integral to these revolutionary changes, shaping the future landscape of the medical device industry.

Historical Overview of Traditional Use of CNC Machining in Medical Device Manufacturing

In the past, the manufacturing of medical devices heavily relied on Computer Numerical Control (CNC) machining. This technology hinges upon precise instructions encoded using a software program to control how the machine tools function. In particular, CNC machining was utilized extensively for its accuracy and repeatable capabilities – absolutely critical features when creating intricate components that make up medical instruments or devices.

- Implants: For instance, CNC machining has been traditionally used to construct orthopedic implants like knee or hip replacements. Its high precision ensured these implants exactly match a patient’s anatomy.

- Surgical Instruments: Additionally, surgical tools such as drill guides benefited from this advanced technology by ensuring functionality and exact sizing.

- Diagnostic equipment: Complex diagnostic tools also required the detailed precision provided by CNC machining to achieve reliable and consistent results.

Therefore, recognizing the vital role that CNC machining played historically only underscores its potential moving forward in revolutionizing the future of medical device manufacturing.

The Need for Revolutionizing CNC Machining

The current landscape of CNC (Computer Numerical Control) machining faces inherent restrictions that inhibit its perfect application within the medical device landscape. Traditional CNC machines, while lauded for their precision and consistency, are often slowed down by laborious setup times, coupled with a limited ability to adapt to design changes swiftly. A prime example is in the manufacturing process of orthopaedic implants where frequent adjustments are required alongside comprehensive inspections, demanding more flexibility than what current CNC technology can offer.

Furthermore, evolving requirements within the healthcare sector necessitate this spotlight on revamping CNC practices. With medical devices becoming more intricate and personalized care increasingly central to treatment plans, there’s an escalating need for adaptable production techniques. Consequently, advanced prototyping abilities, rapid responses to engineers’ demands, and increased automation levels have transformed from desirable additional amenities into essential components within contemporary medical device manufacturing. These urgent demands mandate swift revolutions in CNC methodologies to foster improved efficiency while diminishing error rates.

Future Needs and Opportunities for CNC Machining in the Medical Device Sector

The imminent challenges in the medical device sector, including rising demand for precision parts, complex geometries, and compact devices, necessitate sophisticated manufacturing technologies. CNC machining is poised to offer unprecedented solutions given its capability to attain unparalleled accuracy, flexibility and scalability. Consider a hypothetical scenario where a groundbreaking neurological device that requires intricate components on a microscopic level needs developing. Traditional methods would struggle with production due to scale and complexity. However, advances in CNC technology like five-axis machines or micro-machining can efficiently produce these complex pieces, hence overcoming said challenge.

- CNC machinings’ capability for precision crafting of medical components rectifies quality control concerns associated with manual machining;

- Faster production speeds meet increasing consumer demand;

- Its adaptability accommodates for evolving designs as scientific understanding progresses;

- Lastly, scalability allows cost-effective mass-production whilst maintaining high standards of consistency, crucial in medical contexts where slight deviations may result in catastrophic implications.< /li>

In essence, the revolution of CNC machining presents golden opportunities to tackle upcoming obstacles in the medical device sector effectively, while also paving new paths for invention and innovation.

Technological Innovations Influencing CNC Machining Industry:

- Step 1: The introduction of advanced software and hardware has significantly enhanced the precision and production capabilities of CNC machining in the medical device industry.

- Step 2: CNC machining has evolved over the years with the incorporation of more advanced technology, allowing for the production of high-quality and high-precision medical products within a short period of time.

- Step 3: The future of CNC machining is expected to play a significant role in the medical industry, offering economical solutions and optimized production costs for complex medical components and assemblies.

Examining the Impacts of Revolutionary CNC Machining on Medical Devices Manufacturing

Advanced Computer Numerical Control (CNC) machining provides promising impacts on medical device production, owing to its potential for enhancing quality, affordability, and speed. The precision granted by advanced CNC machining methods surges quality assurance in device production, minimizing defects that could compromise patient safety. For instance, intricate dental implants can be constructed with exact measurements matching each individual, preventing discomfort and complications with singularly-fabricated devices.

