CNC machining is a manufacturing process that involves the use of various cutting tools to remove material from a workpiece to create a desired shape or surface finish. Machining can be performed using various tools, including lathes, milling machines, drills, and grinders. The process involves cutting, drilling, shaping, and finishing the workpiece using specialized tools to create a precise and accurate part or component.

Machining can be performed on a variety of materials, including metal, plastic, wood, and composites. The process is used in a wide range of industries, including aerospace, automotive, medical, and electronics, among others. Machining can be performed using traditional manual machines or advanced computer-controlled CNC machines.

Machining typically involves a number of steps, including:

- Design – The design of the part or component is created using CAD (Computer-Aided Design) software.

- Tool selection – The appropriate cutting tool is selected based on the material and desired outcome.

- Set up – The workpiece is mounted onto the machine and aligned for the machining process.

- Machining – The cutting tool is used to remove material from the workpiece to create the desired shape or surface finish.

- Inspection – The finished part or component is inspected to ensure it meets the desired specifications.

- Finishing – Any necessary finishing operations, such as polishing or coating, are performed to complete the part or component.

Machining is an important process in manufacturing, allowing for the production of precise and accurate parts and components used in a wide range of products and industries.

1.Milling

Milling is a machining process used in CNC (Computer Numerical Control) machines that involves the removal of material from a workpiece using rotary cutters. In milling, a cutting tool rotates around its axis, while the workpiece is held stationary on a table or held in a fixture that can move in different directions. The cutting tool removes material from the workpiece in the form of chips, creating a desired shape or feature.

There are different types of milling operations that can be performed, depending on the desired outcome. Some of the most common milling operations include:

- Face milling – In face milling, the cutting tool is positioned perpendicular to the workpiece and removes material from the surface of the workpiece.

- End milling – In end milling, the cutting tool is positioned parallel to the workpiece and removes material from the end of the workpiece.

- Slot milling – In slot milling, the cutting tool creates slots or grooves in the workpiece.

- Profile milling – In profile milling, the cutting tool creates a complex shape or profile in the workpiece.

- Plunge milling – In plunge milling, the cutting tool is plunged into the workpiece to create a hole or cavity.

- Pocket milling – In pocket milling, the cutting tool creates a cavity or pocket in the workpiece.

CNC milling machines use computer programs to control the movement of the cutting tool and the workpiece, allowing for precise and repeatable machining operations. The operator enters the desired dimensions and shape into a computer program, which then generates the tool path and controls the movement of the cutting tool.

For example, let’s say you want to create a bracket for a machine using CNC milling. You would first create a CAD (Computer-Aided Design) drawing of the bracket, including all the necessary dimensions and features. Then you would input this design into the CNC milling machine, which would generate the tool path and control the movement of the cutting tool.

The machine would then use the cutting tool to remove material from the workpiece, following the programmed tool path. Once the milling operation is complete, the bracket would be removed from the machine and any finishing operations, such as sanding or painting, would be performed.

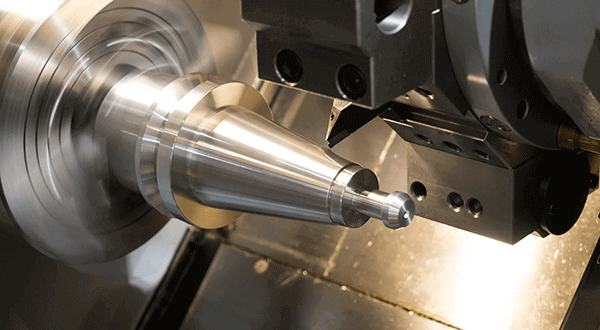

2.Turning

Turning is another machining process commonly used in CNC machines. In turning, a cutting tool is used to remove material from a rotating workpiece to create a desired shape or feature. The workpiece is held in a chuck and rotated around its axis, while the cutting tool is positioned on a tool holder that can move in different directions. The cutting tool removes material from the workpiece in the form of chips, creating a smooth and precise surface.

There are different types of turning operations that can be performed, depending on the desired outcome. Some of the most common turning operations include:

- Facing – In facing, the cutting tool is positioned perpendicular to the workpiece and removes material from the surface of the workpiece.

- Turning – In turning, the cutting tool is positioned parallel to the workpiece and removes material from the outer diameter of the workpiece.

- Drilling – In drilling, the cutting tool creates a hole in the workpiece.

- Boring – In boring, the cutting tool enlarges an existing hole in the workpiece.

- Knurling – In knurling, the cutting tool creates a pattern of raised diamond-shaped projections on the surface of the workpiece to provide better grip.

CNC turning machines also use computer programs to control the movement of the cutting tool and the workpiece, allowing for precise and repeatable machining operations. The operator enters the desired dimensions and shape into a computer program, which then generates the tool path and controls the movement of the cutting tool.

For example, let’s say you want to create a shaft for a machine using CNC turning. You would first create a CAD (Computer-Aided Design) drawing of the shaft, including all the necessary dimensions and features. Then you would input this design into the CNC turning machine, which would generate the tool path and control the movement of the cutting tool.

The machine would then use the cutting tool to remove material from the workpiece, following the programmed tool path. Once the turning operation is complete, the shaft would be removed from the machine and any finishing operations, such as polishing or coating, would be performed.

3.Grinding

Grinding is a machining process used to remove small amounts of material from a workpiece using an abrasive grinding wheel. The grinding wheel rotates at a high speed while pressing against the workpiece, removing small amounts of material to create the desired shape or surface finish. Grinding is commonly used to produce smooth and accurate surfaces on metal, plastic, and other materials.

There are different types of grinding operations that can be performed, depending on the desired outcome. Some of the most common grinding operations include:

- Surface grinding – In surface grinding, the grinding wheel is used to create a flat surface on the workpiece.

- Cylindrical grinding – In cylindrical grinding, the grinding wheel is used to create a cylindrical shape on the workpiece.

- Centerless grinding – In centerless grinding, the workpiece is held in place between two grinding wheels and rotated while the grinding wheel removes material from the workpiece.

- Internal grinding – In internal grinding, the grinding wheel is used to create a precise, smooth surface on the inside of a hole or cylinder.

CNC grinding machines use computer programs to control the movement of the grinding wheel and the workpiece, allowing for precise and repeatable machining operations. The operator enters the desired dimensions and shape into a computer program, which then generates the tool path and controls the movement of the grinding wheel.

For example, let’s say you want to create a precision gear using CNC grinding. You would first create a CAD (Computer-Aided Design) drawing of the gear, including all the necessary dimensions and features. Then you would input this design into the CNC grinding machine, which would generate the tool path and control the movement of the grinding wheel.

The machine would then use the grinding wheel to remove small amounts of material from the workpiece, following the programmed tool path. Once the grinding operation is complete, the gear would be removed from the machine and any finishing operations, such as polishing or coating, would be performed.

Related Posts

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Revolutionizing Renewable Energy with CNC Machined Components

Introduction: Renewable Energy and CNC Machined Components Renewable energy harnesses power from natural sources such as the sun, wind, and water, making it a sustainable and eco-friendly alternative to traditional…

- Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical…