Introduction to CNC Machining and the Importance of Part Marking

CNC machining, an abbreviation for Computer Numerical Control machining, represents a widely used technique in contemporary manufacturing settings. This automated process utilizes pre-programmed software to dictate movement sequences upon factory tools and equipment. A key detail within this complex operation is ‘part marking’. Part marking plays a crucial role as an identifier facilitating quality control, part traceability, branding, regulatory compliance, and more within the manufacturing industry.

- Quality control: With part marking, manufacturers can effectively manage their quality control processes which drive efficiency and product consistency.

- Part Traceability: It ensures effective tracking mechanisms for every produced component from production to market delivery.

- Branding: Companies often use part marking to embed their unique identifiers or branding elements on components, boosting recognition and value proposition.

- Regulatory Compliance: Many sectors have mandated norms requiring certain information imprinted on parts via marking for safety, standards compliance, and audit purposes.

In conclusion, with advanced techniques like laser engraving, silk screening etc., part marking has evolved into an indispensable function in modern CNC machining, considerably influencing operational productivity and output quality.

Understanding Part Marking for CNC Machining

Part marking, an integral aspect in the realm of Computer Numerical Control (CNC) machining, refers to the process by which information is embedded onto a machined part. This might take the form of serial numbers, logos or any other data necessary for identification, tracking, and quality control purposes.

In relation to CNC machining, the significance of part marking lies primarily in its ability to ensure traceability and consistency across every individual component. Each part can be accurately identified and tracked regardless of its stage within the manufacturing pipeline. It further enables rapid detection and correction of issues that may arise during the production process.

- The primary purpose of part marking involves branding and customization for business promotion and client satisfaction.

- Secondly, it contributes to operational efficiency through error identification, thereby reducing lead time and financial losses tied with faulty productions.

- Last but not least, part marking supports regulatory compliance by providing essential evidence related to manufacturing standards and product authenticity.

Hence, understanding part marking for CNC machining serves as a way to enhance overall performance of this strategic technological sphere.

Different Types of CNC Machining Part Marking Techniques

In the realm of CNC machining, several techniques prevail for part marking. These methods serve as an essential way to identify vital components, with each entailing a unique set of features and benefits. The most commonly employed techniques include laser engraving and silk screening.

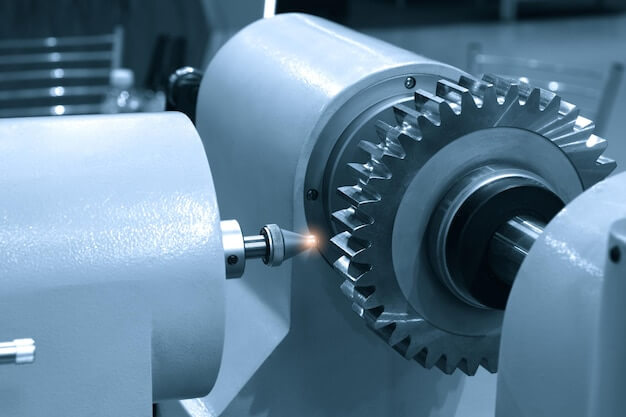

- Laser Engraving: Utilizing high-powered lasers, this method offers accuracy and efficiency, perfect for precision-based industries. It ‘burns’ designs onto the component’s surface without any physical contact, thereby reducing chances of wear and tear while ensuring high-quality markings that withstand different conditions.

- Silk Screening: Also known as screen printing, this technique applies ink through a mesh screens onto parts, especially useful for marking larger or complex shapes. Although it requires more setup time than laser engraving, silk screening is highly cost-effective for large volume production.

Understanding the Laser Engraving Process in CNC Machining Part Marking:

- Attention to detail is crucial when considering laser engraving for part marking in CNC machining.

- Text boxes should be converted into anchor points and curves to ensure readability by laser cutters.

- Laser engraving is vital to the success of part marking in CNC machining, offering precise and permanent marks on metal surfaces.

Silk Screening as a Part Marking Technique for CNC Machining

Silk screening, often referred to as screen printing, is an invaluable part marking technique used extensively in CNC machining. This process involves transferring ink onto a substrate except in areas made impermeable by a blocking stencil. A blade or squeegee helps move across the screen filling open meshes with ink, and upon lifting the screen, it leaves the ink on the material surface, producing the desired mark. Understanding the sequence of this technique can help optimize its output.

- The first step involves creating an image on the screen, followed by the application of photosensitive emulsion.

- The second step ensures proper positioning of your piece and the silk screen machine, ensuring full contact between the item and the design area to prevent blurry images.

- Finally, pressure and exposure time should be efficiently managed while pressing down the squeegee; precise control here is often directly linked to the quality of the final print.

A case in point is the applications of silk screening in the electronics industry where components like Printed Circuit Boards (PCBs) are marked effectively. Silk screening proves beneficial here due to its cost-effectiveness and ability to produce sharp, vibrant marks. Appropriate knowledge about the process, coupled with practice, will always yield optimal results when using the silk screening method for part marking.

Other Noteworthy Techniques in CNC Machining Part Marking

Having delved into laser engraving and silk screening, it’s crucial to acknowledge other remarkable techniques within the CNC machining part marking realm. Each of these techniques bears distinct features that directly impact its applicability and utility.

An excellent example is Dot Peening – a technique that involves creating indents on a surface using a pneumatic or electric pin, making it befitting for uses where resistance to harsh conditions is required. Conversely, Electrochemical Etching employs an electrolytic process designed to corrode predetermined areas leaving behind a permanent mark; ideal for metallic parts.

Then we have Inkjet Printing that leverages fast-drying ink dispelled over a component’s surface, apt for objects requiring timely execution with high-quality marking. Lastly in the notable list is Laser Annealing – this method induces oxidation beneath surfaces without causing any physical damage. This makes laser annealing perfect for medical instruments due to their need for sterilization without affecting interior components’ integrity.

- Dot Peening: Ideal for resistance to harsh conditions.

- Electrochemical Etching: Best suited for metallic parts.

- Inkjet Printing: Excellent option for time-efficient high-quality marking tasks.

- Laser Annealing: An optimal choice for medical tools that require regular sterilization procedures.

These techniques illustrate how varied and versatile the world of CNC machining part marking can be, providing multiple options echoic of different materials, durability needs, precision levels, and aesthetic appeal.

Related Posts

- Comparing Machinability of Various Tool Steels: What's the Best Choice?

Understanding Tool Steels and their Machinability Tool steels are referred to as an extensive variety of carbon and alloy steels known for their distinctive hardness, abrasion resistance, and ability to…

- From Vision to Reality: CNC Machining for Custom Furniture Design

Introduction to CNC Machining in Custom Furniture Design The advent of computer numerical control (CNC) machining has revolutionized the field of custom furniture design, allowing precise and intricate patterns to…

- High-Speed Steel vs. Carbide in CNC Tooling: Life Span and Performance Showdown?

Introduction to High-Speed Steel and Carbide in CNC Tooling In the world of Computer Numerical Control (CNC) tooling, two materials have emerged as key players: high-speed steel (HSS) and carbide.…

- Unraveling Bead Blasting in CNC Machining(cnc laser cutting Geoffrey)

CNC machining continues to be a crucial player in manufacturing due to its ability to produce complex, high-quality parts on a large scale. One of the techniques applied within this…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- CNC Lathe Machining Services for Brass Parts

CNC Lathe Machining Services for Brass Parts CNC, or Computer Numerical Control, lathe machining service is a modern manufacturing process that utilizes computerized controls to manage and manipulate machine tools…