To illustrate, a manufacturing company utilizes high-speed five-axis CNC mills to expedite the creation of batches of complex orthopedic medical implements. This illustrates how faster production timelines can be achieved without detrimentally impacting quality or costs, thus promoting affordability and accessibility. These advancements provide direct benefits to end-users through improved clinical outcomes facilitated by consistent excellence in product design, user-friendly features, and shortened lead times. Apart from this, healthcare providers stand to gain economically as quicker turnarounds allow for increased patient volume while maintaining high-standard care.

- Predicted impact: Enhanced Quality – With advanced CNC machining methods, deviations are minimized thereby increasing accuracy and consistency.

- Affordability – Automating device production efficiently reduces labor costs consequently making it more affordable for both manufacturers and end-users.

- Speed – High-speed mills accelerate production pace, leading to faster delivery times while ensuring products still meet stringent medical standards.

Challenges and Obstacles in Implementing Newer CNC Technologies

The integration of modern CNC technologies into the production of medical devices presents several challenges, primarily related to cost, complexity, and skill requirements. The initial investment for advanced CNC machines can be notably high due to their sophisticated features. Furthermore, operating these machines requires specialized skills and training.

- Cost: State-of-the-art CNC machines tend to have a higher price tag, making them inaccessible to smaller manufacturers.

- Complexity: Newer systems demand an understanding of intricate programming languages which could potentially slow down operation time during the transition period.

- Skill Requirements: There is a necessity for employees with technical expertise who can efficiently work with complex machinery and interpret detailed data. Lack of such skilled staffs might pose a significant challenge.

Possible solutions include utilizing government grants or subsidies to offset costs, offering extensive training programs to upgrade employee skills, and developing simpler user interfaces or automated software to streamline operations. Despite the hurdles involved in implementing new CNC technologies, innovative strategies can help overcome these obstacles.

Conclusion

In conclusion, the CNC machining revolution has undeniable potential for bolstering futurist medical device manufacturing. By adopting the innovative features of this technology such as enhanced precision, swift production speed, and affordability, we can potentially disrupt conventional patterns in the medical field. Given the high-stakes nature of healthcare, this level of accuracy and reliability could translate into lifesaving improvements for patients worldwide.

Embracing change isn’t just crucial; it’s inevitable. The future of medical devices lies not only in technological advancement but also in our willingness to continually embrace and adapt these changes for better outcomes. As stakeholders investing in a healthier world, we must focus on proactive strategies like integrating advancements like CNC machining that hold potential to broaden horizons both technologically and economically.

- Precision: Offering impeccable accurateness and attention to detail.

- Speed: Promising faster turnarounds due to automated processes.

- Affordability: Minimising costs with bulk production feasibility.

The dynamics are shifting towards an era wherein foresightedness coupled with advanced manufacturing strategies will propel growth trajectories. Let us remember that being open-minded about technological evolution is a significant step towards achieving unprecedented success in any industry, including healthcare. Hence, let us continue to strive for industrial excellence by harnessing the prowess of revolutionary technologies like CNC machining.

Related Posts

- The Art of Bead Blasting in CNC Machining(chamfers Drew)

Bead blasting signifies an integral part of the manufacturing industry, more so concerning computer numerical control (CNC) machining processes. This process offers invaluable benefits including the enhancement of product quality,…

- CNC Machining and the Quest for Lightweight Materials in the Aerospace Industry

Introduction to CNC Machining CNC Machining, standing for Computer Numerical Control Machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process…

- Exploring Bead Blasting in CNC Machining(chamfers Erin)

For anyone looking to achieve a smooth surface finish on their CNC machined parts, bead blasting is an indispensable technique. Bead blasting describes a process where small round beads are…