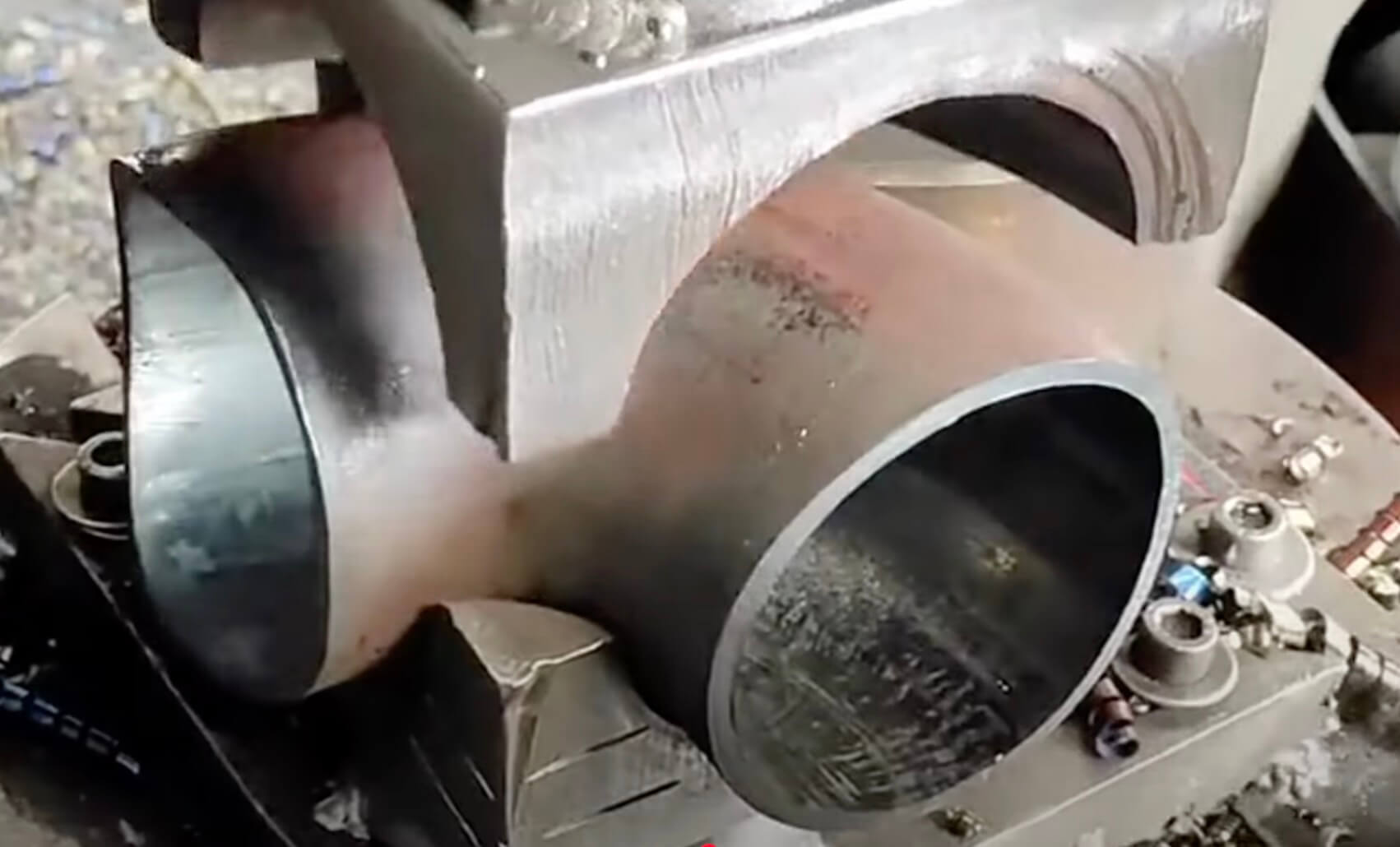

5-axis CNC machining is a highly advanced and precise manufacturing process used to create complex molds with undercut features.

What is Five-Axis Machining?

Five-axis machining refers to a CNC machine’s ability to move a tool or a part across five different axes simultaneously. These machines can move along the X, Y, and Z linear axes, and also rotate on the A and B axes, allowing for greater flexibility and precision.

What is Undercut Machining?

Undercut machining involves creating features in a mold that are not directly accessible from the direction of the tool path. These are areas where part geometry goes beyond a straight vertical or horizontal cut, often requiring the tool to reach around or beneath a feature.