Bead blasting is a critical procedure inside an overarching process known as Computer Numerical Control (CNC) machining. Known for its precise and accurate nature, bead blasting helps remove surface deposits by applying fine glass beads at high pressure without damaging the surface.

Understanding CNC Machining

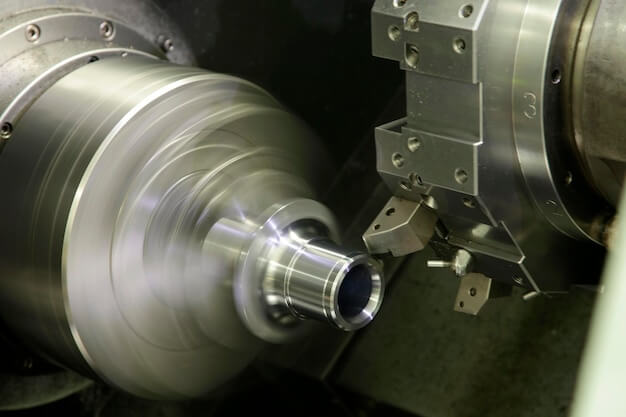

Before diving deep into bead blasting, let’s get a broader understanding of CNC machining. CNC machining refers to a subtractive manufacturing process where software directed systems drive complex machine parts production using pre-programmed computer software. The distinct advantage here lies in the accuracy with which intricate 3-dimensional cutting tasks can be accomplished effectively.

One such complementary technique within this realm is bead blasting that not only improves the aesthetic appearance of machined products but also enhances their operational functionality.

The Dynamics of Bead Blasting

An integral part of finishing operations in CNC machining, bead blasting utilizes air pressure to blast small glass beads at a surface to clean and fortify it. While choosing bead size directs how aggressive or gentle the process will be, adjusting nozzle speed and distance manages the overall effect on the workpiece surface.

For instance, bigger beads would etch deeper profiles, ideal for large heavy-duty components. Conversely, smaller beads are favorable for cleaning lighter stains and cosmetic finishes. This versatility underscores why bead blasting remains crucial to businesses spanning automotive, aerospace, medical devices industries, and more.

The Production Process

Here’s how bead blasting integrates within the CNC machining cycle:

1. CNC Programming – Every operation begins after creating a CAD model of the component; next, CAM software converts these models into CNC programs.

2. Setting up – Technicians prepare the CNC machine for production in terms of material selection, tool alignment, and securing holding fixtures.

3. Creation of Base Part – Directed by sophisticated computer programming, lathes, mills, grinders systematically carve the intended shape from a solid metal block.

4. Bead Blasting – The machined part undergoes bead blasting to remove any surface deposits and create required finishing.

5. Inspection & Testing – Trained engineers inspect the final component in line with industry specific quality standards.

Apart from enhancing aesthetics, bead blasting amplifies operational performance by several notches. It creates a uniform, non-directional finish which allows paint and other coatings to adhere better. It also deburrs parts perfectly, removing sharp edges that may cause harm. Moreover, it improves corrosion resistance offering long-term durability against wear and tear.

To Conclude

With technological advancements paving the way for more automated production processes like CNC Machining, bead blasting plays an influential role in polishing and purifying mechanical components. This potent combination of accuracy and finesse evidently demonstrates why manufacturers widely endorse bead blasting as the preferred method for product enhancement within the machining sector.

Ultimately, amidst increasing consumer expectations of flawless finishes and perfect fit, bead blasting continues to add significant value to CNC machining operations worldwide. Hence, knowledgeable understanding and skilled implementation of bead blasting can generate tremendous flexibility and boost overall competitiveness in the market.

Related Posts

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…